Copyright © 2022 Foshan MBRT Nanofiberlabs Technology Co., Ltd All rights reserved.Site Map

With the rapid development of Internet of Things technology, the demand for portable gas sensors is growing. Metal oxide semiconductors (MOS), as one of the most traditional and deeply researched gas sensing materials, are widely used to prepare various commercial gas sensors. Professor Lu Hongliang of Fudan University introduced the latest research progress of flexible room temperature (FRT) gas sensors based on MOS from the aspects of sensing mechanism, gas sensing performance, flexible characteristics, and main applications. Its achievements were published in Nano-Micro Letters.

1. Research highlights

(1)The recent development of flexible room temperature gas sensors based on metal oxide semiconductors (MOS) is reviewed.

(2)The flexible room temperature (FRT) gas sensors based on original MOS and MOS modified with noble metal nanoparticles, organic polymers, carbon-based materials, and transition metal disulfide materials are reviewed in detail.

(3)This paper introduces the gas sensing mechanism of the MOS chemical resistance gas sensor and puts forward the application, development prospects, and challenges of the FRT gas sensor.

2. Application introduction of metal oxide semiconductor flexible room temperature gas sensor

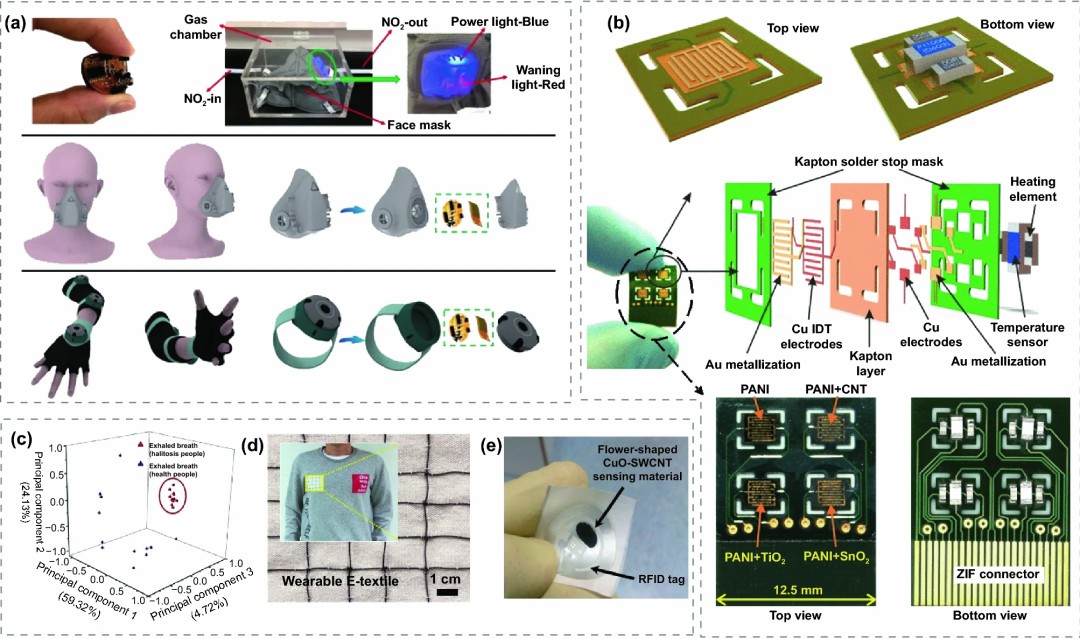

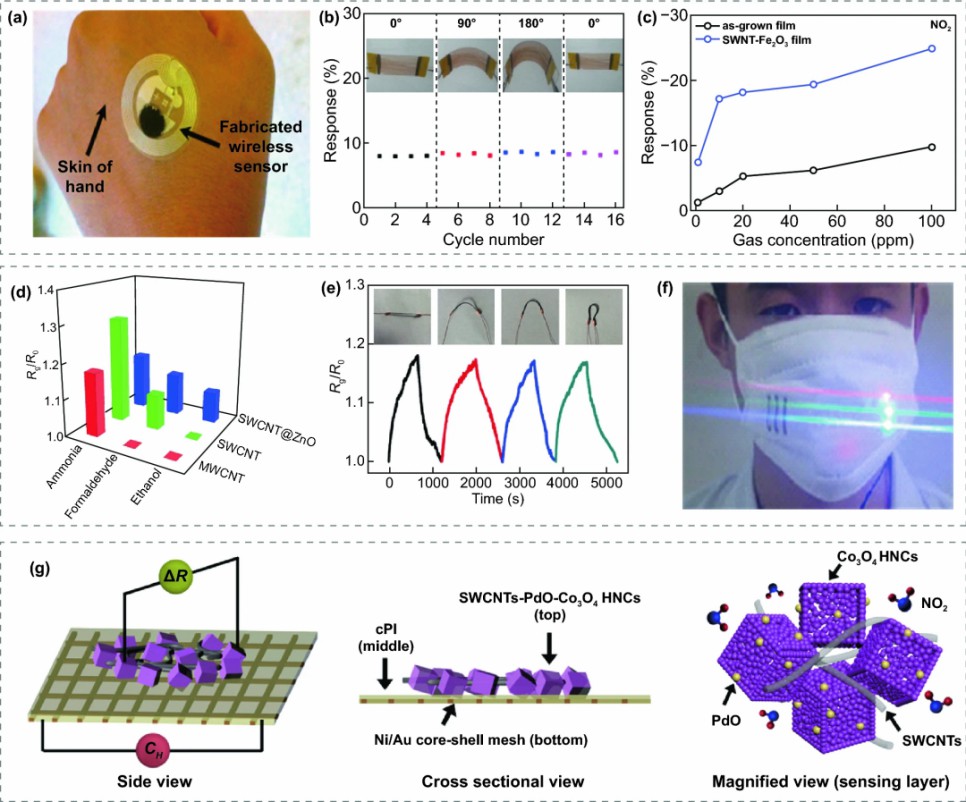

Gas sensors are widely used in smart homes, food safety monitoring, public safety, medical care, medical diagnosis, environmental protection, and industrial/agricultural monitoring. Some emerging applications, including edible electronic capsules, electronic skin, and intelligent electronic noses, put forward higher requirements for low working temperature, high gas sensing performance, good anti-interference ability, and stable mechanical flexibility of gas sensors. At present, MOS-based FRT gas sensors have been reported to be used in multiple detection sensor arrays and wearable devices, such as smart masks, gas-sensing watches, electronic textiles, etc.

Fig 1 (a) FRT NO2monitoring system and wearable applications of smart masks and smart watches; (b) Extended view, structure composition and physical demonstration of sensor array based on PANI/MOS; (c) 3D feature space of principal component analysis of RGO/ZnO hybrid materials on different exhaled gases of healthy individuals and patients with halitosis; (d) 5 × 5 Gas sensor array network is used for wearable electronic spinning; (e) Wireless RFID gas sensor

