Copyright © 2022 Foshan MBRT Nanofiberlabs Technology Co., Ltd All rights reserved.Site Map

Centrifugal spinning technology is an important textile processing method that can produce fibrous materials with nano-scale fiber structures. In the field of materials engineering, centrifugal spinning technology has been widely used in various fields including biomedicine, energy, environment, textiles, electronics, and sensors. This article will review the basic principles of centrifugal spinning technology, process conditions, material characteristics and application fields.

1.Basic principles of centrifugal spinning technology

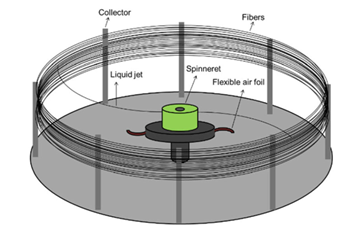

Centrifugal spinning technology is a method that uses centrifugal force to spin polymer solutions or melts into nano-scale fibers. During the centrifugal spinning process, the polymer solution or melt is first ejected through a certain spinneret device, and then under the action of the rotating centrifugal force, the polymer solution or melt is stretched into very fine fibers, and finally forms a nano-scale fiber membrane or fiber bundle on the collector. Centrifugal spinning technology is a simple, efficient and low-cost method for preparing nano-scale fibrous materials.

Figure 1 Centrifugal spinning device

2. Centrifugal spinning process conditions

The process conditions of centrifugal spinning technology include the properties of the polymer solution, the structure and parameters of the spinneret device, the centrifugal speed and temperature. For example, research has shown that fiber diameter decreases with increasing concentration, nozzle diameter, nozzle length and rotational speed. Research has shown that at 6 wt% PEO, increasing the rotational speed from 250 to 6000 rpm resulted in a significant decrease in fiber diameter (from 315 to 130 nm). When the rotational speed was increased from 7500 to 9000 rpm, the PEO fiber diameter decreased from 268 nm to 95 nm.

3. Characteristics of centrifugal spinning materials

Nano-scale fibrous materials prepared by centrifugal spinning have many unique characteristics, such as high specific surface area, high porosity, high specific strength and high specific modulus. In addition, centrifugal spinning technology can also produce nano-scale fibrous materials with different morphologies and structures, such as nano-fiber membranes, nano-fiber bundles, and nano-fiber networks. These nano-scale fibrous materials have broad application prospects in fields such as biomedicine, environment and energy.

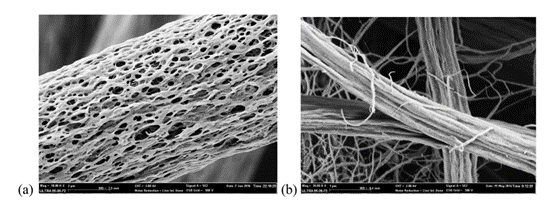

Figure 2 (a) SEM image of centrifugally spun fibers; (b) EC/PVP mixed electrospun fibers, the ratio of 90%/10%, ethanol/water ratio of 70%/30%

4. Application fields of centrifugal spinning technology

Centrifugal spinning technology has broad application prospects in fields such as biomedicine, environment, and energy.

