Copyright © 2022 Foshan MBRT Nanofiberlabs Technology Co., Ltd All rights reserved.Site Map

Against the backdrop of the increasingly severe environmental pollution problem nowadays, a new breakthrough has been achieved in the field of wastewater treatment. The professional journal in the field of separation and purification technology, Separation and Purification Technology, has recently published a research paper titled "Scalable, high flux of electrospun nanofibers membrane for rapid adsorption-reduction synergistic removal of Cr(VI) ions in wastewater". The research team has successfully prepared a scalable PEI/AOPAN composite nanofiber membrane through a needleless electrospinning process and an amidoxime modification strategy, providing a highly promising new solution for the efficient treatment of wastewater containing heavy metal ions.

With the rapid development of industrialization, the amount of wastewater containing heavy metal ions discharged by industries such as mining and smelting is constantly increasing, becoming a global environmental pollution problem. Among them, hexavalent chromium ions, that is, Cr(VI) ions, although they are trace elements required by organisms, are extremely toxic when in excess and pose a serious threat to human health. The current adsorption and membrane separation technologies for treating wastewater containing Cr(VI) ions have drawbacks such as low fiber membrane spinning efficiency, long adsorption time, and difficulty in balancing the membrane separation flux and rejection rate. Based on this, the research team aimed to design and develop a new material to solve these problems. They prepared a scalable PEI/AOPAN composite nanofiber membrane through a needleless electrospinning and chemical modification strategy. This membrane can not only rapidly remove Cr(VI) ions by utilizing the adsorption-reduction synergistic effect but also has the advantages of high flux and high rejection rate. It is expected to promote the application of electrospun nanofiber membranes in actual dynamic separation and provide a more effective solution for the treatment of wastewater containing heavy metal ions.

(1) Preparation of PEI/AOPAN Composite Nanofiber Membrane

Using N,N-dimethylformamide as the solvent, PEI polymer as the adsorbent, and PAN polymer as the solute, they were mixed in a certain proportion and stirred evenly to prepare a uniform and stable spinning solution. Among them, the PEI molecular chain contains a large number of amino groups, and the PAN molecular chain contains a large number of cyano groups and a small number of ester groups.

Needleless Electrospinning: Adopting the needleless electrospinning technology, the prepared spinning solution was spun through a needleless electrospinning machine and deposited on the receiving device to obtain a PEI/PAN composite nanofiber membrane. Under the action of an electric field, the solution formed a jet during the process in the electrospinning device. During this process, the amino groups in the PEI molecular chain cross-linked with the cyano groups in the PAN molecular chain, making the PEI molecular chain stably and firmly fixed on the PAN molecular chain, and the surface of the fiber membrane was flat and smooth.

Amidoxime Modification: The collected PEI/PAN composite nanofiber membrane was subjected to amidoxime modification. It was placed in a water bath of 0.2 mol/L ammonium hydroxide, and the pH was adjusted to 7 with anhydrous sodium carbonate, and then the reaction was carried out at 65°C for 2 hours. During this process, a large number of cyano groups on the PAN molecular chain were chemically modified into oxime groups, making the surface of the PEI/AOPAN composite nanofiber membrane slightly rough and increasing the active adsorption sites.

Hot Pressing Treatment: In order to make the composite nanofiber membrane have good flatness and stability, the PEI/AOPAN nanofiber membrane was hot-pressed at 40°C. After hot pressing, the molecular chains were arranged more closely, and the surface flatness of the membrane was improved. Finally, a high-throughput nanofiber dynamic separation membrane was quickly and stably prepared.

Figure 1. SEM images of the change of functional groups in the molecular chain, the change of the network structure of the composite nanofiber membrane, and the preparation process of the composite nanofiber membrane.

(2) Comprehensive Analysis of PEI/AOPAN Composite Nanofiber Membrane

Fiber Structure and Properties:

After amidoxime modification and hot pressing treatment, the fiber structure of the PEI/AOPAN nanofiber membrane was well maintained. The results showed that after amidoxime modification and hot pressing treatment, the fiber structure of the PEI/AOPAN nanofiber membrane was well maintained, and the fiber membrane had excellent mechanical properties and hydrophilic properties. Specifically, observed by scanning electron microscopy, there were no structural damage phenomena such as fiber breakage and adhesion, providing a structural basis for its subsequent good performance. In terms of mechanical properties, the breaking strength of the PEI/AOPAN nanofiber membrane was 17.79 MPa, showing good mechanical stability. In terms of hydrophilic properties, the static contact angle of the PEI/AOPAN nanofiber membrane was 37.2°, which was significantly lower than that of the pure PAN fiber membrane, indicating that it had excellent hydrophilicity, enabling the membrane to better contact with water during wastewater treatment and improving the separation efficiency. (See Figure 2)

Figure 2 shows EDS, thermogravimetric, XRD, stress - strain, Young's modulus/breaking strength, and contact angle data for PAN, PEI/PAN, and PEI/AOPAN nanofiber membranes, with a focus on the PEI/AOPAN membrane before and after Cr(VI) adsorption.

Dynamic Separation Performance:

The dynamic separation study of the heavy metal ion solution showed that the designed nanofiber membrane could achieve high rejection (99.53%) and rapid separation (1146 L·m⁻²·h⁻¹) of a Cr(VI) ion solution with a concentration of 100 mg/L under a pressure of 0.08 MPa, meeting the discharge standard (0.5 mg/L) of Cr(VI) ions in industrial wastewater. The experimental results showed that the PEI/AOPAN nanofiber membrane performed excellently in dynamic separation performance under different pressure conditions. (See Figure 3). This result indicates that this nanofiber membrane has the ability to efficiently remove Cr(VI) ions in practical applications and can meet the strict requirements of industrial wastewater treatment. In addition, this nanofiber membrane has excellent reusability. In the experiment, after 10 adsorption-desorption cycles, the removal rate of Cr(VI) ions by the PEI/AOPAN nanofiber membrane still remained at 92.5%. This result indicates that this nanofiber membrane can still maintain a high adsorption efficiency during multiple uses, having good economic and practical value.