3.Various preparation methods of metal oxide flexible sensors

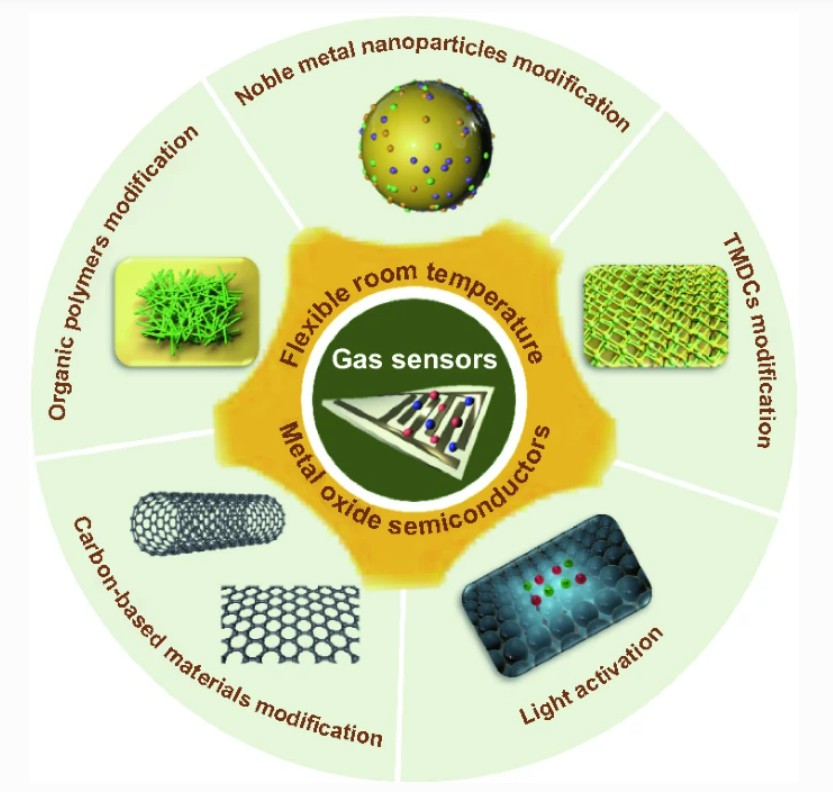

Fig 2 Implementation strategy of high-performance FRT MOS chemical resistance gas sensor

Strategy and method

3.1 MOS FRT Gas Sensor Modified by Precious Metal Nanoparticles

The surface modification of precious metals can be carried out through chemical sensitization and electronic sensitization. Chemical sensitization increases the chemical reaction rate between the target gas and the chemically adsorbed oxygen through the catalysis of noble metal nanoparticles, which is conducive to easier electron migration, thus enhancing the performance of the sensor.

