Copyright © 2022 Foshan MBRT Nanofiberlabs Technology Co., Ltd All rights reserved.Site Map

The lithium battery separator is an important part of the battery, mainly used to isolate the positive and negative electrodes, prevent short circuits, and also have a certain conductivity and transmission performance. Commonly used lithium battery separator materials mainly include the following categories:

Polyolefin materials: Polyolefin materials are the main type of lithium battery separator materials, including polypropylene (PP), polyethylene (PE), etc. These materials have excellent chemical stability, mechanical strength and thermal stability, but poor conductivity and easy thermal shrinkage.

Polyimide materials: Polyimide materials mainly include polydimethylacrylamide (PDMA), polyether ether ketone (PEEK), etc. These materials have high thermal stability, chemical stability and mechanical strength, can maintain stable performance at high temperatures, but the preparation is difficult and the cost is high.

Silicate materials: Silicate materials mainly include microporous glass fibers, ceramic membranes, etc. These materials have excellent chemical stability, mechanical strength and thermal stability, as well as good conductivity and transmission performance, but the cost is high and the preparation is difficult.

Nanofiber materials: Nanofiber materials mainly include electrospun nanofiber membranes and nanoporous membranes. These materials have excellent pore size control ability, transmission performance and conductivity performance, as well as high specific surface area and flexibility performance. They are suitable for high energy density lithium-ion batteries, but the preparation cost is high.

The above are common types of lithium battery separator materials. Different material types have different advantages and disadvantages and application ranges. Choosing the right material can improve the performance and safety of lithium batteries.

Nanofiber materials, especially electrospun nanofiber membranes, are new materials that have been widely researched and applied to lithium battery separators in recent years. Its main advantages are:

High specific surface area and porosity: The fiber diameter of nanofiber membranes is usually between tens to hundreds of nanometers, so it can have a very high specific surface area, thereby providing more electrolyte/electrode contact area. In addition, nanofiber membranes can form a three-dimensional network structure with rich pore structure. This structure can increase the permeability and transmission of electrolytes and improve the charging and discharging performance of lithium-ion batteries.

High conductivity and transmission: The conductivity and ion transmission performance of electrospun nanofiber membranes can be adjusted by controlling parameters such as fiber size and cross-point density. Compared with traditional polymer separators, nanofiber membranes can provide higher ion transmission speed and lower internal resistance, thereby improving the power performance of lithium-ion batteries.

High mechanical strength and chemical stability: Nanofiber membranes have excellent mechanical strength and chemical stability and can maintain stable performance at high temperatures and extreme environments. In addition, nanofiber membranes also have good corrosion resistance and long-term stability, which can effectively prevent short circuits and safety issues in batteries.

There are two main applications of electrospinning technology in the lithium battery industry:

One is to prepare separator materials such as high-porosity nanofiber membranes, polymer blend membranes, inorganic-polymer composite membranes to improve the mechanical properties and thermal stability of separators, reduce internal resistance, improve battery safety and cycle life.

The second is to improve the electrochemical performance of polyanion-type positive electrode materials such as lithium iron phosphate and graphite negative electrode materials by forming a conductive network or buffer layer on the surface or inside of the material through electrospinning technology to increase the contact area between active substances and conductive agents , Improve material specific capacity and rate performance.

At present, electrospinning technology still faces some challenges in the lithium battery industry, such as the uniformity, stability and scalability of nanofiber membranes, which require further research and optimization.

