Copyright © 2022 Foshan MBRT Nanofiberlabs Technology Co., Ltd All rights reserved.Site Map

Introduction:

In recent years, tissue engineering (TE) has become an alternative method to repair bone defects. How to prepare suitable, high-performance and multifunctional nanofibers is the research direction of bone tissue engineering. In view of this, this paper combs five latest studies and reviews of electrospinning technology in bone tissue engineering, for everyone to understand the latest research of Electrospinning in bone tissue engineering.

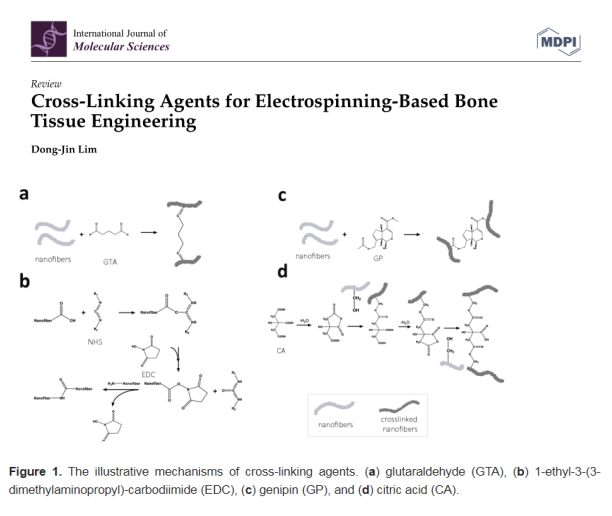

1. Electrospun crosslinking agent for bone tissue engineering

▷ Because the human body structure is similar to extracellular matrix (ECM), electrospun nanofibers are a promising bone tissue scaffold that can support bone healing. However, the lack of mechanical properties often limits their potential in bone tissue regeneration.

▷ Crosslinking agents connect electrospun nanofibers chemically is a simple and effective strategy to improve the mechanical, biological and degradation properties of electrospun nanofibers. In order to improve the mechanical properties of primary nanofibers, several crosslinking agents have been widely studied. In this review, the most commonly used crosslinking agents are studied according to the source of each crosslinking agent. Synthetic crosslinkers and natural crosslinkers have been used in electrospun bone scaffolds.

▷ Explore the combination method by using a variety of cross-linking agents or different cross-linking categories. selecting and optimizing the crosslinking scheme with appropriate reagents may be the key step to create a suitable electrospun scaffold in BTE.

DOI:doi.org/10.3390/ijms23105444

2. Electrospun porous poly (3-hydroxybutyrate-co-4-hydroxybutyrate) / lecithin scaffold for bone tissue engineering

▷ Bone tissue engineering has become a promising repair strategy for bone reconstruction and bone defect repair. It is challenging to establish a suitable scaffold with excellent porous microstructure for bone defect to promote bone repair.

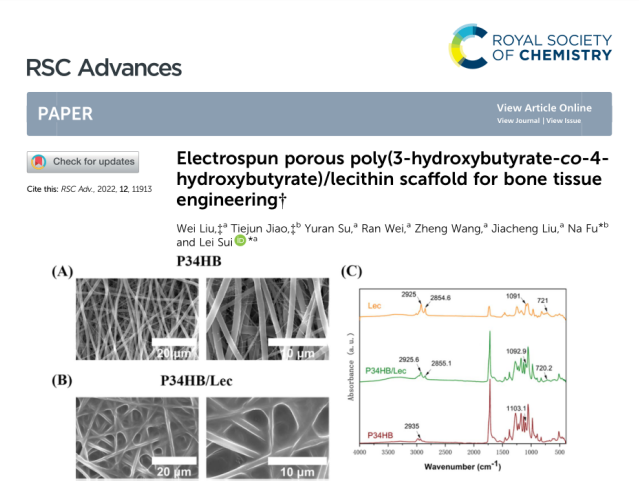

▷ In this study, electrospinning as a simple and effective technology was used to prepare a porous poly (3-hydroxybutyrate-co-4-hydroxybutyrate) (p34hb) scaffold, which was coated with lecithin. The morphology, phase composition and physical properties of the electrospun p34hb/lec scaffold were characterized. At the same time, we studied the cellular behavior of bone marrow mesenchymal stem cells, including proliferation, adhesion, migration, osteogenic differentiation and related gene expression.