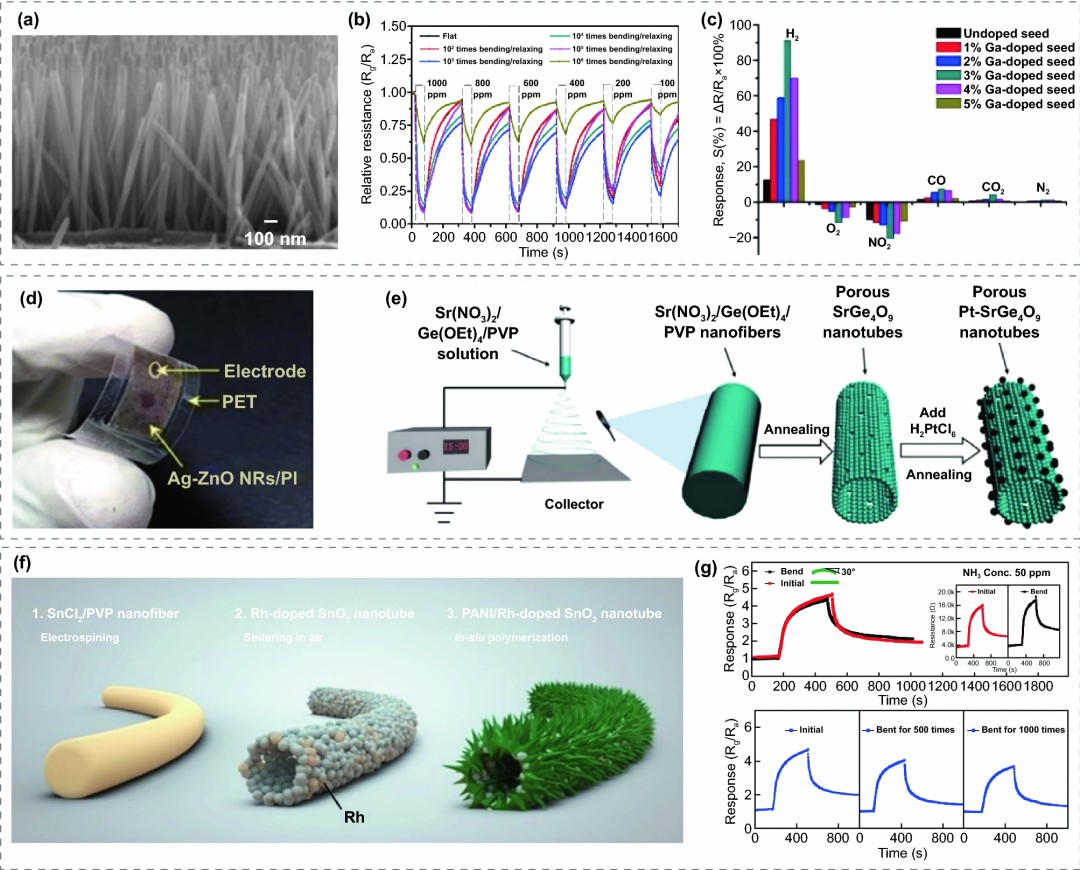

Fig 3 MOS FRT Gas Sensor Modified by Precious Metal Nanoparticles

3.2 Organic polymer-modified MOS FRT gas sensor

Organic conductive polymer gas sensors have the advantages of adjustable electrical properties, simple synthesis, stability, flexibility, excellent environmental stability, and RT operation.

