Copyright © 2022 Foshan MBRT Nanofiberlabs Technology Co., Ltd All rights reserved.Site Map

Introduction: Harmful particulate pollutants (such as PM particles) in the ambient air will threaten human lung function, especially small particles smaller than 2.5 microns, which are easy to cause lung diseases. In order to improve the filtration effect of harmful particles, the introduction of air filter with electrospinning technology to enhance the removal of PM2.5 and PM10 – 2.5 has attracted extensive attention.

1. functional nanofiber membrane FNA

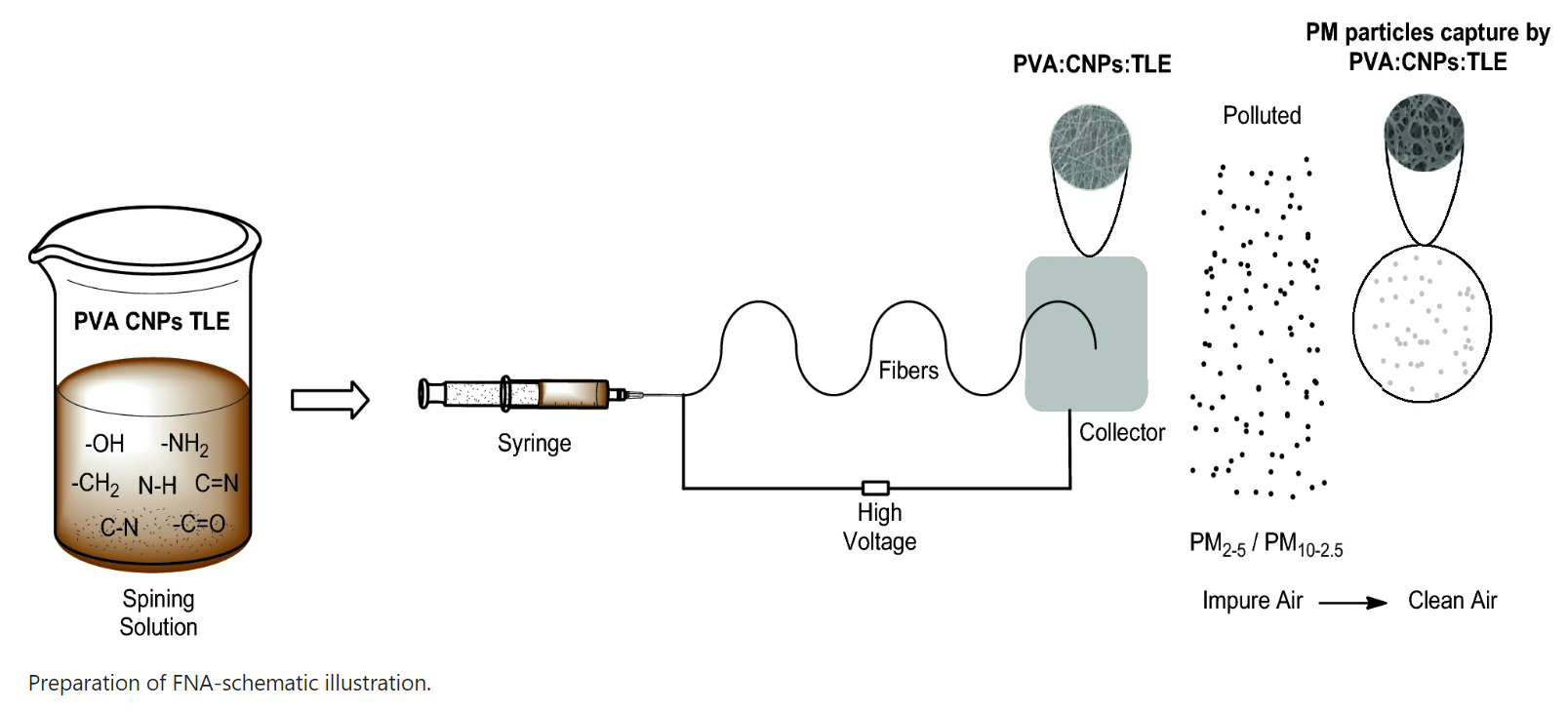

Electrospinning is a unique technology for manufacturing fibers with diameters ranging from micron to nanometer. Nano polymer based electrospun materials with average particle size are widely used in air filter applications. These materials are biocompatible, washable, reusable, and lightweight. A research team in Turkey prepared a new type of New polyvinyl alcohol (PVA) /Carbon nanoparticles(CNP) /Tea extract (TLE) functionalized nanofiber air filter (FNA) by electrospinning. The research results were published in 《scientific Reports》.

