Copyright © 2022 Foshan MBRT Nanofiberlabs Technology Co., Ltd All rights reserved.Site Map

Basic Structure of Coaxial Electrospinning Device

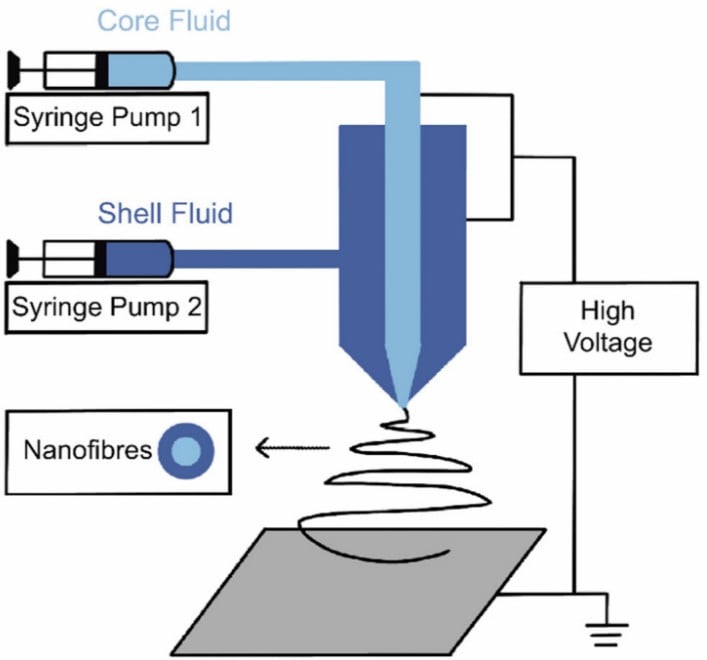

Coaxial electrospinning first appeared in 2002, which is developed from the standard single-axis electrospinning technology. The coaxial electrospinning device (Fig. 1) consists of the following components: a high-voltage power supply, an injection pump, a spinneret, and a collector. The structure of a pair of capillaries coaxially placed in the spinneret is connected to two independent polymer solution storage cavities for the core layer and shell layer respectively. Generally, the core liquid is pulled by the shell liquid to form a composite electrospinning jet, and then the core-sheath fiber is formed under the external thrust of the electric field. For the modified coaxial electrospun nanofibers, the organic solvent is generally used as a sheath solution, while the core solution is polymer solution.

Fig. 1 Schematic Diagram of Coaxial Electrospinning Device

For coaxial electrospinning, since two solutions are used for each core layer and sheath layer, additional considerations such as viscosity, miscibility, conductivity, relative humidity, and feed rate ratio between the core and sheath solutions are crucial for the successful preparation of core-sheath fibers. Natural polymers, including proteins (such as corn gluten, gelatin, and silk) and polysaccharides (such as chitosan, cellulose, and sodium alginate), are widely used as drug delivery materials due to their good biocompatibility.

Selection of core material: generally, the core layer shall be made of materials with relatively good mechanical properties. PVA is usually used as a core material because of its good fiber-forming performance, thermal stability, chemical resistance, and low cost.

Selection of shell materials: generally, materials with good biocompatibility are selected. Hydrophilic biopolymers, such as polyvinyl alcohol (PVA), polyethylene oxide (PEO), and polyvinyl pyrrolidone (PVP), are commonly used. When the viscosity of the shell solution is appropriately higher than that of the core layer, it is conducive to the formation of the composite Taylor cone; The shell solution has high conductivity, which is conducive to the formation of the shell core structure.