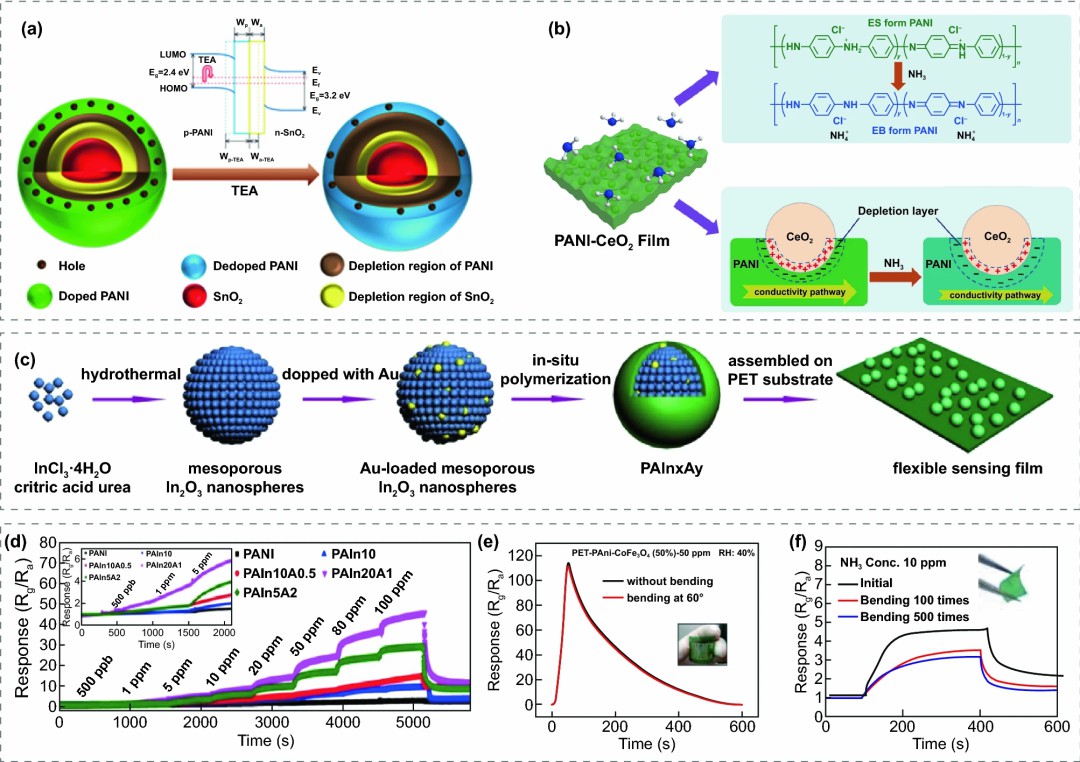

Fig 4 Organic polymer-modified MOS FRT gas sensor

3.3 Carbon based material modified MOS FRT gas sensor

In carbon-based materials modified MOS, the main role of MOS is to detect target gas molecules, and carbon-based materials can be used as huge receptors for injected electrons due to their high conductivity, large surface area, and rich adsorption sites.

Fig 5 Carbon-based material modified MOS FRT gas sensor

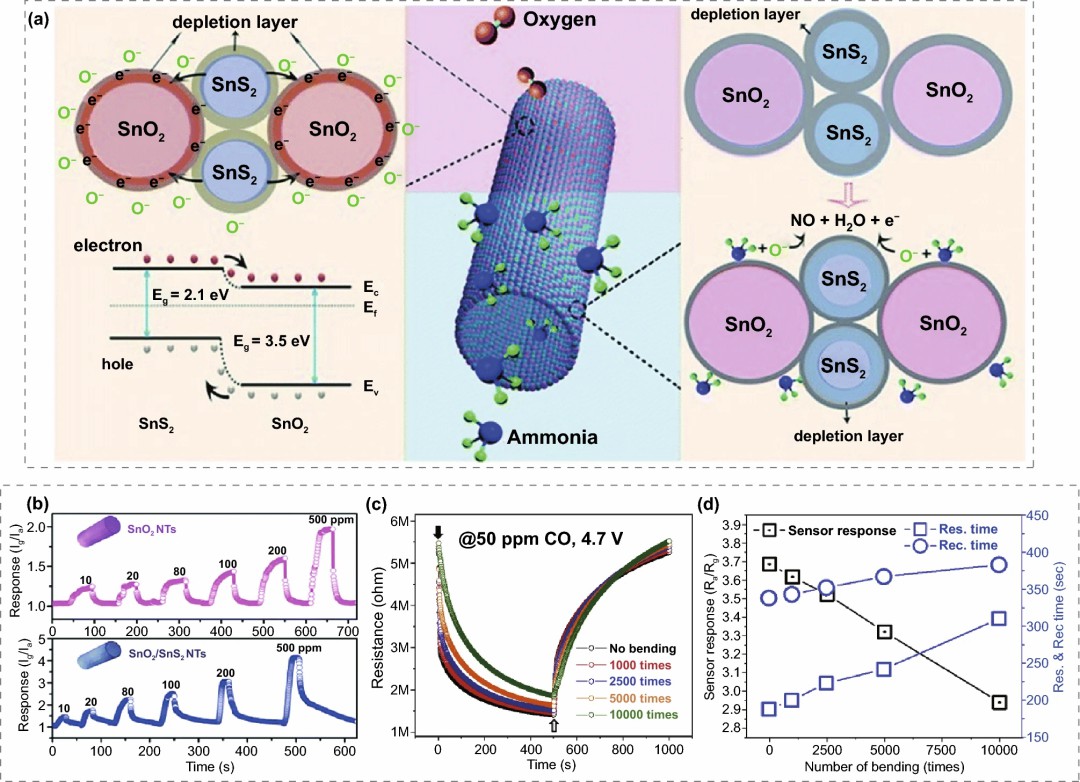

3.4 MOS FRT gas sensor modified by transition metal sulfide

It is caused by their narrow band gap, the large surface area provided by sheet nanostructures, and unique surface and quantum effects. In addition, TMDCs have a layered structure, and the van der Waals force between adjacent layers is weak, which is conducive to gas adsorption. Due to their unique electrical characteristics, TMDCs can operate at lower operating temperatures, reducing overall power consumption and eliminating the need for external heating. It also has excellent inherent conductivity, thermal stability, and oxidation stability.

