Copyright © 2022 Foshan MBRT Nanofiberlabs Technology Co., Ltd All rights reserved.Site Map

The development of nanofiber technology allows the originally small fibers to form a composite structure. The composite structure of nanofibers has different functions due to the different properties of the material. The core-shell structure fiber can control the thickness or structure of the core-shell layer to control the material properties, which can make the material possess optical, electrical, magnetic and other properties.

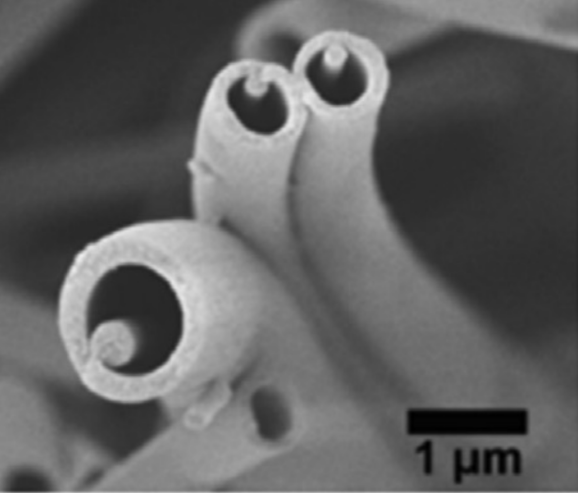

Figure 1 Microscopic image of core-shell structure fiber

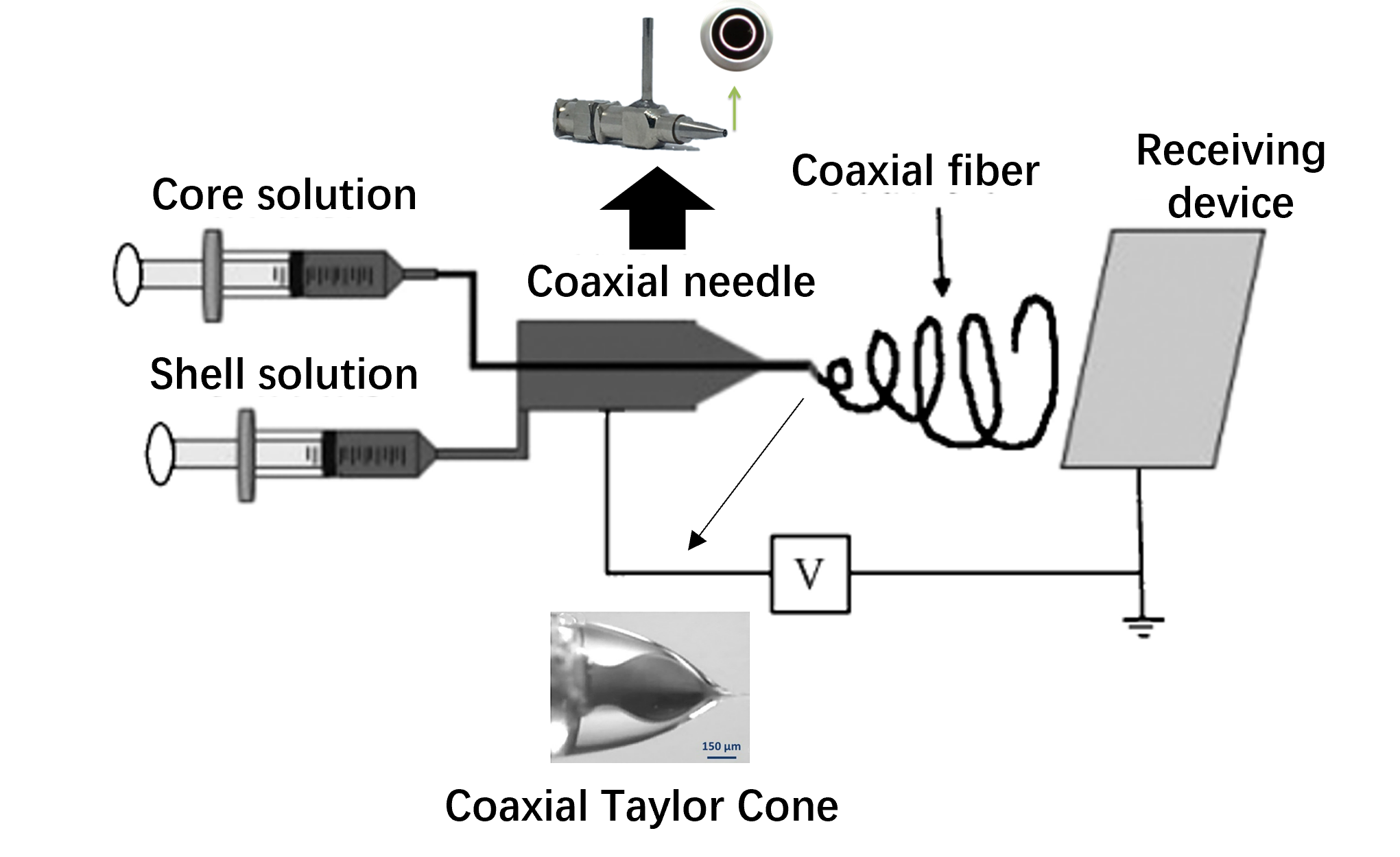

Coaxial electrospinning can compound two different polymer solutions, and the core-shell structure fiber can be obtained after the fiber is volatilized by the solvent of the polymer solution. The use of coaxial electrospinning technology can also prepare hollow fibers, which can encapsulate drugs or biological factors, and are often used in the field of biomedicine. The technology of coaxial electrospinning is relatively mature.

Figure 2 Schematic diagram of coaxial electrospinning device

In addition to the coaxial electrospinning method, the emulsion method and phase separation method can also be used to prepare core-shell structure fibers. The principle of emulsion preparation is to dissolve different materials in water and oil respectively to form a stable oil-in-water or water-in-oil emulsion structure, and use the emulsion for electrostatic spinning. The water-soluble drug is embedded in the electrospinning fiber.

The phase separation method is relatively new. In the solution system, the charges carried by the different components during the electrospinning phase separate themselves. This method does not require a multi-needle device and is simple to operate.