Methods to improve the success rate of coaxial electrospinning experiment

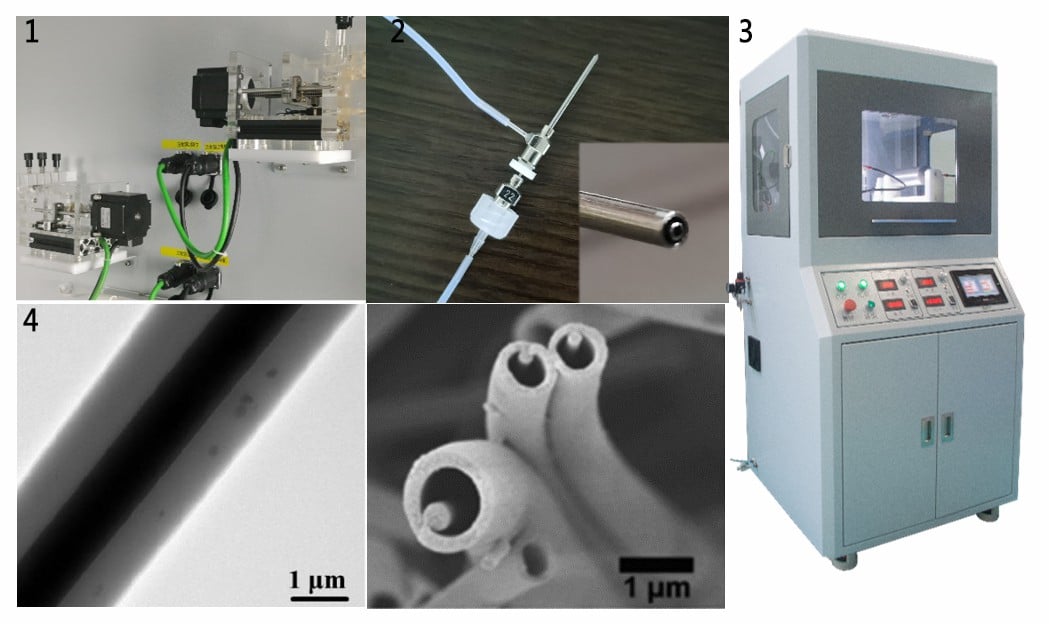

General electrospinning equipment includes a high-voltage power supply, a collection device, a syringe pump, and a syringe, Two fluid syringes and coaxial needles are required for coaxial electrospinning experiments. During the experimental operation, the inner and outer solutions should be placed at the same voltage. Therefore, before the coaxial experiment, separate process experiments can be carried out for the two solutions to determine the different spinning solution propulsion speeds under the same voltage. Generally, the flow rate of the shell solution is higher than that of the core solution. If the flow rate of the core spinning solution is too high, the shell spinning solution cannot wrap the core solution well, and the shell core structure is not perfect. However, if the flow rate of the shell spinning solution is too large, the core solution will be spun separately, and it is difficult to form a coaxial structure.

Different from the traditional electrospinning device, the coaxial electrospinning device requires two syringes that can set the flow rate separately. The Multifunctional Electrospinning Machine E06 has the function of coaxial electrostatic spinning, and has the following characteristics:

(1) Two injection pumps with injection speed control function;

(2) Each module of color touchscreen control equipment operates;

(3) Multiple collection device modules and single-needle or multi-needle nozzles;

(4) It can control the temperature and humidity parameters of the experimental environment and record the experimental parameters.

Fig. 2 (1) Syringe pump with independent flow control; (2) Coaxial needle; (3) Multifunctional Electrospinning Machine E06 ; (4) Microstructure of coaxial fiber