▷ Finally, the biocompatibility and bone repair effect of these scaffolds were evaluated using rat subcutaneous implantation model and skull defect model respectively. In vitro results showed that these electrospun fibers were interwoven to form porous p34hb/lec scaffolds. The addition of lecithin improved the hydrophilicity of pure p34hb scaffolds, improved the efficiency of cell migration, and reduced the inflammatory reaction. The results of in vivo experiments show that p34hb/lec scaffold has good biocompatibility, can improve vascularization and promote bone regeneration.

▷ These experimental results show that the combination of nanofibers of p34hb scaffold and lecithin can play a synergistic role in promoting the osteogenesis and regeneration of bone defects; Therefore, p34hb scaffold containing lecithin shows great potential in bone tissue engineering.

DOI:doi.org/10.1039/d2ra01398c

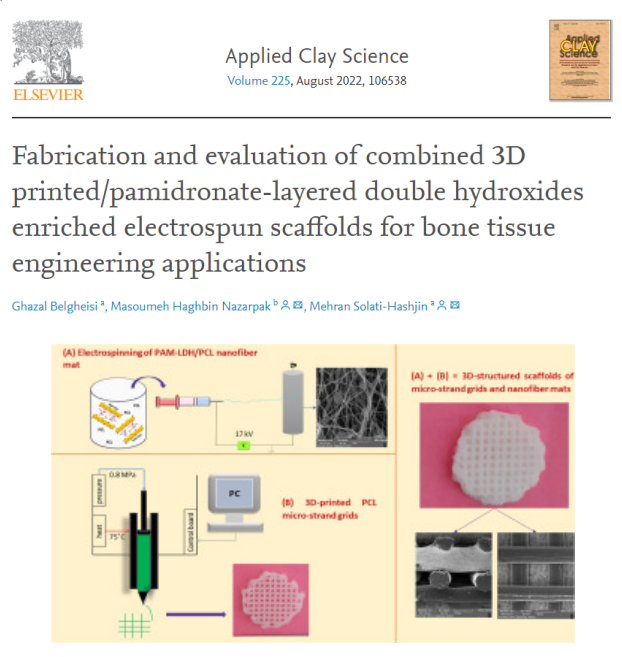

3. Preparation and evaluation of 3D printing / polyamide phosphonic acid double hydroxide composite electrospun scaffold for bone tissue engineering

▷ This study proposes a new method for the preparation and characterization of three-dimensional structure scaffolds, which are composed of pamidronate (PAM) - loaded layered double hydroxide (LDH) / polycaprolactone (PCL) electrospun nanofibers and micro strands of PCL three-dimensional printing grid. Pam-ldh was synthesized by coprecipitation method. The intercalation between PAM and LDH was confirmed by XRD and FTIR analysis.

▷ PCL and pam-ldh/pcl nanofiber mats were prepared by electrospinning. The final structure of the scaffold is obtained by bonding the nanofiber pad between the 3D printed micro strand grids. FESEM images showed that the nanofiber pad completely covered the pores of the 3D printing grid, while the fiber morphology remained unchanged. Bet analysis is used to calculate the average pore diameter, total pore volume and surface area of the support. The in vitro release monitoring of PAM can be divided into two stages; Early control of water infiltration, degradation control release period up to 28 days. The biocompatibility of the scaffold was evaluated by culturing MG-63 cell line. Scaffolds containing pam-ldh nanofiber felt highly support cell adhesion and improve alkaline phosphatase activity, which is an indicator of bone conductivity.

▷ In conclusion, these new three-dimensional structural scaffolds have potential application prospects as bone tissue engineering scaffolds.

