Copyright © 2022 Foshan MBRT Nanofiberlabs Technology Co., Ltd All rights reserved.Site Map

Since the outbreak of theCOVID, billions of mask solid wastes have been generated every day, and the currently commonly used materials for masks, such as PP and PTFE, are not easily degradable, which has a huge impact on the entire ecological environment. In order to solve the environmental pollution of mask materials facing the world, Foshan Lepton Precision M&C Technology Co., Ltd. designed a low-cost degradable mask solution that uses all biodegradable materials by integrating resources. The specific plan is as follow:

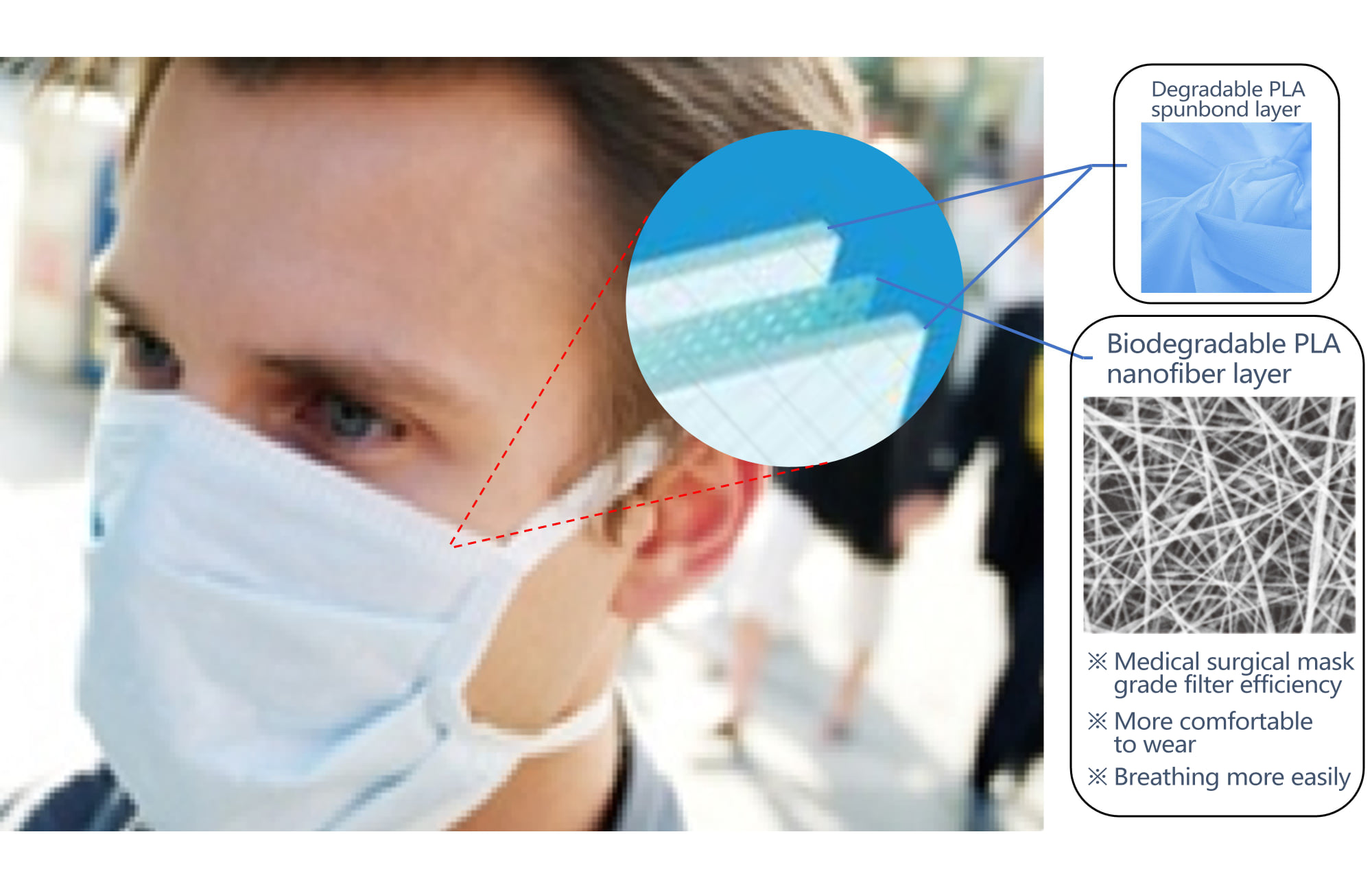

Due to the low supply of PLA meltblown cloth products on the market and the high price, the method of combining PLA non-woven fabric with nanofiber can greatly reduce the production cost of masks. Lepton provides a complete set of biodegradable nanofiber filter materials (including flat masks and degradable filter materials for N95 masks). The core function of a mask is filtration, so the most important part of the mask is the filter layer, and this mask uses nanofiber membrane as the filter layer. Compared with melt blown cloth, nanofiber membrane has obvious advantages. It not only has extremely high filtration efficiency, but also has lower resistance than melt blown cloth, which can ensure that users breathe smoothly.

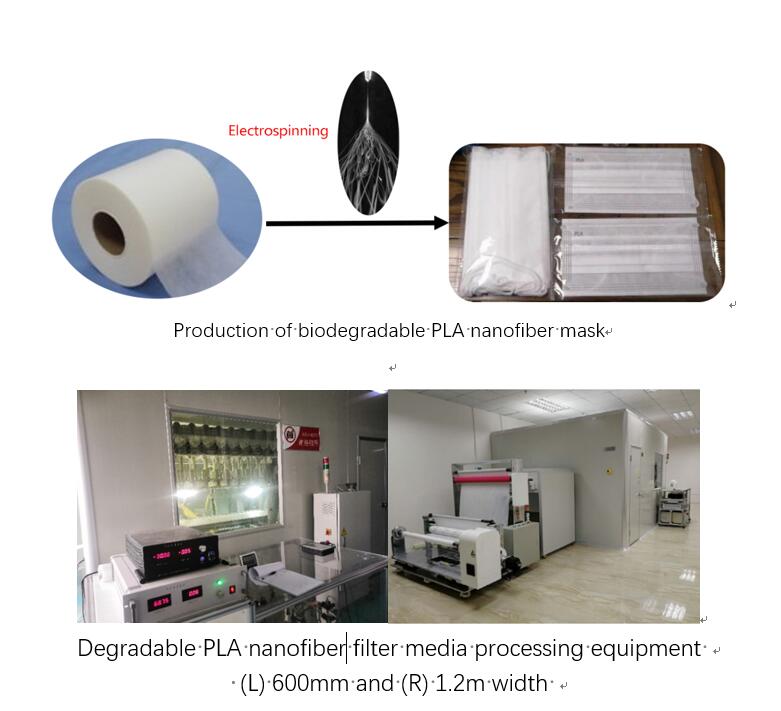

Complete production solutions for biodegradable nanofiber masks

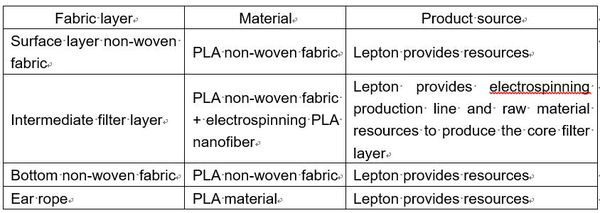

1) Material scheme:

Lepton provides a full set of degradable (PLA) mask materials, including spunbond layer, nanofiber filter layer, ear straps, nose strip, etc. Polylactic acid (PLA), as a new type of biodegradable material, is made of starch raw materials proposed by renewable plant resources (such as corn). It has good biodegradability and can be completely degraded by microorganisms in nature after use. , And finally generate carbon dioxide and water, does not pollute the environment, is very beneficial to the protection of the environment, and is recognized as an environmentally friendly material.

2)Equipment scheme:

The nanofiber production line developed by Lepton can complete the processing of the PLA nanofiber filter layer on the PLA spunbond fabric, realizing the industrialized mass production of degradable mask filter materials. The nanofiber production line equipment is easy to operate and requires less maintenance. The nanofiber layer of the PLA nanofiber filter material produced has a small diameter, large specific surface area, high porosity, and low pressure resistance, so that the filter material has high filtration efficiency, good stiffness, It has the advantages of high air permeability, strong toughness, degradability and environmental friendliness.

※ 1.2m equipment production scheme (MF03-002)

※ 600mm equipment production scheme (MF04-002)

If you want to know more about electrospinning nanofiber masks, you can contact us

WhatsApp:+86 18520902852

E-mail:info@qingzitech.com