Study on the Application of Coaxial Structural Fiber

(1) Biomedical Applications

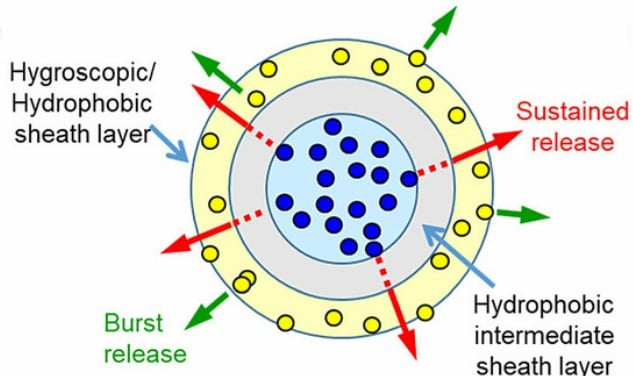

Because the structure of electrospun nanofibers is similar to that of natural extracellular matrix (ECM), the application prospect of electrospun nanofibers in biomedicine has been widely concerned. In addition to the characteristics of traditional electrospinning, coaxial electrospinning also provides other important characteristics related to biomedical applications. The complementary performance combination of the two different materials provides unique functions. Biomaterials such as gelatin and collagen have biocompatibility. Synthetic polymers such as PCL, PLA, and PLLA can be used as the core-sheath layer to increase mechanical strength. These nanofibers made of composite materials can be used to embed drug molecules or growth factors, making them have specific functionality, and can be used in drug release, wound dressing, tissue engineering repair, and other fields.

Fig.3 Double drug delivery application of fiber prepared by three-tier coaxial technology

(2) Application in the energy field

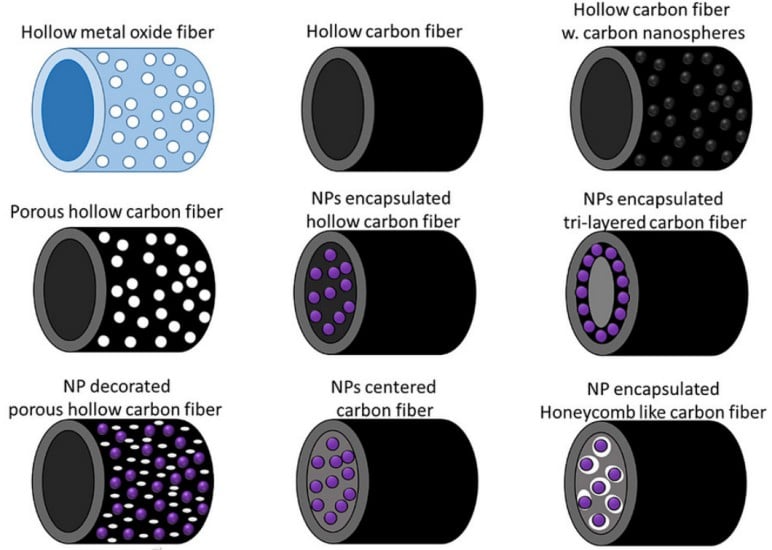

Another area of concern for coaxial electrospinning is the energy field. In many energy-related applications, because of the high demand for rechargeable lithium-ion batteries, the development of advanced electrodes for rechargeable lithium-ion batteries is a hot research direction at present. Coaxial electrospinning can create and customize hollow and porous fiber membranes made of various metal oxides and carbon materials, which leads to more and more academic and industrial research on this subject.

Fig.4 Coaxial optical fiber useful for energy field

(3) Functional textile and environmental applications

In addition to biomedicine and energy fields, some application achievements using core sheath fibers have also been developed for other application fields (such as textiles and environment). In textiles, especially functional textiles such as protective clothing and sportswear, adding nanofibers can obtain special functions, such as enhanced mechanical properties, waterproof and self-cleaning properties. Weathering resistance with good air permeability can be obtained from micro/nano porous electrospun membranes. In addition to protective clothing, coaxial electrospun fiber textiles are also used for a variety of other purposes, such as filters, water collectors, separators and self repairing surfaces. Filtration is one of the most easily realized applications using electrospinning, with a wide variety of materials (including carbon materials) and easy control of pore size and fiber morphology.

