Copyright © 2022 Foshan MBRT Nanofiberlabs Technology Co., Ltd All rights reserved.Site Map

Catalogue

1. Electrospinning PVP (polyvinylpyrrolidone)

2. Development trend of PVP based biological scaffold

3. Research on the application of electrospun PVP in biomedical products

4. Experimental parameters of electrospun PVP

1. Electrospinning PVP (polyvinylpyrrolidone)

PVP (polyvinylpyrrolidone) provides hydrophilic and lipophilic chemical properties. As an excipient, it has been used in some conventional, controlled and new drug delivery systems. Because of its solubility and availability in various grades, it provides such functions as film forming, complexing, solubilization, adhesion, stability, suspension, thickening and other functions. It is also widely used in food, cosmetics, textiles, adhesives and other industries.

PVP has been found in a large number of biomedical applications. The unique properties of PVP are amphiphilic, hydrogen bond formation and complexation, solubility, and compatibility with other polymers and therapeutic agents. With the development of electrospinning, electro spray and 3D / 4D printing, PVP has been found to be an ideal material for preparing nanofibers. This paper focuses on the application of electrospun PVP in biomedical products.

2. Development trend of PVP based biological scaffold

The inertia, chemical stability, non-toxic or low toxicity, non irritation to biological system and biocompatibility of PVP make it one of the ideal materials for electrospun biological scaffolds. Natural polymers, such as chitosan, alginate, collagen and other natural materials, can more comfortably support cell proliferation and differentiation due to their inherent compatibility with ECM. In order to overcome the limitations of natural materials, PVP, as a polymer, plays a variety of functions as an additive, stabilizer, film-forming agent and adhesive in various medical fields of biomaterial applications. It can improve the mechanical strength of natural polymers. Moreover, PVP is a synthetic hydrophilic polymer, which attracts researchers due to its excellent biocompatibility, better processability, controllable degradability, and amphiphilic nature, and can produce scaffolds with required characteristics.

The biomedical applications of PVP nanofibers or nano scaffolds in different fields are listed below, such as tissue engineering, wound dressing, drug delivery, etc. These applications are developed by electrospinning, 3D printing and some other technologies. Some researchers have used PVP as a support material (porogen) to provide porous nanofibers with better performance.

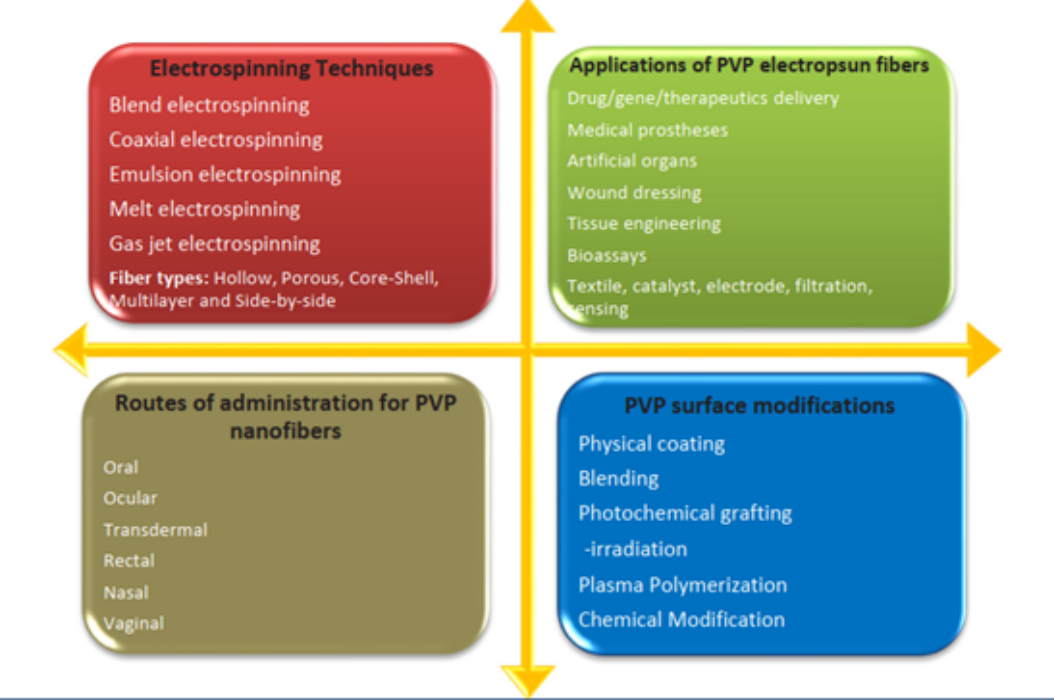

Fig. 1 PVP based nanofiber manufacturing technology, application, drug delivery route and surface modification

3. Research on the application of electrospun PVP in biomedical products

3.1 Application of PVP as human implant

PVP nanofibers have potential applications in vascular implants, dental implants, organ implants, etc. A research team developed oriented PVP nanofibers through improved electrospinning technology, which includes conductive cylindrical electrodes with parallel plates. The improved technology can produce nanofibers with lower dispersion and better performance.