Fig 6 MOS FRT gas sensor modified by transition metal sulfide

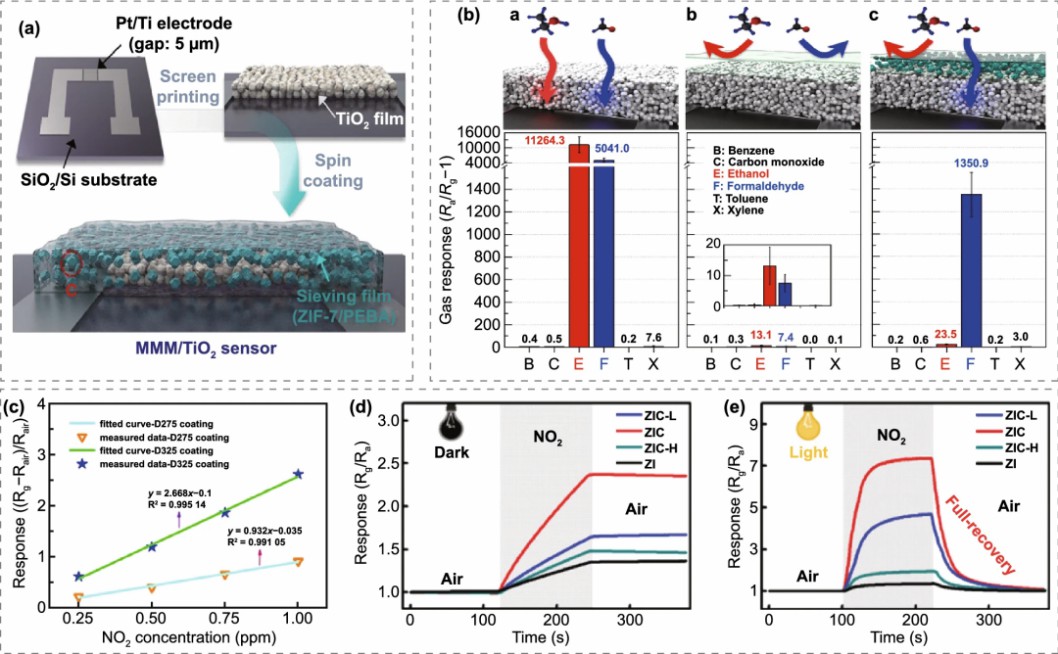

3.5 Light illumination MOS FRT gas sensor

Lighting is also an excellent strategy to enhance the gas sensing characteristics, reduce the operating temperature of MOS gas sensors, and provide a unique way to achieve FRT MOS gas sensors.

Fig 7 Light illumination MOS FRT gas sensor

4. Conclusion

In this review, the latest development of FRT MOS gas sensors is systematically analyzed and summarized. Focusing on the critical review of FRT gas sensors, the focus is on the mixture of original MOS and MOS modified with nanostructured precious metals, organic polymers, carbon-based structures, and transition metal sulfides (TMDC). In addition, the FRT gas sensor based on light MOS is summarized. The strategy of realizing FRT gas sensors is discussed from the point of view of material design, alternate activation, and mechanism explanation. The various types of sensors discussed in this article show that excellent mechanical flexible gas sensors are the appropriate combination of stable contact with flexible substrates (polymer substrates, textiles, paper-based substrates, etc.), device structures, and substrates and sensing materials. At the same time, a high-performance RT gas sensor is a reasonable combination of morphological nanostructures, hybrid materials, and synergistic interface effects. This review has considerable reference value for the design, manufacture, and development of new FRT MOS gas sensors.

Reprinted from the blog of Science Network of Nano Express

Original link: doi.org/10.1007/s40820-022-00956-9