DOI:doi.org/10.1016/j.clay.2022.106538

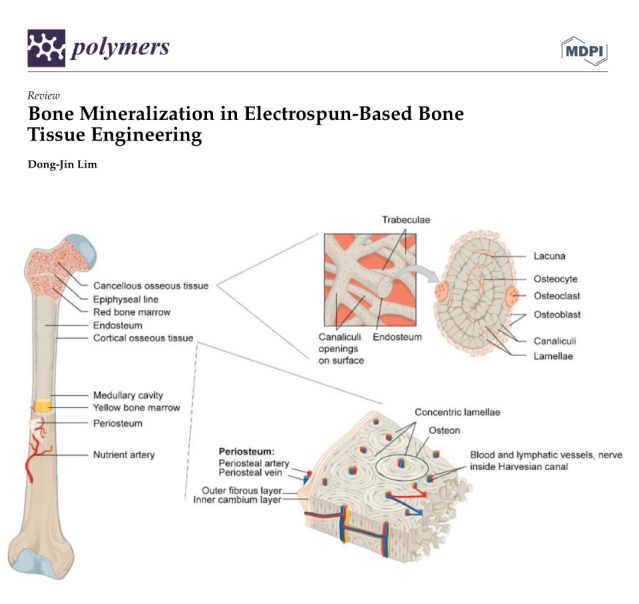

4. Bone mineralization in electrospun bone tissue engineering

▷ In the treatment of fractures (including osteoporotic fractures), the demand for bone substitutes is increasing, making bone tissue engineering (BTE) an ideal strategy to solve the continuous shortage of bone grafts. In order to simulate the natural bone mineralization of bone mineral deposition on bone matrix, a simple but effective simulated body fluid (SBF) post-processing method was used to improve the osteogenic potential of these synthetic bone grafts. Based on the importance of bone mineralization in bone regeneration, the biomineralized electrospun bone scaffolds were also reviewed. This paper reviews the potential of SBF therapy to endow biphasic characteristics of ECM structure of natural bone on electrospun bone scaffolds.

▷ In order to create functional electrospun scaffolds in BTE, the most common method is mineralized electrospun scaffolds, which enhance the osteogenic potential by simulating the natural bone ECM microenvironment, so as to achieve successful bone transplantation and repair. Incredibly, simulated body fluid (SBF) is a powerful and simple formula for inducing hydroxyapatite (HA) and apatite based inorganic clusters to the surface of electrospun scaffolds. These inorganic solutions enable us to create functional electrospun bone scaffolds that can induce bone regeneration through dynamic interactions between synthetic grafts and endogenous or exogenous cells responsible for bone regeneration.

▷ The purpose of this study is to outline the numerous electrospinning technologies used in electrospun bone scaffolds and to describe the science developed by SBF. Finally, an example of biomineralized electrospun scaffold is discussed to understand and expand the potential of biomimetic scaffold in BTE.

DOI:doi.org/10.3390/polym14102123

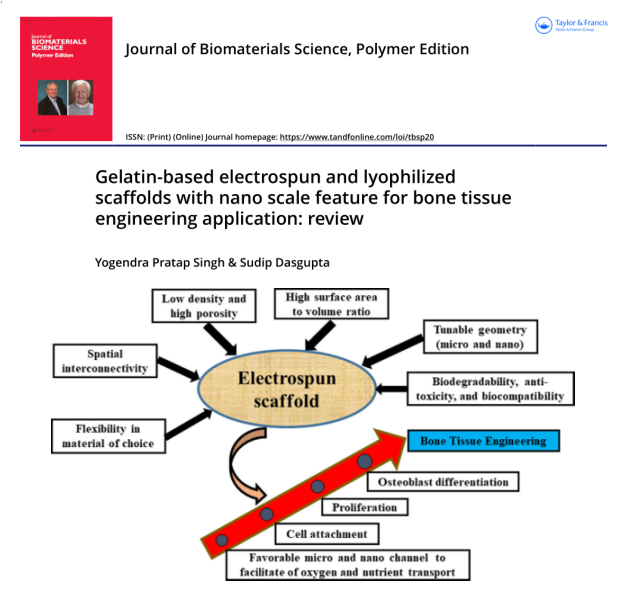

5. Research progress of nano gelatin electrospun and freeze-dried bone tissue engineering scaffolds

▷ Reconstructing the normal function of damaged human bone tissue is one of the main goals of bone tissue engineering (BTE). Prefabricated scaffolds are mostly regarded as artificial scaffolds. As scaffolds and materials for new bone tissue regeneration, they must be connected with the natural extracellular matrix of bone. The materials used to develop scaffolds shall be biodegradable, non-toxic and biocompatible.

▷ Gelatin is a potential candidate for bone transplantation, which can be mixed with other polymers or composites to improve its performance. It has physical, chemical, mechanical and biological properties. The scaffold is produced by electrospinning, self-assembly, freeze-drying, phase separation, fiber drawing, template synthesis, etc. Among them, freeze-drying and electrospun scaffolds provide a unique structure in the micro nano range, which has the required porosity and pore interconnection. It has the effect on the selective movement of biological small molecules and its role as a suitable matrix very similar to natural bone extracellular matrix.

▷ This review focuses on the characteristics and functionalization of gelatin based polymers and their composites in the form of bone scaffolds manufactured by freeze-drying and electrospinning technology and their applications in BTE.

DOI: doi.org/10.1080/09205063.2022.2068943