These neatly arranged nanofibers can imitate natural ECM to create an ideal environment for tissue regeneration, and can also find applications in sensors. PVP is used as a composite material together with other polymers such as chitosan and carboxymethyl cellulose (CMC), which can improve the performance of the entire manufacturing system. For example, the bioexcitation and biomineralization hydrogel scaffolds of pvp-cmc-caco3 have been developed, and the influence of the concentration of ionic solution used in the preparation has been studied. Researchers said that the hydrogel scaffold showed promising results in bone tissue regeneration.

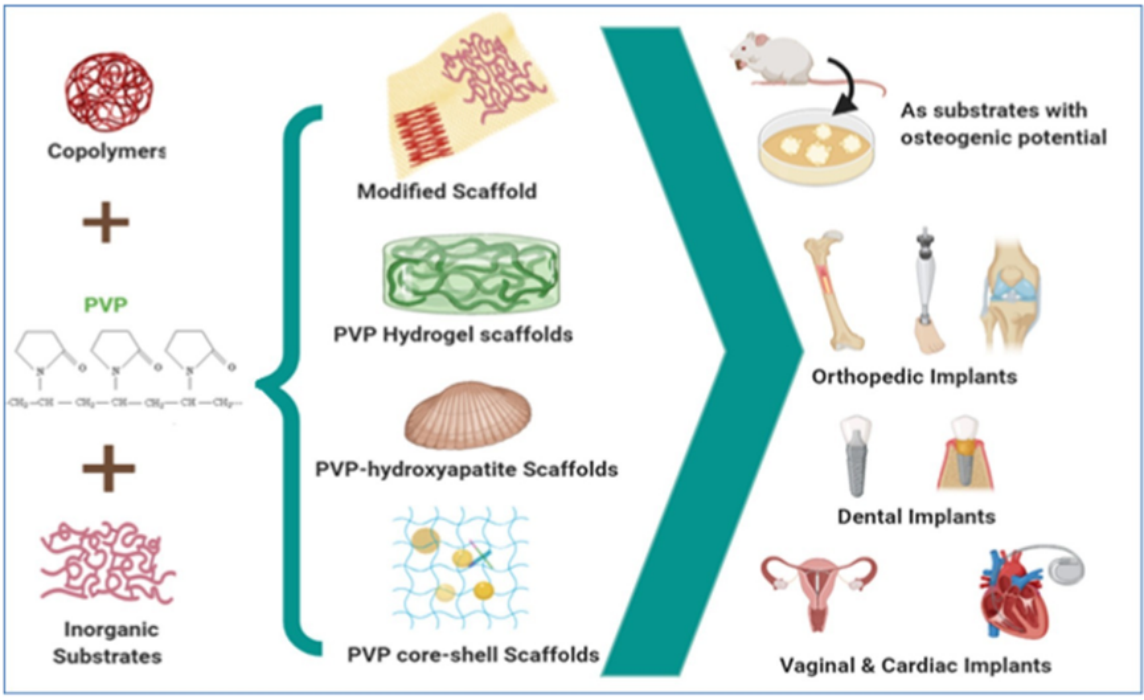

Fig. 2 Different applications of PVP nano scaffolds prepared in combination with copolymers and inorganic substrates

3.2 Application of PVP in regenerative tissue engineering

Adopt poly ε- The biocompatibility of electrospun fiber scaffolds was studied with caprolactone (PCL) and polyvinylpyrrolidone (PVP) to develop different morphologies with conditioning properties. After the scaffold was formed, PVP was extracted to improve the surface porosity, which indicated that the performance was improved. These porous fiber scaffolds with hierarchical structure show good application prospects in the field of tissue engineering.

In the field of skin tissue and wound healing, a research team has developed different proportions of aloe PVP and aloe acetate PVP electrospun fibers, and studied their microstructure, mechanical properties, antibacterial, anti-virus, anti-inflammatory and wound healing properties. These studies indicate that the latter compound of aloe acetate PVP fiber may be a potential candidate for wound healing applications.

In addition, tissue engineering of heart and vascular tissue is becoming an interesting and inspiring field. In addition to PVP alone, composites with other polymers show promising results. As a part of composite materials, PVP adds its unique characteristics to hydrophobic composite polymers, making the scaffold system have better performance. Many studies have shown that PVP/PLLA blend yarn has improved performance compared with PLLA alone, and with the increase of PVP content in the composite, the cell distribution, cell growth and cell morphology are better. Therefore, the researchers claim that PLLA-PVP microfiber membrane may become a potential scaffold for vascular tissue engineering.

3.3 PVP as a matrix for delivery of therapeutic agents

For specific diseases, drug release, such as sudden release or sustained release or targeted release, is necessary according to the required level. With advanced technology and extensive research on polymers, scientists can develop drug delivery systems in the most appropriate way to meet individual needs. PVP is such a polymer, in which therapeutic agents can be delivered according to the required characteristics.

