Copyright © 2022 Foshan MBRT Nanofiberlabs Technology Co., Ltd All rights reserved.Site Map

1. Fabrication of ordered TPU microfiber mesh by melt electrospinning technology

The on-demand detection of sweat sensor is the core of sweat monitoring in the violent sports scene. The design and convenient manufacturing of sweat controllable sampling structure are of great significance and challenge. Recently, the team of Associate Professor Zheng Gaofeng of the School of Aeronautics and Astronautics of Xiamen University used controllable melt electrospinning technology to prepare hydrophobic thermoplastic polyurethane (TPU) flexible microfiber mesh as the sweat sampling layer to realize on-demand detection of colorimetric sweat sensor.

Through the stereo molding and precise control of the TPU microfiber, the researchers realized the gating function of the "on" and "off" states of the fibrous omentum permeability, improved the use efficiency (22 times) and stability (418%) of the colorimetric sweat sensor, and met the needs for comfort and applicability of the wearing sweat sensor in severe movement. The related work was published in IEEE Sensors Journal (impact factor 4.325, JCR upgraded zone 2, T1 journal recommended by China Instrument and Meter Society), an international important journal, under the title of "Melt Electrification Ordered TPU Microfiber Mesh for On Demand Colorimetric Wearable Sweep Detection".

2. Research innovation

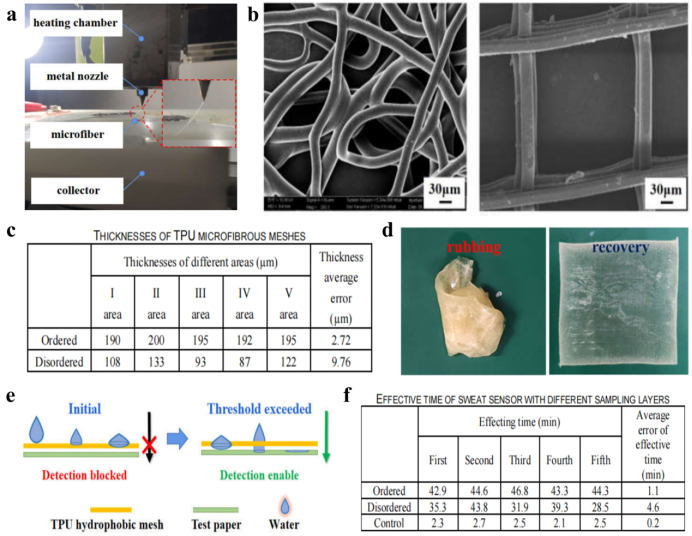

The researchers introduced micro sheath gas focusing to eliminate the spiral whipping process of TPU jet under the electric field, and studied the precise fixed-point deposition and stereo forming (Fig. 1a) to achieve the precise control of fiber direct writing grid aperture and stack layers (Fig. 1b), which increased the thickness and uniformity of TPU microfiber mesh (Fig. 1c), and the uniformity increased by 359%. TPU microfiber mesh has strong elasticity, can be easily folded and restored without damage (Fig. 1d), and has good skin adhesion to ensure the stability of the sweat detection process. In addition, the researchers studied the liquid directional transmission capability and permeable gating capability of TPU microfiber network. When the sweat is small enough to break through the hydrophobic sampling layer, the hydrophilic test paper cannot contact the sweat and the detection process cannot be started; When the sweat increases and breaks through the sampling layer, the hydrophilic test paper can contact the sweat and start the detection process (Fig. 1e). The ordered TPU microfiber mesh has uniform aperture and thickness, which can ensure a stable permeable gating function. The ability of sweat detection on demand was further studied: the average effective time of ordered microfiber web was 44.38 min, and the average error from the expected time (45 min) was only 1.1 min; The average effective time of the disordered microfiber mesh is 35.76 min, and the average error with the expected time is 4.6 min; When only test paper is included, the average effective time is 2.42 min, which is far less than the expected time (Fig. 1f). The effective time of the prepared sweat sensor can be adjusted as needed. When the sweat sensor takes effect, it means that the amount of exercise has reached the standard. Athletes can exercise or rest according to the real-time detection results to ensure personal safety. The research results provide a new idea and method for the development of controllable detection flexible sensor devices, which is helpful for the development of wearable electronics technology and has important theoretical research and engineering application value.

Fig. 1 Melt electrospun preparation, morphology, parameters and on-demand sweat detection principle of ordered TPU microfiber mesh

3. Research team introduction

Zheng Gaofeng, associate professor of the Department of Instrumentation and Electrical Engineering of the School of Aeronautics and Astronautics of Xiamen University, is the corresponding author of the paper, and Shao Zungui, a doctoral student of the Department of Instrumentation and Electrical Engineering of the School of Aeronautics and Astronautics of Xiamen University, is the first author of the paper. The research work was guided by Liu Yifang, associate professor of the Department of Instrumentation and Electrical Engineering of the School of Aeronautics and Astronautics of Xiamen University, and Li Wenwang, associate professor Wang Xiang, and teacher Jiang Jiaxin of the, Chen Huatan, Wang Qingfeng and Kang Guoyi, graduate students of the Department of Instrument and Electrical Engineering, School of Aeronautics and Astronautics, Xiamen University, also participated in the research work. This research work has been funded and supported by the National Natural Science Foundation of China (51805460), Fujian Science and Technology Plan (2020H6003, 2021J011196, 2022H6036), Guangdong Natural Science Foundation of China (2022A1515010923, 2022A1515010949), etc.

quote: https://ieeexplore.ieee.org/document/9864139

Source: School of Aeronautics and Astronautics, Xiamen University