Fig. 1 Preparation of pva:cnp:tle nanofiber filter by electrospinning.

Tea extract is often used as a cheap organic adsorbent for harmful metal impurities. Carbon nanoparticles (CNP) have high solubility and stability in various common solvents, and are often used in the development of specific functional air filters. As a biodegradable and biocompatible hydroxyl polymer, polyvinyl alcohol (PVA) has chemical stability and excellent mechanical properties, which can be used to prepare functional membrane materials. The nanofiltration membrane prepared with the blend of CNPs, TLE and PVA has improved the filtration efficiency of PM pollutants, anti microbial activity and metal adsorption capacity of airborne particles.

2. Characteristics of FNA nanofiber film

The research team tested the antibacterial and UV protective properties of FNA. The antibacterial properties of PVA, pva: CNPs and pva: cnps: TL were tested. Pva: cnps: tle showed antimicrobial activity against Escherichia coli and Staphylococcus aureus. In the UV protection test, the UV generation performance of pva: cnps: tle nanofiber felt is determined by the diameter of nanofiber. Smaller apertures have been shown to produce better UV generation characteristics because they absorb UV radiation more effectively.

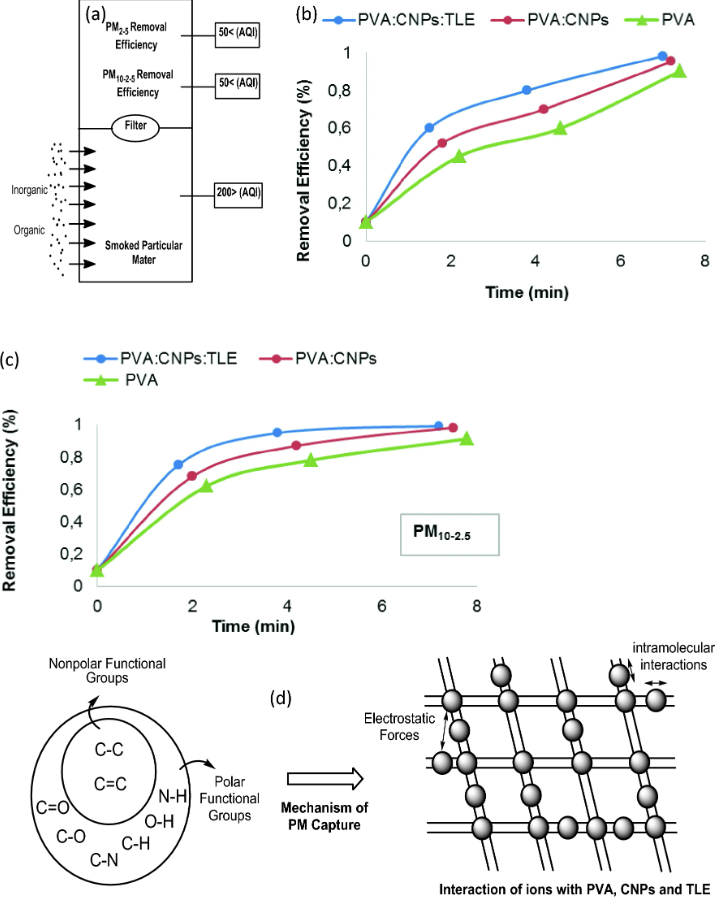

The research team designed a filter based on electrospun FNA to capture PM2.5 and pm110-2.5 particles. The results show that pva: cnps: tle nano filter has excellent PM filtration performance, and the removal efficiencies of PM2.5 and pm10-2.5 are 99.25% and 99.29% respectively.

Figure 2 (a) apparatus designed to test the capture efficiency of PM2.5 and pm10-2.5. (b) PVA, pva: CNPs and pva: cnps: PM2.5 capture efficiency of TLE (c) pm10-2.5 capture efficiency of PVA, pva: CNPs and pva: cnps: TLE. (d) Schematic diagram showing PM capture mechanism.

3. Summary

In this study, FNA has good UV protection characteristics, showing good physical, chemical, mechanical and antibacterial properties. Electrospun nanofiber membranes capture dust particles on their surfaces, which can be easily removed by backwashing or other mechanical methods. In a word, this unique pva: cnp: tle nano filter can be widely used in commercial, domestic and industrial places.

References: https://doi.org/10.1038/s41598-022-12505-w

Nanofiberlabs is a technology company focused on electrospinning research. Has many years of experience in the design and development of electrospinning equipment, and a number of patented inventions. Its equipment includes laboratory electrospinning equipment, near-field direct writing electrospinning equipment, semi-industrial electrospinning equipment, and nanofiber production lines.