Copyright © 2022 Foshan MBRT Nanofiberlabs Technology Co., Ltd All rights reserved.Site Map

Introduction:

Polyvinyl alcohol (PVA) electrospinning technology is a versatile and effective method for producing nanofibers with high controllability and low cost. PVA, a water-soluble synthetic polymer, has attracted widespread attention in various fields due to its excellent properties, such as biocompatibility, biodegradability, and film-forming ability. In this article, we will discuss how to utilize the electrospinning parameters to prepare high-quality PVA films, and highlight the potential applications of PVA electrospinning technology in the medical, food packaging, and environmental protection fields.

Methodology:

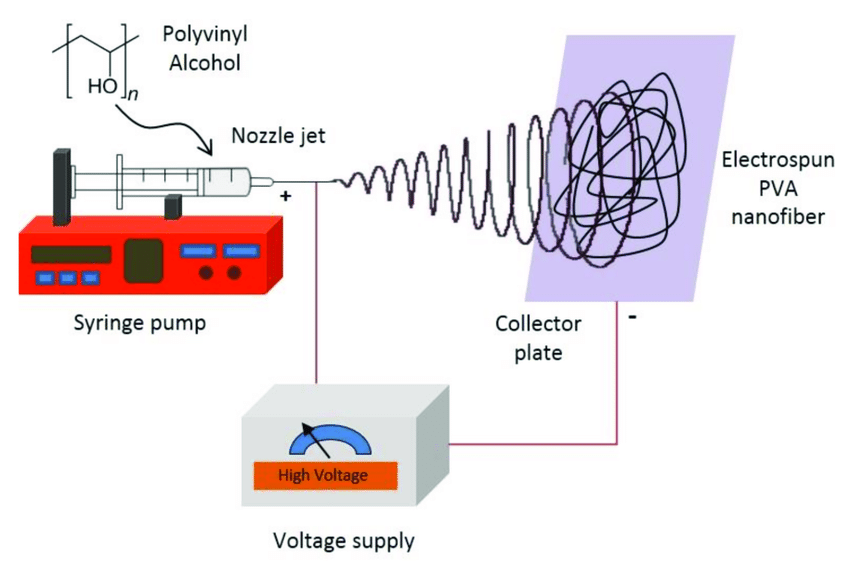

To obtain high-quality PVA films through electrospinning, several key parameters need to be carefully controlled. Firstly, the concentration of PVA solution plays a critical role. Generally, a higher concentration of PVA solution leads to thicker and more uniform nanofibers. However, if the concentration is too high, it may result in the clogging of the spinneret or poor electrospinning processability. Therefore, it is important to optimize the concentration of PVA solution according to the specific requirements of the desired film properties.

Secondly, the electrospinning voltage and distance between the spinneret and the collector also affect the morphology of PVA nanofibers. A higher voltage usually results in thinner and more uniform fibers, while a shorter distance between the spinneret and the collector leads to denser and aligned fibers. It is essential to fine-tune these parameters to achieve the desired film morphology and performance.

Additionally, the addition of other components, such as plasticizers, cross-linkers, or nanoparticles, can also influence the properties of PVA films. For example, the addition of plasticizers can improve the flexibility and mechanical properties of the films, while cross-linkers can enhance the water resistance and stability of the films. The incorporation of nanoparticles can endow the films with additional functionalities, such as antibacterial or flame-retardant properties.

Applications:

PVA electrospinning technology has shown great potential in various fields, particularly in the medical field. The biocompatibility and biodegradability of PVA make it suitable for drug delivery systems, wound dressings, and tissue engineering scaffolds. The nanofibrous structure of PVA films provides a large surface area, which facilitates drug loading and release, and allows for the mimicry of natural extracellular matrix for tissue regeneration. Moreover, PVA films can be easily modified with bioactive molecules or functional groups to enhance their performance in biomedical applications.

In the food packaging industry, PVA electrospinning technology has also found wide applications. PVA films exhibit excellent barrier properties, protecting food from moisture and oxygen, and extending the shelf life of food products, thereby reducing food waste. Furthermore, PVA films can be used for functional coatings on food packaging, such as UV blocking, haze reduction, and antimicrobial properties, adding value to food packaging materials.

In addition to medical and food packaging fields, PVA electrospinning technology has also been applied in environmental protection. PVA films with good water solubility and biodegradability can be used as environmentally friendly packaging materials, water-soluble pesticide packaging, and soil remediation materials. Moreover, PVA films can be used for the preparation of nanocomposite films by incorporating nanoparticles, such as nanoparticles, nanofibers, etc., to provide additional functionalities, such as antimicrobial, flame-retardant, and optical properties, making them promising in environmental applications.

Conclusion:

In conclusion, PVA electrospinning technology is a promising method for the preparation of high-performance nanofibers with high controllability, low cost, and versatility. Its potential applications in the medical.

Referencess:

Sa’adon, S.; Ansari, M.N.M.; Razak, S.I.A.; Anand, J.S.; Nayan, N.H.M.; Ismail, A.E.; Khan, M.U.A.; Haider, A. Preparation and Physicochemical Characterization of a Diclofenac Sodium-Dual Layer Polyvinyl Alcohol Patch. Polymers 2021, 13, 2459. https://doi.org/10.3390/polym13152459