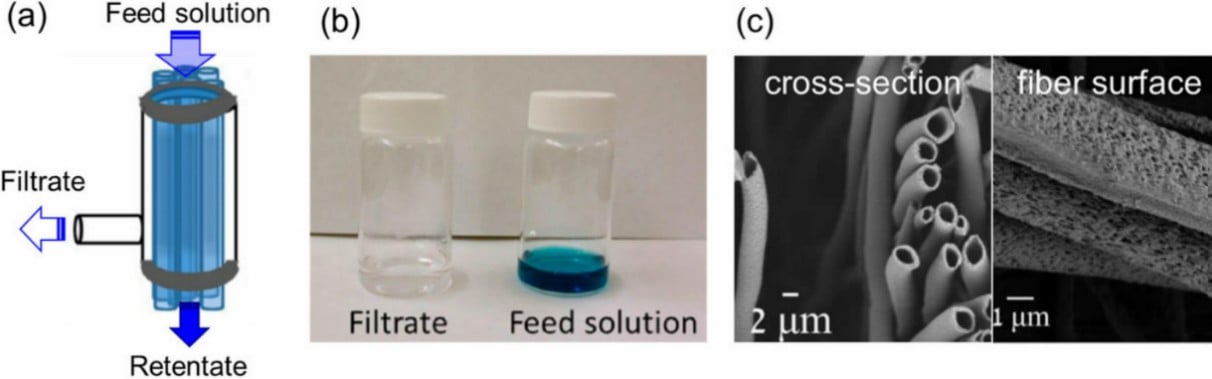

Fig. 5 Water filtration: (a) Filter module configuration. (b) Color difference between filtrate and feed solution. (c) SEM image of PSU hollow fiber

(4) Sensor Applications

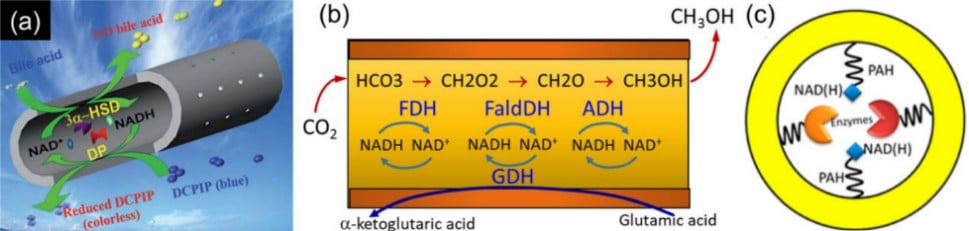

In addition, due to its unique advantages, semiconductor metal oxides have become a unique material for developing sensitive sensors. Coaxial electrospinning can provide hollow metal oxide fibers, which can further increase the surface area to improve sensitivity. Electrospinning is one of the methods for immobilizing enzymes on nanofiber membranes. In particular, bionic cells limited by multiple enzymes and coenzymes can simulate multi-stage biosynthesis of biological cells. Using coaxial electrospinning, enzymes can be immobilized into hollow fibers, which provides a promising solution for biocatalysts.

Fig. 6 Schematic diagram of hollow nanofibers containing enzymes: (a) Multi enzyme artificial cells involving 3a-HSD, DP and NAD (H) for bile acid determination. (b) In situ regeneration of hollow nanofiber multi enzyme system 2 and NADH for methanol synthesis from CO; (c) Fiber configuration of nanostructure enzyme cofactor enzyme catalyst

Obviously, these studies have the possibility of further commercialization. Although coaxial electrospinning technology is considered as a very promising method for preparing multi-functional materials, it lacks large-scale production capacity and has not yet developed core sheath fibers for special fields.

reference:

[1] Li J, Liu Y, Abdelhakim H E. Drug Delivery Applications of Coaxial Electrospun Nanofibres in Cancer Therapy[J]. Molecules, 2022, 27(6): 1803. doi.org/10.3390/molecules27061803

[2] Sang Qingqing Study on preparation of pH sensitive gelatin/PLCL double drug loaded fiber scaffold by coaxial electrospinning [D]. Donghua University, 2018

[3] Han D, Steckl A J. Coaxial electrospinning formation of complex polymer fibers and their applications[J]. ChemPlusChem, 2019, 84(10): 1453-1497. https://doi.org/10.1002/cplu.201900281

[4] Multifunctional Electrospinning Machine E06