4.1 Biomedicine

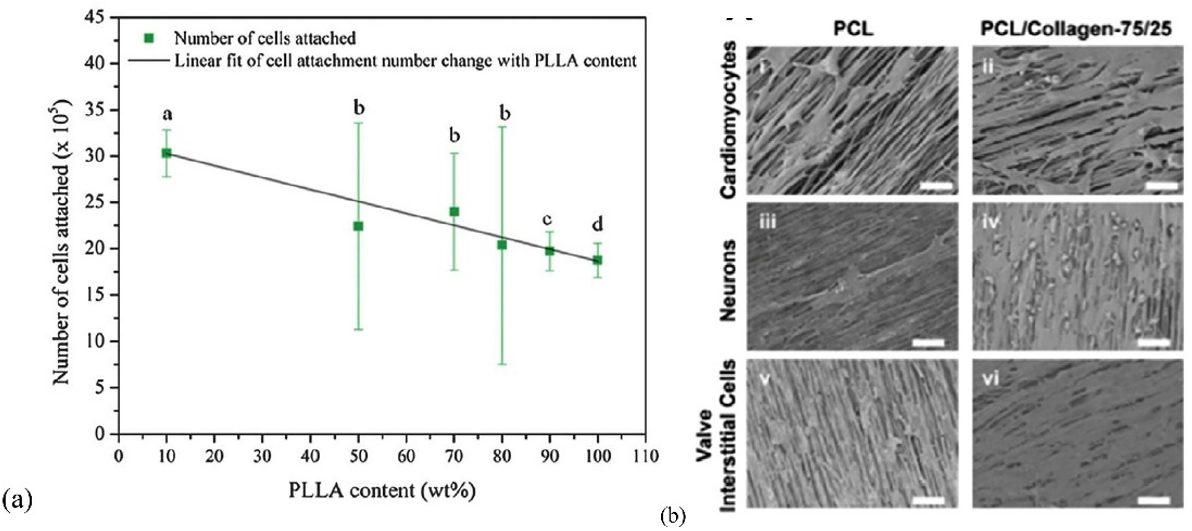

Nano-fibers are also used in many biomedical fields, such as tissue engineering scaffolds, wound healing, blood vessels, skin, and drug delivery systems. Tissue engineering is a field of biomaterials where the demand for centrifugally spun fibers is rapidly becoming important. This is because the fiber synthetic biomaterials developed in this field need to grow cells into tissues. For tissue engineering, scaffolds with aligned structures (such as nerves, muscles, and tendons) are particularly needed, and it is very important to have an aligned and interconnected pore network. A research team used centrifugal spinning to manufacture PLLA-PVP composite fiber tissue scaffolds. The PLLA/PVP mixture increased the nano-scale surface porosity and fiber hydrophilicity. A series of PLLA-PVP polymer ratios at various rotational speeds resulted in maximum fiber diameter of 7542 nm (PLLA/PVP ratio of 100:0) and a minimum fiber diameter of 63 nm (PLLA/PVP ratio of 0:100). Currently, centrifugal spinning systems are widely studied to manufacture fine-pore fibers, such as centrifugally spun PLLA/PVP mixtures, PCL, gelatin-based tissue engineering scaffolds; PCL/PVP blends and PCL-based drug delivery carriers.

Figure 3 (a) Cell attachment in PLLA/PVP composite fibers with different PLLA contents. (b) SEM images of centrifugally spun PCL and PCL/collagen blends seeded with cardiomyocytes, neurons and valve interstitial cells (VICs).

4.2 Environment

In the field of environment, centrifugal spinning technology can produce efficient nano-scale adsorbent materials, such as nano-fiber membranes and nano-fiber spheres, which can be used for the adsorption and separation of pollutants, water treatment, gas treatment, and other aspects.

The filtration process removes solids and particles, pollutants from air or liquids. Filtration efficiency, pressure drop, flux, and mechanical stability are important parameters for clean and durable filtration media. Larger particles larger than the fiber pore size are blocked on the surface of the filter. Therefore, smaller fiber diameters with high surface area are preferred in filtration applications. Nano-fibers improve filtration efficiency by improving the “slip effect” to reduce airflow resistance, which will result in a smaller pressure drop on the filtration media, providing higher filtration efficiency and relatively lower pressure drop in filtration applications. Centrifugally spun non-woven porous membranes based on silica (SiO2), PVP, thermoplastic polyurethane (TPU) and PAN have been reported as filtration media for air, aerosol, and particle filtration. Due to the highly porous and adjustable pore structure of centrifugally spun fibers and the provision of fast and inexpensive nano-fiber production with adjustable chemical and physical properties to achieve high filtration efficiency and low-pressure drop.

4.3 Energy

In the field of energy, centrifugal spinning has the characteristics of high speed, easy scaling, and high cost-effectiveness, and is an effective alternative method for manufacturing nano-fibers. These materials can be used in supercapacitors, lithium-ion batteries, solar cells, and other aspects.

