Copyright © 2022 Foshan MBRT Nanofiberlabs Technology Co., Ltd All rights reserved.Site Map

Nitrogen dioxide (NO₂) poses significant health risks to humans, and its increasing emissions due to industrial development have become a severe threat to public health. There is an urgent need for convenient NO₂ detection devices, among which portable sensors, especially smart masks, show significant advantages in real-time air quality monitoring. Semiconductor gas sensors, known for their excellent performance, hold a substantial market share. Zinc oxide (ZnO) and indium oxide

(In₂O₃) are typical semiconductor materials with gas-sensing properties. However, single-metal semiconductor sensors suffer from long response times. Therefore, researchers have been committed to developing bimetallic sensors and exploring efficient fabrication methods, such as using an electrospinning device. Among these, coaxial electrospinning can produce porous nanofibers with great application potential in gas sensing.

The study aims to develop an efficient portable gas sensor for NO₂ detection to meet the needs of air quality monitoring. In₂O₃ composite ZnO porous nanofibers were synthesized using coaxial electrospinning machine. The optimal sample (NFs.1–6) features a nanoparticle structure with interconnected pores, enhancing gas adsorption capacity and sensor performance. At 200°C, the synthesized In₂O₃@ZnO (NFs.1–6) nanofibers exhibited a high response value of 171.25 and a rapid response time of 5 s to 100 ppm NO₂. Based on these findings, a smart mask incorporating the nanofiber sensor was developed for real-time NO₂ monitoring in the air, offering an innovative approach in wearable gas sensor technology.

Researchers prepared In₂O₃@ZnO nanofibers using a coaxial electrospinning device. A precursor solution was prepared by mixing In(NO₃)₃ and Zn(NO₃)₂ with polyvinylpyrrolidone (PVP), and nanofibers were formed via electrospinning. Subsequent calcination processes removed organic components and converted the precursors into nanocrystals. The effects of different Zn-to-In mass ratios on gas-sensing properties were also investigated, with five samples (NFs.7–0, NFs.1–6, NFs.1–1, NFs.6–1, and NFs.0–7) being prepared.

Figure 1: Schematic diagram of the synthesis route.

The structural and morphological characteristics of the nanofibers were analyzed using XRD and SEM. The XRD patterns showed that ZnO was successfully doped into the In₂O₃ matrix in the NFs.1–6 sample. SEM images revealed that NFs.0–7 had a smooth surface, NFs.7–0 had a rough surface, while NFs.1–6 exhibited a porous structure, which significantly enhanced gas adsorption and sensing performance (see Figure 2).

Figure 2: (a) XRD patterns; SEM images of different composites.

TEM images showed that NFs.1–6 were composed of nanoparticles with many pores inside, which significantly increased gas adsorption capacity. HRTEM images revealed lattice fringes of In₂O₃ and ZnO with spacings of 0.292 nm and 0.247 nm, respectively, further confirming the composite structure. Elemental distribution maps showed uniform distribution of In, O, and Zn within the fibers, and EDS analysis indicated relative contents of O, In, and Zn to be 56.7%, 28.24%, and 15.06%, respectively, proving the uniformity of the material (see Figure 3).

Figure 3: TEM, HRTEM images, and elemental distribution maps.

XPS analysis revealed changes in the valence states of In and Zn in the NFs.1–6 sample, as well as a high oxygen vacancy content (67% of total oxygen). These features indicated that ZnO doping significantly altered the electronic environment of In₂O₃, enhancing gas adsorption and sensing performance (see Figure 4).

Figure 4: XPS spectra.

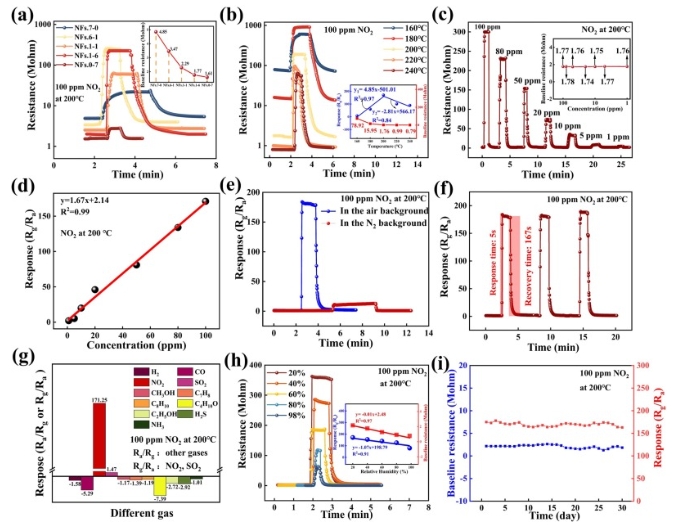

Gas-sensing tests showed that NFs.1–6 had a response value of 171.25 to 100 ppm NO₂ at 200°C, with a response time of 5 s and a recovery time of 167 s. The sensor exhibited a linear response relationship (R² = 0.99) and good humidity tolerance, maintaining stable performance over 30 days (see Figure 5).

Figure 5: Gas-sensing performance test results.

The sensing mechanism of In₂O₃@ZnO nanofibers was elucidated through energy band diagrams and schematic illustrations. The formation of an n-n homojunction significantly enhanced charge transport efficiency and suppressed electron-hole recombination, thereby improving the response speed and sensitivity to NO₂. The porous structure also increased gas adsorption capacity, further optimizing sensing performance (see Figure 6).

Figure 6: Schematic illustration of the sensing mechanism and energy band diagram.

In₂O₃@ZnO nanofibers (NFs.1–6) were successfully prepared as a rapid NO₂ sensing material using coaxial electrospinning, and a smart mask for real-time NO₂ monitoring was designed. Various tests confirmed the material's structure and properties. The sensor exhibited excellent gas-sensing characteristics at 200°C, such as fast response, good stability, and high selectivity. The stability, porous structure, and improved electron transport properties of In₂O₃ and ZnO semiconductor ceramic materials enhanced NO₂ sensing capabilities. The smart mask demonstrated potential for applications in public health and environmental protection, proving the feasibility of using coaxial electrospinning to fabricate high-performance gas sensors and the broad applicability of ceramic materials in advanced sensing technologies.

Electrospinning Nanofibers Article Source:

https://doi.org/10.1016/j.cej.2024.158872