The application of core-shell fibers in the field of catalysis is worthy of attention. Nano-TiO2 is often used as a photocatalyst, and its shortcomings are its high specific surface area but thermal instability. Wrapping TiO2 on particles with a high specific surface area from hundreds of nanometers to a few microns can reduce the instability of nano-TiO2 and can be used to prepare materials with photocatalytic function.

In terms of drug delivery, the drug is made into a core layer structure, and the material that can control the drug release is used as the shell structure to form a core-shell structured drug release system.

The dressing made of such a structure can control the quantitative release of the drug, position the appropriate drug concentration in the body, and improve the utilization rate of the drug.

Combining electrospinning technology and photopolymerization technology to prepare core layer and shell layer fibers, respectively, can also obtain core-shell structure fibers. This method has also been proved to be feasible, and the core-shell fiber has dual response properties of temperature and pH, and has a good application prospect.

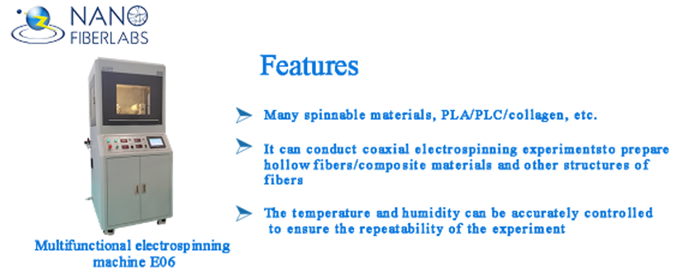

Nanofiberlabs focusing on the field of electrospinning, it produces scientific and educational electrospinning machines, pilot electrospinning equipment, nanofiber production lines, and the equipment is sold all over the world, and has a wealth of customer cases. The multifunctional electrospinning machine E06 has full functions, superior performance, and modular design; the receiving device and nozzle can be replaced, the experimental parameters can be controlled, and the coaxial needle can be matched.

multifunctional electrospinning machine E06:

https://www.nanofiberlabs.com/product/multifunctional-electrospinning-machine-e06.html

coaxial needle :

references

[1]张洪玮. 环境响应型核壳结构纤维的制备及性能研究[D].北京化工大学,2016.