Copyright © 2022 Foshan MBRT Nanofiberlabs Technology Co., Ltd All rights reserved.Site Map

Small-diameter vascular stents (less than 6 mm) have a huge demand in clinic, but their clinical application is limited due to the occlusion of the graft, intimal hyperplasia, and thrombosis due to the small diameter. Electrospinning and melting electrostatic printing composite manufacturing provides a new method for the manufacture of small-diameter vascular stents.

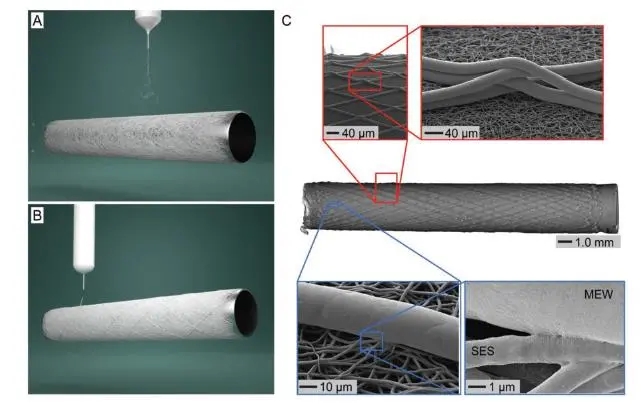

The research team from the University of Würzburg in Germany and the University of Utrecht in the Netherlands combined solution electrospinning and melt electrostatic printing to create a multi-scale double-layer tubular stent in response to the five requirements of vascular stents. The inner layer of the stent is made of polycaprolactone, a dense fiber mesh with a diameter of 1.4±0.2 μm and random orientation, made by electrospinning polycaprolactone, and the outer layer is made of the same material by melt electrostatic printing, with a controllable winding angle and a diameter of 15.2 ±4.8 μm fiber, the inner diameter of the blood vessel stent manufactured by this method is 3 mm. In addition, because the outer fiber is still above the melting point when deposited on the fiber that has been manufactured, it can be well integrated with the manufactured part, which is useful for separating the stent from the cylindrical receiver after the manufacturing is completed, and It is very important to avoid stratification of the scaffold during cell culture.

Figure 1 Manufacturing method of small diameter vascular stent

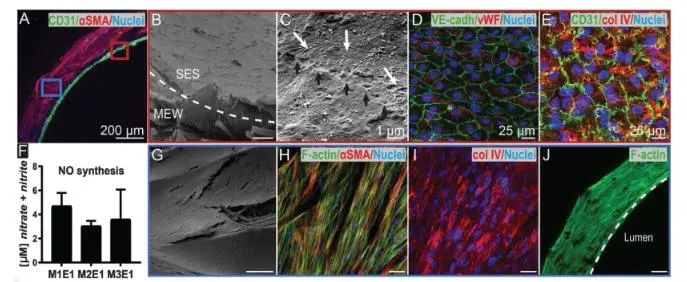

Co-cultured in vitro endothelial colony forming cells (ECFCs) and mesenchymal stem cells (MSCs) on the manufactured small-diameter vascular stents. The results showed that the inner layer of electrospun dense fibrous mesh has cell barrier properties, and the cells gathered in the electrospun layer cannot be penetrated. It is of great significance to resist the formation of thrombus before the scaffold is removed. The outer membrane with low fiber density and controllable direction is conducive to rapid cell penetration and induction of cell orientation, which solves the problem of simply using electrospinning to manufacture vascular stents. Since nitric oxide participates in platelet aggregation and is a necessary communication substance for functional endothelial cells, the synthesis of nitric oxide is detected in the cell culture system. It is proved that the endothelial cells formed on this double-layer scaffold have the function of sending signals to vascular smooth muscle cells.

Figure 2 Different protein expression and morphology of cells on small diameter vascular stents

The research team achieved the effect of inducing cell morphology and differentiation only through the design of the biomimetic structure of the scaffold without adding soluble factors or surface functional substances. This research progress provides a new direction for the manufacture and functional expression of small-diameter vascular stents.

References: Jungst T , Pennings I , Schmitz M , et al. Heterotypic Scaffold Design Orchestrates Primary Cell Organization and Phenotypes in Cocultured Small Diameter Vascular Grafts[J]. Advanced Functional Materials, 2019.