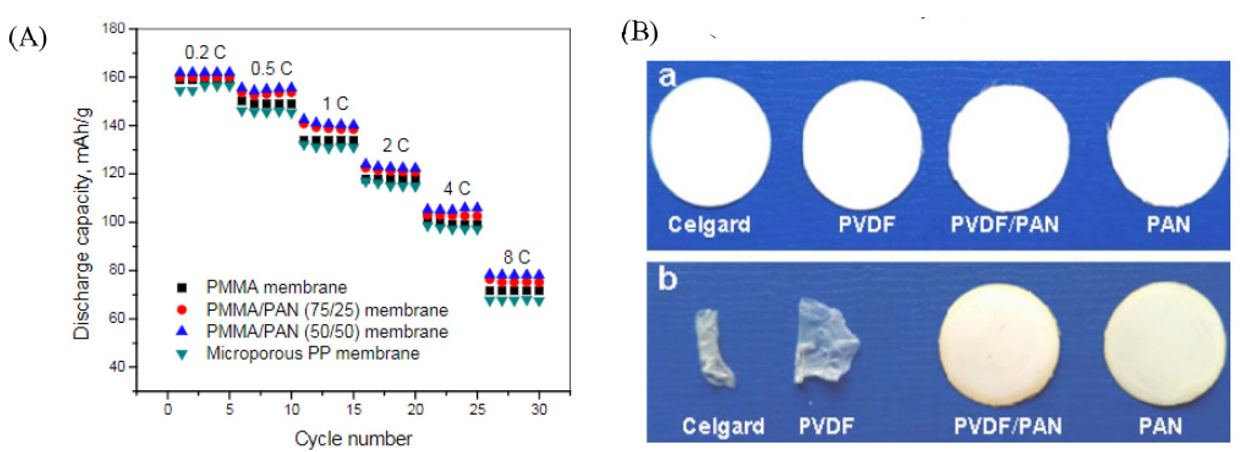

Centrifugally spun fibers are also used as separator materials for lithium-ion batteries because they have a highly porous structure and work well. There have been reports of excellent results. For example, SiO2/PAN centrifugally spun nano-fibers were studied for application as lithium-ion battery separators. The centrifugally spun 12 wt% SiO2/PAN separator was assembled into a battery (Li/LiFePO4) and the battery using the centrifugally spun separator exhibited very stable charge/discharge behavior and good cycling performance. The highest initial discharge capacity was 163 mAh/g and no significant capacity loss was observed at a charge/discharge rate of 0.2 C/0.2 C. And with increasing C rate, they showed less capacity decay. This is due to the high porosity, low interfacial resistance, and high ionic conductivity. Yanilmaz and Zhang assembled PMMA/PAN separators into Li/LiFePO4 batteries and compared their performance with commercial microporous PP membranes. The battery with PMMA/PAN (50/50) separator showed a maximum capacity of 162 mAh/g at 0.2 C. Due to the fiber structure, a high porosity of 73% and a high ionic conductivity of 3.2 mS cm-1 were achieved. Therefore, it is believed that separators based on centrifugally spun fibers can be a good alternative to high-performance lithium-ion battery separators.

Figure 4 (A) Rate performance of Li/LiFePO4 batteries containing various membranes. (B) Centrifugally spun fiber membrane (a) before heat treatment at 180°C and (b) after heat treatment for 0.5 hours.

In addition to being used as battery separators, nano-fibers can also be used as battery electrodes, anode materials, or cathode materials. Traditional battery materials have problems such as large volume changes, pulverization, leakage, expansion, explosion, and low conductivity. Nano-fibers have a high specific surface area, high porosity, good interconnected porous structure, and mechanical flexibility, which can enhance mechanical integrity.

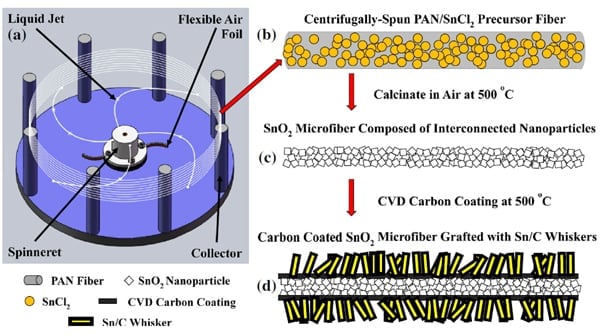

Figure 5 (A) Laboratory-scale centrifugal spinning machine; (B) PAN/SnCl2 precursor fiber; © SnO2 microfiber and; (D) Schematic diagram of carbon-coated SnO2 microfiber grafted with Sn/C whiskers.

In addition, centrifugal spinning technology can also be applied to fields such as textiles, electronics, and sensors to produce nano-scale fibrous materials with different morphologies and structures, providing new possibilities for the development of related fields.

In summary, centrifugal spinning technology, as a simple, efficient, and low-cost method for preparing nano-scale fibrous materials, has broad application prospects and is of great significance to the development and progress of the field of materials engineering.

References

Bülin Atıcı, Cüneyt H. Ünlü & Meltem Yanilmaz (2022) A Review on Centrifugally Spun Fibers and Their Applications, Polymer Reviews, 62:1, 1-64 DOI: 10.1080/15583724.2021.1901115

Centrifugal spinning device link:https://www.nanofiberlabs.com/product/centrifugal-electrospinning-machine-ce01.html