Copyright © 2022 Foshan MBRT Nanofiberlabs Technology Co., Ltd All rights reserved.Site Map

With the development of industrialization and urbanization, air pollution has become a global issue, among which PM2.5 poses the greatest threat to human health. Air filtration materials are classified into electrostatic, chemical, biological, and mechanical filtration materials according to their mechanism of action. Among them, mechanical filtration materials are widely used due to their high filtration efficiency, simple operation, and low cost. Fiber-based filters have attracted much attention because of their high filtration efficiency, low resistance, large dust holding capacity, and reusability. Although melt-blown fiber-based filters have excellent performance, electrostatic treatment is likely to lead to charge loss, reducing the filtration efficiency.

Electrospinning technology is different. It can prepare nanofibers with a diameter ranging from 10 nanometers to 1000 nanometers via electrospinning machine. Due to its high specific surface area, high filtration efficiency, and low resistance, it has become a potential alternative to melt-blown fiber-based filters. PVDF is widely used in air filtration because of its high mechanical strength, good chemical resistance, strong solvent compatibility, and high thermal stability. PVDF-HFP has more advantages than PVDF, as it has high solubility, strong hydrophobicity, and good mechanical strength. In addition, antibacterial properties are crucial for electrospun nanofiber membranes in air filtration, and ZnO nanoparticles have attracted much attention due to their antibacterial properties thanks for electrospinning machine.

Electrospun nanofiber membranes have become an ideal material for air filtration due to their unique properties. In this paper, ZnO@PVDF-HFP antibacterial nanofiber membranes were prepared by the solvothermal method and coaxial electrospinning method. The effects of the shell feeding rate and the concentration of zinc acetate dihydrate (Zn(Ac)₂·2H₂O) on the structure and properties of the membranes were studied. It was found that an increase in the shell feeding rate would reduce the fiber diameter, increase the number of nanobeads, and decrease the membrane pore size, thus improving the filtration efficiency and pressure drop. The unreacted Zn(Ac)₂·2H₂O could enhance the conductivity of the spinning solution, reduce the pore size, and improve the air filtration performance. When the shell feeding rate was 0.60 mL/h and the concentration of Zn(Ac)₂·2H₂O was 1.5 wt%, the prepared membrane showed excellent air filtration performance, with a filtration efficiency of 99.91%, a pressure drop of 80.70 Pa, a quality factor of 0.08781 Pa⁻¹, and stable performance after continuous testing for 40 minutes. In addition, the membrane has strong antibacterial activity against Escherichia coli and Staphylococcus aureus, and has application potential in multiple aspects.

1.Preparation and Structure Regulation of Nanofiber Membranes

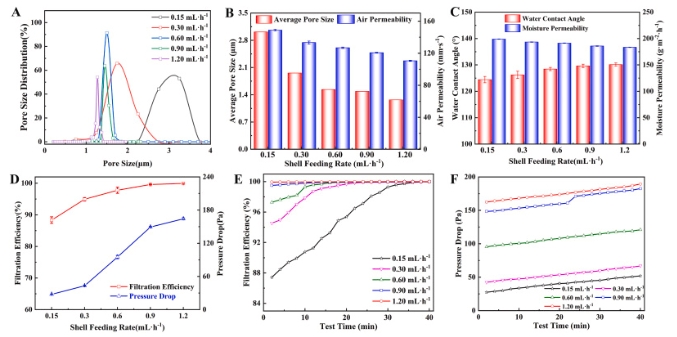

In this study, ZnO@PVDF-HFP antibacterial nanofiber membranes were successfully prepared through solvothermal reaction and coaxial electrospinning technology. It was found that the shell feeding rate and the concentration of Zn(Ac)₂·2H₂O had a significant impact on the structure and properties of the nanofiber membranes. When the shell feeding rate increased, the fiber diameter decreased and the number of nanobeads increased, thus reducing the pore size of the membrane. When the shell feeding rate was 0.60 mL·h⁻¹, the nanofiber membrane showed the best air filtration performance, with a filtration efficiency of 97.78% and a pressure drop of 95.07 Pa (Figure 1).

Figure 1: Effects of the shell feeding rate on the performance of PVDF-HFP nanofiber membranes. (A) Pore size distribution, (B) Average pore size and air permeability, (C) Water contact angle and water vapor permeability, (D) Air filtration performance, (E) and (F) Filtration efficiency and pressure drop during the 40-minute air filtration process.