Electrospinning is used for the formation of PVP based nanofiber felt, including research nanofiber felt and hydroxypropyl- β- The complex of cyclodextrin and meloxicam is used for rapid dissolution and taste masking. A three-layer nanofiber mesh was prepared by continuous electrospinning with zein as the top layer and bottom layer, PVP in the middle. In order to obtain better mechanical strength and drug release function, PVP was mixed with graphene oxide.

In another study, PVP mixed graphene oxide and vancomycin hydrochloride were used as the core matrix, while PCL was used as the sheath polymer to prepare core-shell nanofibers by coaxial electrospinning. The system shows time programmed biphasic drug release. It was studied in vitro and in vivo. Rat bone marrow mesenchymal stem cell lines were used for in vitro studies and rats for in vivo studies. The survival time of cells was up to 72 hours.

4. PVP experimental parameters

4.1 Preparation of PVP/PCL core sheath fiber pad by coaxial electrospinning

Material configuration: Dissolve 1.92g PCL in 16mL DCM/DMF solvent mixture (3:1, v/v) to reach the polymer concentration of 0.12g/mL as the sheath spinning solution. The core spinning solution was prepared by adding 0.6 g of PVP powder to 6 mL of water/GO aqueous solution/DMF blend solution. The volume ratio of water, GO aqueous solution and DMF is 4:0:2, 2:2:2 and 0:4:2 to adjust the content of GO in the core composition. Connect the sheath spinning and water/GO aqueous solution/DMF blend solution to the customized spinneret (outer diameter 1.3 and inner diameter 0.3 mm, respectively).

Experimental parameters: The external and internal feeding rates are controlled by two injection pumps, running at 3.0 mL/h and 0.2 mL/h. The electrostatic power supply is provided by a high voltage power supply of 18.0 kV, and the fibers are collected on aluminum foil at a distance of 14 cm. The humidity of all electrospinning processes is 25 ± 3 ° C, and the relative humidity is 55 ± 4%. The prepared fiber pad was vacuum dried for 24 hours to remove residual solvent. The same procedure was used to manufacture pharmaceutical fiber pads, with the difference that VAN was dissolved in an aqueous solution for the core spinning solution.

References: Hui Yu, Peng Yang, Yongtang Jia, Yumei Zhang, Qiuying Ye, Simin Zeng, Regulation of biological drug release behavior by graphene oxide in polyvinyl pyridine/poly( ε caprolactone) core/sheath nanofiber mats, Colloids and Surfaces B: Biointerfaces, Volume 146, 2016, Pages 63-69, ISSN 0927-7765, https://doi.org/10.1016/j.colsurfb.2016.05.052.

4.2 Customized PCL scaffold with PVP fiber and collagen/chitosan blend as skin substitute

Material configuration: chitosan (high molecular weight; degree of deacetylation=85%) and phosphate buffered saline, bovine collagen type I (AteloCollagen) and molecular weight 300 KDa, glacial acetic acid and 2-propanol (99.5%), PCL (Mn=80000), polyvinylpyrrolidone (PVP) (Mw=360000), glutaraldehyde (GA) 25% and 1,6-hexanediamine (HDA). Ethanol (99.8%). PCL at various concentrations of 15% was prepared by dissolving in glacial acetic acid to prepare 18% and 20% (w/v). Then the mixed solution was stirred gently with magnetic force at room temperature for 24 hours. Add the required deionized water and stir for 24 hours. Add 90% v/v acetic acid to each homogeneous solution, and then stir for an additional 30 minutes. In addition, 25% w/v PVP was dissolved in ethanol and gently stirred for 2 hours.

Experimental parameters: Electrospinning of PCL solution is carried out by changing the most effective parameters, including the distance (D) and voltage (V) from the nozzle to the collector. The collector speed is set to 800 rpm and is a constant experiment throughout the process. Electrospinning is carried out at room temperature with a relative humidity of about 20-25% and a 22G needle. Need to achieve the best results for bead free construction. It is used for simultaneously electrospinning PVP and PCL at different flow rates using two relative and independent spinnerets. Then the electrospun samples were immersed in water for different times to dissolve PVP fibers and the best results were selected for preparing the final samples.

References: Sadeghi avalshahr, A.R; Nokhasteh, S.; Molavi, A.M.; Mohammad-pour, N.; Sadeghi, M. Tailored PCL Scaffolds as Skin Substitutes Using Sacrificial PVP Fibers and Collagen/Chitosan Blends. Int. J. Mol. Sci. 2020, 21, 2311. https://doi.org/10.3390/ijms21072311

This article is cited from: Malesh Kurakula, G.S.N. Koteswara Rao, Moving polyvinyl pyrrolidone electrospun nanofibers and bioprinted scaffolding toward multidisciplinary biomedical applications, European Polymer Journal, Volume 136, 2020, 109919, ISSN 0014-3057, https://doi.org/10.1016/j.eurpolymj.2020.109919.