Figure 3 presents comparisons, influences, cyclic adsorption, a radar chart, and a mechanism diagram regarding the removal rate and flux of Cr(VI) ions by PEI/PAN and PEI/AOPAN composite nanofiber membranes under various conditions.

Principle of Metal Ion Removal:

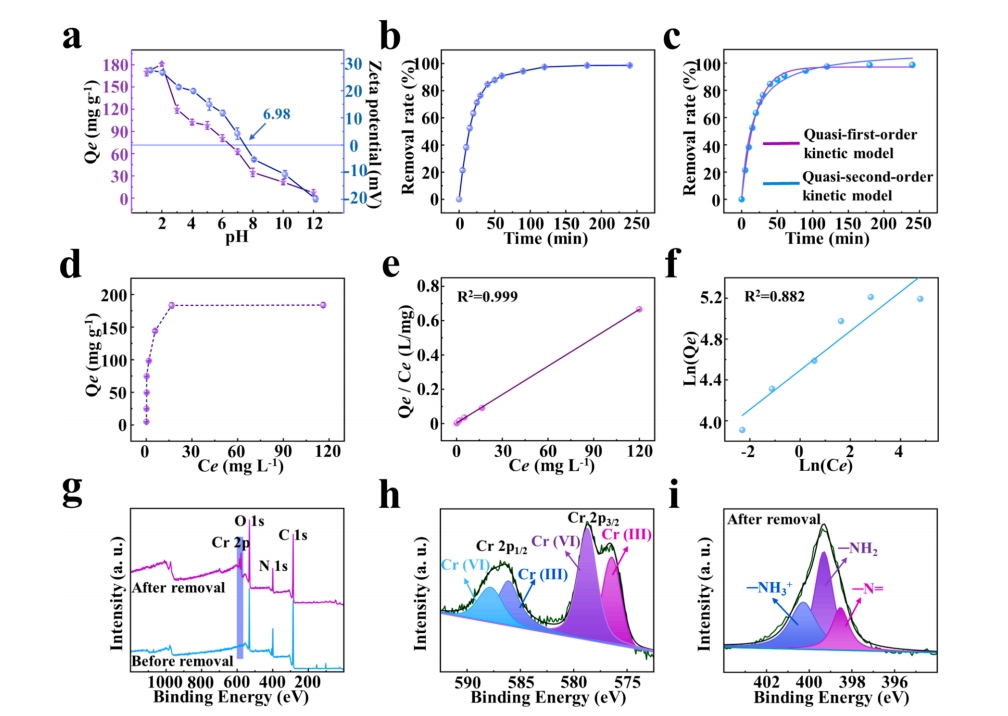

The main principle is as follows: Through the protonation of amino groups, the electrostatic adsorption of the anion HCrO₄⁻ is enhanced. In an acidic environment, the amino groups (-NH₂) on the surface of the PEI/AOPAN nanofiber membrane are protonated to form -NH₃⁺, thereby enhancing the electrostatic adsorption of HCrO₄⁻ (see Figure 4). Then, part of the Cr(VI) is reduced to Cr(III) by the consumption of protons through the electron donor (amino group). The results of XPS analysis showed that the characteristic peak of Cr(III) appeared on the surface of the nanofiber membrane after adsorption (Figure 4h), confirming the reduction process of Cr(VI). In addition, the high-yield electrospun PAN/PEI blended porous membrane modified by amidoxime can rapidly remove Cr(VI) from water and reduce Cr(VI) to Cr(III). This process not only improves the removal efficiency of Cr(VI) but also reduces environmental pollution.

Figure 4 shows the zeta potential, removal rate, kinetic models, isotherms, and XPS spectra related to the PEI/AOPAN composite nanofiber membrane's adsorption of Cr(VI) at different pH values, times, and initial concentrations.

The trade-off between flux and rejection rate is a long-standing defect of membrane separation technology for the removal of heavy metal ions in wastewater. In this study, through a needleless electrospinning and chemical modification strategy, a scalable and high-throughput polyethyleneimine/amidoxime-modified polyacrylonitrile (PEI/AOPAN) composite nanofiber membrane was designed and developed. Subsequently, the prepared nanofiber membrane was used as a membrane separation material, and through the adsorption-reduction synergistic effect, Cr(VI) ions in wastewater were rapidly and efficiently removed.

The results showed that the PEI/AOPAN composite nanofiber prepared through the needleless electrospinning and amidoxime modification processes has the characteristics of a good fiber structure, excellent hydrophilicity, good acid-base resistance stability, and excellent mechanical properties. During the dynamic separation process, this membrane can rapidly and efficiently remove Cr(VI) ions (100 mg/L) in wastewater. Under the pressure condition of 0.08 MPa, the flux is as high as 1146 L·m⁻²·h⁻¹, and the rejection rate is 99.53%. The process of removing Cr(VI) ions by this membrane follows the pseudo-first-order adsorption kinetic model and the Langmuir adsorption isotherm model. This work has confirmed the feasibility of high-capacity adsorption of porous membranes and provided the possibility for the use of adsorption membranes to remove heavy metal ions in wastewater.

Article Source: https://doi.org/10.1016/j.seppur.2024.130747