2.Air Filtration Performance

The ZnO@PVDF-HFP nanofiber membrane showed excellent air filtration performance. As the concentration of Zn(Ac)₂·2H₂O increased, the pore size of the nanofiber membrane decreased, the air permeability and water vapor permeability first increased and then decreased, while the water contact angle showed the opposite trend. When the concentration of Zn(Ac)₂·2H₂O was 1.5 wt%, the filtration efficiency of the nanofiber membrane reached 99.91%, the pressure drop decreased to 80.70 Pa, and the quality factor was 0.08781 Pa⁻¹ (Figure 2).

Figure 2: Effects of the concentration of Zn(Ac)₂·2H₂O on the performance of ZnO@PVDF-HFP nanofiber membranes. (A) Pore size distribution, (B) Average pore size and air permeability, (C) Water contact angle and water vapor permeability, (D) Air filtration performance, (E) and (F) Filtration efficiency and pressure drop during the 40-minute air filtration process.

In addition, even after continuous testing for 40 minutes, the nanofiber membrane could still maintain a high filtration efficiency and a low pressure drop, showing excellent stability (Figure 1). Moreover, the nanofiber membrane showed stable filtration performance under different particle diameters, air flow rates, temperatures, and relative humidities (Figure 3).

Figure 3: Air filtration performance of M8 under different test conditions. (A) Particle diameter, (B) Air flow rate, (C) Temperature, (D) Relative humidity, (E) Running time, (F) Scanning electron microscope image after 60 minutes of air filtration.

3.Significant Antibacterial Properties

The ZnO@PVDF-HFP nanofiber membrane showed strong antibacterial activity against Escherichia coli (E. coli) and Staphylococcus aureus (S. aureus). By culturing in a medium containing model bacteria for 24 hours, it was observed that the width of the inhibition zone of the nanofiber membrane against E. coli reached 1.94 mm, and the width of the inhibition zone against S. aureus reached 2.86 mm (Figure 4 and Figure 5). ZnO nanoparticles exert antibacterial effects by releasing Zn²⁺ ions, and as the concentration of Zn(Ac)₂·2H₂O increases, the antibacterial properties are significantly enhanced.

Figure 4: Effects of the concentration of Zn(Ac)₂·2H₂O on the antibacterial performance against Escherichia coli (E. coli). (A) 0 wt%, (B) 0.5 wt%, (C) 1 wt%, (D) 1.5 wt%, (E) 2 wt%.

Figure 5: Effects of the concentration of Zn(Ac)₂·2H₂O on the antibacterial performance against Staphylococcus aureus (S. aureus). (A) 0 wt%, (B) 0.5 wt%, (C) 1 wt%, (D) 1.5 wt%, (E) 2 wt%.

4.Good Biological Safety

The ZnO@PVDF-HFP nanofiber membrane showed good biological safety and was suitable for practical applications. By culturing zebrafish in water containing the nanofiber membrane for 15 days, it was observed that the survival rate of zebrafish was high, indicating that the nanofiber membrane has good biological safety (Figure 6).

Figure 6: Digital image of zebrafish cultured in deionized water for 15 days

In conclusion, ZnO@PVDF-HFP antibacterial nanofiber membranes were successfully prepared through solvothermal reaction and coaxial electrospinning technology with an electrospinning machine. The shell feeding rate and the concentration of Zn(Ac)₂·2H₂O play a key role in determining the final structure and properties (including fiber diameter, pore size, air permeability, water contact angle, water vapor permeability, air filtration performance, and antibacterial properties, etc.). Specifically, at the optimal shell feeding rate of 0.60 mL·h⁻¹, the PVDF-HFP nanofiber membrane (M3) showed excellent air filtration performance, with a filtration efficiency as high as 97.78%, a pressure drop balanced at 95.07 Pa, and an impressive quality factor of 0.04086 Pa⁻¹. In addition, as the concentration of Zn(Ac)₂·2H₂O increased, the diameter of the nanofibers decreased slightly, and the pore size of the nanofiber membrane decreased. The air permeability and water vapor permeability first increased and then decreased, while the water contact angle showed the opposite trend.

It is worth noting that at a concentration of 1.5 wt% of Zn(Ac)₂·2H₂O, the ZnO@PVDF-HFP nanofiber membrane (M8) achieved excellent air filtration performance, with a filtration efficiency of 99.91%, a pressure drop as low as 80.70 Pa, and an excellent quality factor of 0.08781 Pa⁻¹. In addition, the addition of ZnO nanoparticles endows the nanofiber membrane with inherent antibacterial properties, highlighting its dual function as an effective air filter and antibacterial barrier. This comprehensive study not only highlights the tunability of electrospun nanofiber membranes but also paves the way for the development of advanced materials with excellent air filtration and antibacterial properties, thus verifying the important application potential of ZnO@PVDF-HFP nanofiber membranes in the field of air filtration technology (such as medical masks, medical air filters, etc.).

Article Source: https://doi.org/10.1016/j.memsci.2024.123524