Copyright © 2022 Foshan MBRT Nanofiberlabs Technology Co., Ltd All rights reserved.Site Map

1 Application Scenarios of Ceramic Fiber

Due to its low density, high temperature resistance, low thermal conductivity, good chemical stability, larger specific surface area and smaller pore diameter, ceramic fiber materials have great application prospects in thermal insulation, battery separator, catalysis and other fields.

According to chemical composition, ceramic fibers can be divided into oxide fibers, carbide fibers, nitride fibers and other ceramic fibers. Oxide fibers usually have high mechanical strength, low thermal conductivity, good electrical insulation and chemical stability, and can maintain stability in oxygen atmosphere. For example, SiO2, Al2O3, ZrO2, BN, SiC, etc. can be treated into flexible ceramic fibers.

Table 1 Application Fields

Type | Application area | |||

Thermal insulation | Aerospace | Battery diaphragm | Lightweight thermal insulation material | |

filter | Air filter | High temperature particle filtration | Oil spill treatment | Industrial organic solvent filtration |

contaminated | noise reduction | machinery equipment | engineering construction | Electromagnetic wave absorption |

catalysis | Industry | biology | Catalyst carrier | |

other | Wearable electronic devices | Nanogenerator | sensor | Responsive electrical equipment |

2 Comparison of different preparation methods

Flexible ceramic fibers are usually manufactured by one of these typical methods: centrifugal spinning, electrospinning, solution injection spinning, self-assembly, chemical vapor deposition, atomic layer deposition, polymer conversion, etc.

An important advantage of centrifugal spinning is its high output, which is two orders of magnitude higher than the laboratory scale electrostatic spinning equipment. More importantly, through reasonable design and configuration of the device, ceramic fibers with oriented structure can be obtained. When the centrifugal force is applied, the ceramic fiber can be oriented in the tangent direction relative to the spinning head to form a flexible ceramic fiber with uniform size and required mechanical properties. Its disadvantage is that it is not as flexible as electrospinning.

Table 2 Preparation Method

Methods | Material types | Advantages | Disadvantages | Fiber diameter | Industrialization prospect |

Centrifugal spinning | Melt | High efficiency | Relatively poor flexibility | > 1 μm | High |

Solution | High efficiency; broad material choice | Removal of polymer | Tens of nanometers to a few microns | Relatively high | |

Sol | High efficiency; high yield; polymer free | Ununiform diameter | Hundreds of nanometers to tens of microns | Relatively high | |

Electrospinning | Solution | Small and uniform diameter; diverse compositions and morphologies | Low efficiency; high voltage; removal of polymer | Tens of nanometers to a few microns | Relatively low |

Sol | High yield; polymer free | Nonuniform diameter; high voltage | Tens of nanometers to a few microns | Relatively low | |

Solution blow spinning | Solution | Simple and safe process; high efficiency; diverse compositions and structures | Removal of polymers | Tens of nanometers to a few microns | Relatively high |

Self-assembly | Solution | Ribbon structure | Limited material choice; low efficiency; removal of organic | Width: hundreds of nanometers to a few microns | Low |

Atomic layer deposition | Solution | Hollow structure; controllable diameter | Complicated process; low efficiency; limited material choice | Tens of nanometers to a few microns | Low |

Chemical vapor deposition | Gas | Small and uniform diameter; non-oxide component | Low efficiency; limited material choice | Tens to hundreds of nanometers | Low |

Polymer conversion | Solution | Non-oxide component | Low efficiency; calcination in inert atmosphere | Tens of nanometers to a few microns | Relatively low |