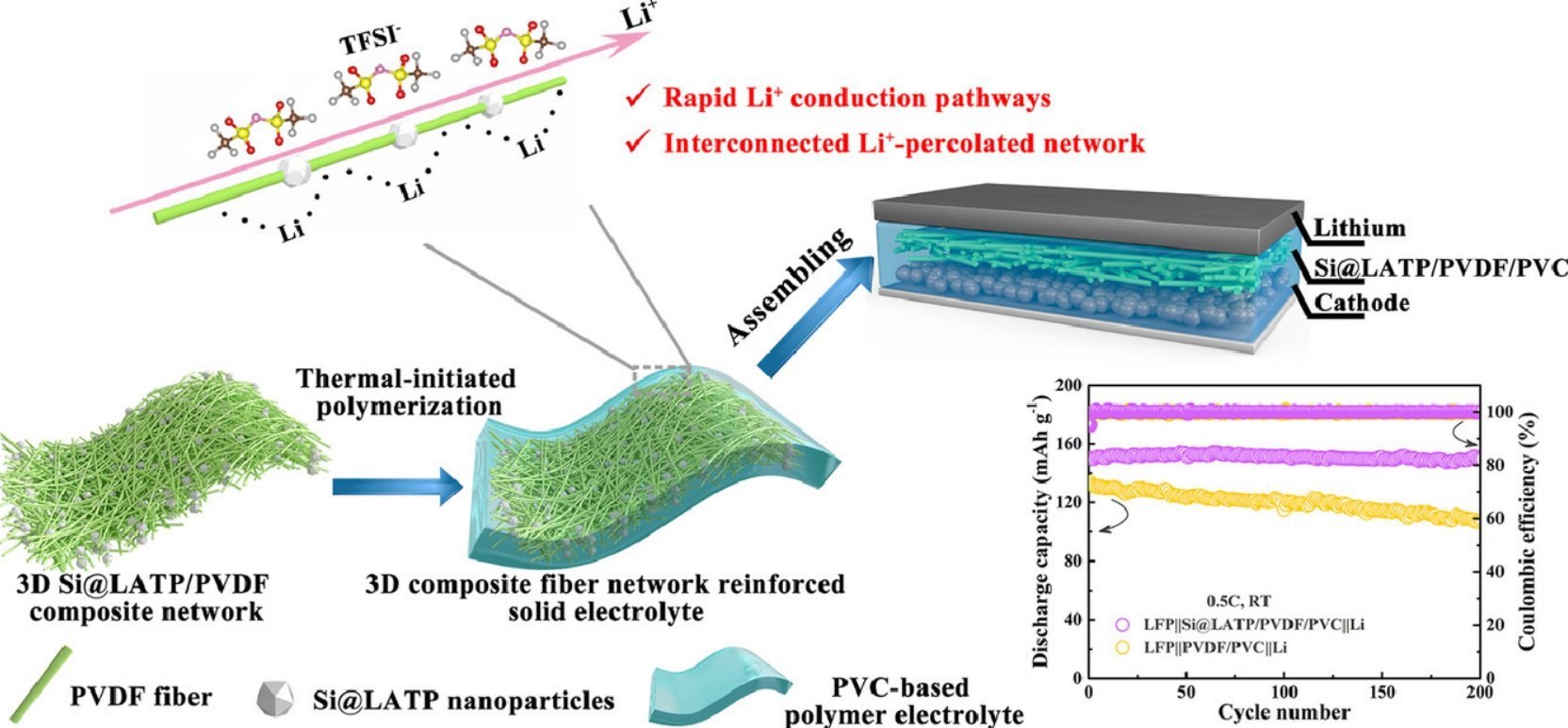

In recent years, the application of nanofiber materials in the field of lithium battery separators has continued to increase and has achieved some significant results and progress. The EnSM team of Xiong Yueping from Harbin Institute of Technology used electrospinning technology to prepare all-solid-state battery separators with high ionic conductivity and high mechanical strength. They adopted a new dual-layer structure that combines polymer fiber membranes and inorganic nanoparticle membranes to form a composite separator with high ion channel density and high interface stability. Their research shows that this separator can effectively suppress the growth of lithium dendrites and improve the safety and cycle performance of all-solid-state batteries.

Fig1 rechargeable quasi-solid-state lithium batteries

In addition, there are some other cases and studies that show the potential application of nanofiber materials in the field of lithium battery separators. For example, one study showed that polypropylene membranes prepared by electrospinning can significantly improve battery safety performance and cycle life. In addition, some studies have also explored the application of nanofiber membranes in other types of batteries such as lithium-sulfur batteries, lithium-air batteries, and sodium-ion batteries.

In general, nanofiber materials have great advantages and potential as new lithium battery separator materials, especially in terms of improving battery performance, safety and cycle life. With the continuous improvement of nanofiber preparation technology and material performance, it is believed that nanofiber materials will be more widely used in the field of lithium batteries in the future.

Reference:

Yingmin Jin, Xin Zong, Xuebai Zhang, Zhenggang Jia, Haijiao Xie, Yueping Xiong, Constructing 3D Li+-percolated transport network in composite polymer electrolytes for rechargeable quasi-solid-state lithium batteries, Energy Storage Materials, Volume 49, 2022, Pages 433-444.