Copyright © 2022 Foshan MBRT Nanofiberlabs Technology Co., Ltd All rights reserved.Site Map

1. High surface loading functional nanofiber membrane

Recently, the team of Associate Professor Zheng Gaofeng from the School of Aeronautics and Astronautics of Xiamen University developed a one-step preparation technology of high surface loaded functional nanofibers, which realized the rapid dispersion of graphene oxide (GO) and the simultaneous preparation of high surface loaded functional nanofibers. The PVDF/GO nanofibers prepared have high GO loading capacity, multiple adsorption sites, good hydrophilicity and strong adsorption capacity. The adsorption capacity of Cr (VI) can reach 271 mg/g and can be recycled for multiple times (>5 times). The related work was published in the international important journal Nanomaterials (impact factor 5.719, JCR Zone 2) under the title of "One Step Preparation of PVDF/GO Electrospun Nanofiber Membrane for High Efficient Adaptation of Cr (VI)".

2. Preparation and characterization of highly surface loaded nanofiber membranes

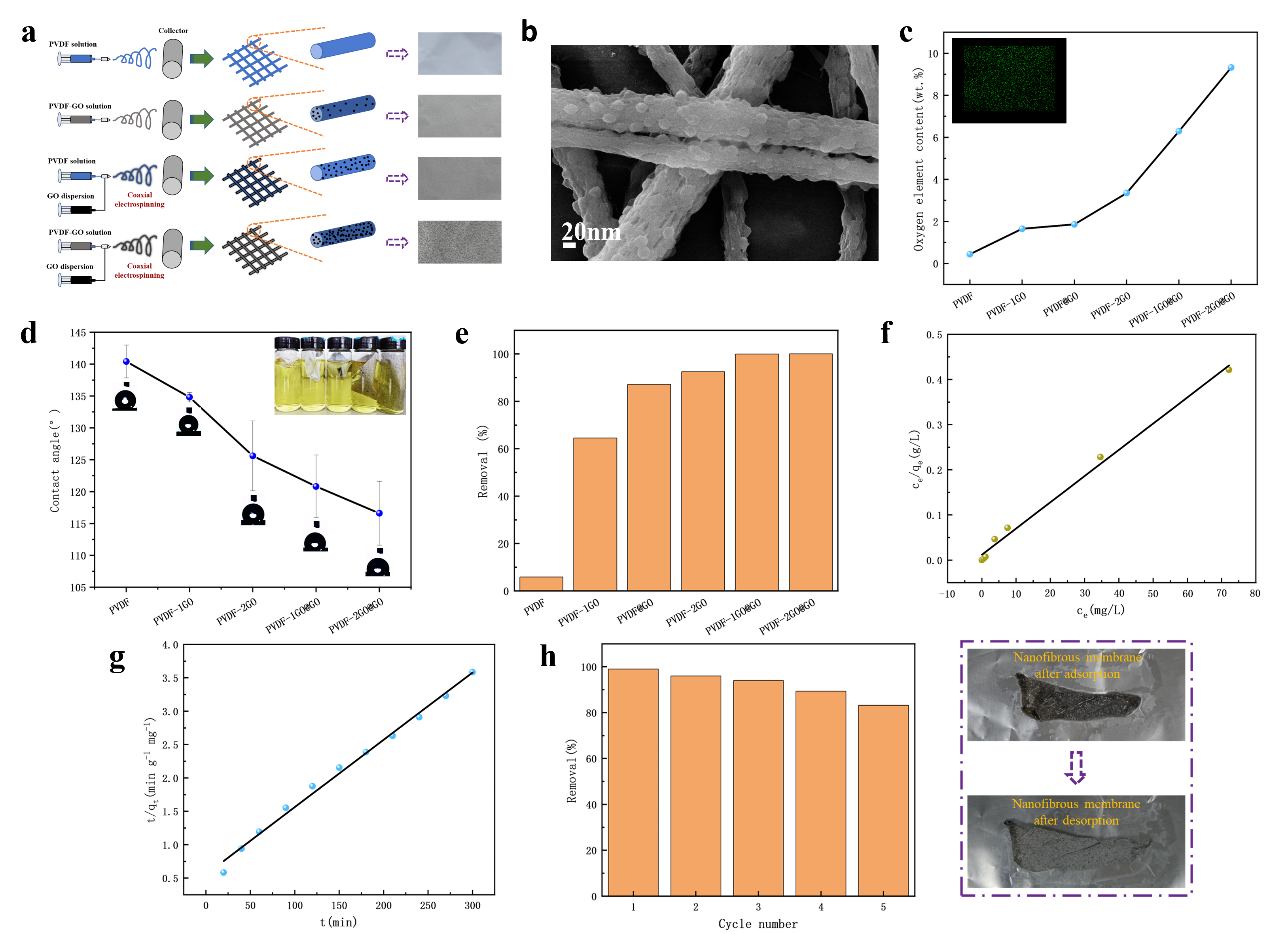

The researchers compared the nanofiber membranes prepared by different electrospinning strategies (Fig. 1a). The nanofibers changed from the original smooth surface to the rough surface with more granular protrusions (Fig. 1b), the surface oxygen content increased from 0.44% to 9.32% (Fig. 1c), the water contact angle gradually decreased from 140 ° to 117 °, and the state of immersion in the solution changed to complete immersion (Fig. 1d), which effectively proved that the surface particle load content increased significantly. In the 2h adsorption experiment, the Cr (VI) removal rate increased from 5.8% of the original PVDF membrane to more than 95%. On this basis, PVDF – 2GO@GO ENFM can reach the adsorption equilibrium within 1.5 h, and the removal rate is close to 99%, with high removal efficiency (Fig. 1e). The researchers also explored the influence of initial concentration of solution, pH value and adsorption time on the adsorption effect, and carried out a fitting analysis of the adsorption process through the quasi second order kinetic model (Fig. 1f) and Langmuir isotherm model (Fig. 1g). After five adsorption desorption experiments, the Cr (VI) adsorption and removal rate remained above 80%. At the same time, the nanofiber membrane after desorption was still well preserved, with good mechanical strength and easy treatment (Fig. 1h). The combination of coaxial electrospinning and hybrid electrospinning can effectively and maximally improve the content and utilization of adsorption sites on the surface of nanofibers, thus greatly enhancing the water treatment effect. This strategy will further promote the application of functional particles in electrospun nanofiber membranes and promote the development of water treatment.

Fig. 1 Preparation strategy and validation of high functional particle surface loading nanofibers

3. Research team introduction

Zheng Gaofeng, Associate Professor of the Department of Instrument and Electrical Engineering of the School of Aeronautics and Astronautics of Xiamen University, is the corresponding author of the paper, and Wang Qingfeng, a postgraduate of the Department of Instrument and Electrical Engineering of the School of Aeronautics and Astronautics of Xiamen University, is the first author of the paper. The research work was guided by Liu Yifang, Associate Professor of the Department of Instrument and Electrical Engineering of the School of Aeronautics and Astronautics of Xiamen University, and Li Wenwang, Associate Professor Wang Xiang, and Jiang Jiaxin, Professor of Xiamen Institute of, Shao Zungui, a graduate student of the Department of Instrument and Electrical Engineering, School of Aeronautics and Astronautics, Xiamen University, also participated in the research work of the paper. This research work has been funded and supported by the National Natural Science Foundation of China (51805460), Fujian Science and Technology Plan (2020H6003, 2021J011196, 2022H6036), Guangdong Natural Science Foundation of China (2022A1515010923, 2022A1515010949), etc.

Reference: https://doi.org/10.3390/nano12183115