3 Ceramic fiber prepared by electrospinning

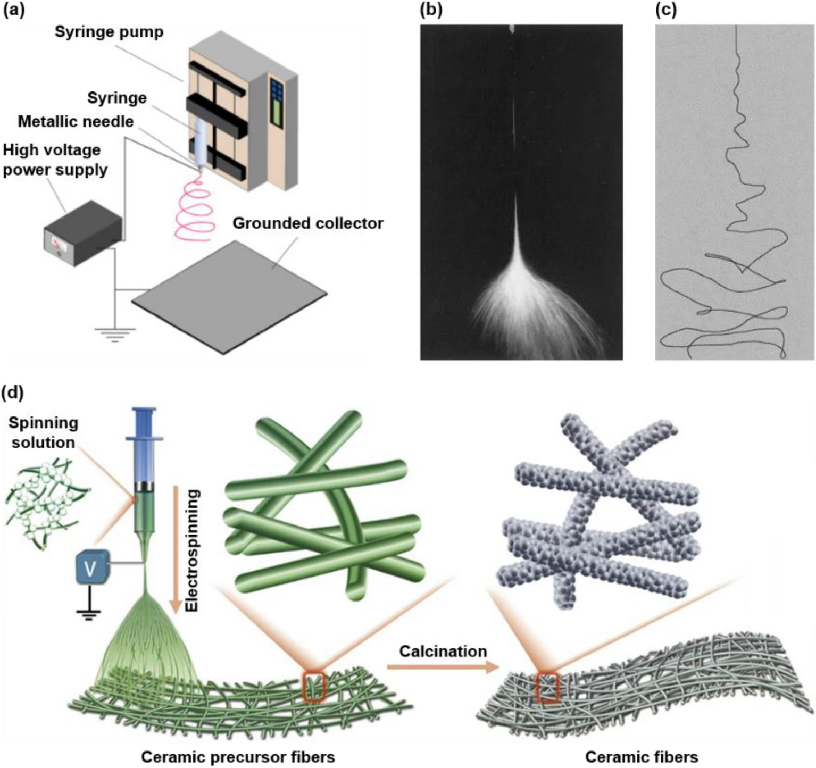

Electrospinning is one of the most commonly used methods for manufacturing ceramic fibers. Its typical steps are: (1) preparing a spinning solution containing polymer and ceramic precursor; (2) Spinning the solution into ceramic precursor fibers under an electric field; (3) Calcine at high temperature to remove organic components and residues in electrospinning. In addition, the ceramic precursor sol does not need additional polymers, and the volume shrinkage of ceramic fibers in the calcination process can be significantly reduced after electrospinning, which reduces the production cost.

Fig. 1 Preparation of flexible ceramic fibers by electrospinning. A Schematic diagram of typical electrostatic spinning equipment. B Digital image showing charged spinning solution jet, with exposure time of 1/250s. C The digital image shows the trajectory of the charged spinning solution jet in the unstable region. The exposure time is 18 ns. D Method for preparing flexible ceramic fibers by electrospinning.

The main advantage of electrospinning is that the structure and morphology of flexible ceramic fibers can be controlled by adjusting the composition of precursor solution or changing the spinning and calcining conditions.

Nitrogen doped hollow SiC fiber pad was prepared by electrospinning method and polymer precursor conversion method. The fiber pad showed good thermal insulation performance, and the electromagnetic wave absorption performance of composites with arrayed SiC nanofibers developed by this method was better than that of randomly arrayed SiC nanocomposites.

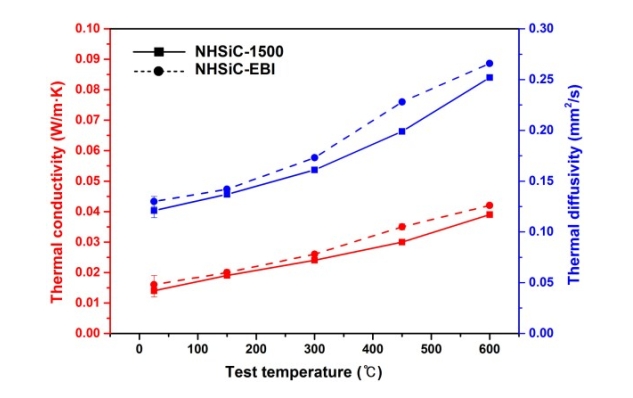

Fibers prepared from polymer precursor by coaxial electrospinning, thermal or electron beam irradiation curing process and pyrolysis process, wherein the thickness of cavity wall of hollow structure is about 1.5μm. Crystalline patterns were obtained after pyrolysis at over 1300 ℃ in nitrogen atmosphere. These nitrogen doped hollow SiC fiber pads, which are easy to manufacture, have good flexibility, incombustibility, high thermal stability, corrosion resistance and light weight (0.218g/cm−3). The ultra-low thermal conductivity of (0.026±0.039 W · m-1 · K−1) enables this pad to meet the requirements of important applications such as high-temperature insulation materials, high-temperature catalyst support materials or diesel particulate filters.

Fig. 2 Thermal conductivity and thermal diffusivity of NHSiC-1500 and NHSiC-EBI fibers at high temperatures.

Compared with other methods, the ceramic fiber produced by electrospinning shows smaller and more uniform diameter. As we all know, the fiber diameter has a significant impact on the filtration performance, which improves the filtration performance of ceramic fiber materials to a certain extent.

References:

1.Jia, C., Xu, Z., Luo, D. et al. Flexible Ceramic Fibers: Recent Development in Preparation and Application. Adv. Fiber Mater. 4, 573–603 (2022).

2.Yan J, Zhao Y, Wang X, Xia S, Zhang Y, Han Y, Yu J, Ding B. Polymer template synthesis of soft, light, and robust oxide ceramic flms. Science 2019;15:185–95.

Centrifugal electrospinning machine CE01:https://www.nanofiberlabs.com/product/centrifugal-electrospinning-machine-ce01.html

Electrospinning machine E06:https://www.nanofiberlabs.com/product/multifunctional-electrospinning-machine-e06.html