Copyright © 2022 Foshan MBRT Nanofiberlabs Technology Co., Ltd All rights reserved.Site Map

Topic: PCL (polycaprolactone) electrospinning process manual

Contents

1. Properties of PCL materials

2. Application of electrospun PCL in biomedicine

3. Experimental parameters of electrospun PCL

4. Common spinning problems and Solutions

1. Properties of PCL materials

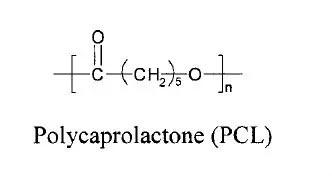

Polycaprolactone (PCL) is also called poly ε- Caprolactone, an organic polymer with the chemical formula (C6H10O2) n, is obtained by ε- Caprolactone monomers are ring opening polymerized under the catalysis of metal anion complex catalyst. Different molecular weights can be obtained by controlling the polymerization conditions. Its appearance is opaque white solid powder, non-toxic, with certain rigidity and strength, showing typical resin characteristics, insoluble in water, easily soluble in toluene, tetrahydrofuran, ethyl acetate, dichloromethane and other polar organic solvents.

PCL has good biocompatibility, good organic polymer compatibility, and good biodegradability. It can be used as a support material for cell growth. It can be compatible with a variety of conventional plastics and can be completely degraded in 6-12 months under natural environment. In addition, PCL has five non-polar methylene groups and one polar ester group on the structural repeating unit, so it has good flexibility and processability, while the product has shape memory. It is widely used in the production and processing fields such as drug carriers, degradable plastics and nanofiber spinning.

2. Application of electrospun PCL

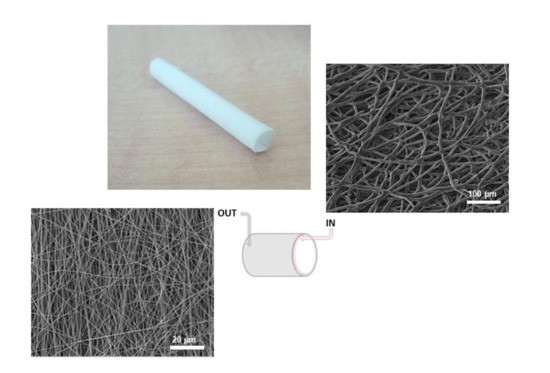

(1) Biological scaffolds: tissue engineering technology mainly focuses on the extracellular matrix that supports cell growth, proliferation, differentiation and function. In our body, the extracellular matrix (ECM) is similar to a scaffold, composed of 3D nanofiber structures made of collagen and other biopolymers. Therefore, if made of nanofibers, 3D scaffolds can provide a bionic structure similar to ECM. The nanoscale characteristics of nanofiber scaffolds have a high surface area to volume ratio, which enhances cell adhesion and cell migration, and helps to provide nutrition to cells more effectively. PCL is a linear hydrophobic synthetic polymer with high mechanical strength and good biocompatibility. Electrospun PCL nanofiber scaffolds simulate ECM in living tissue structurally, but they are hydrophobic and have no cellular activity. The combination of gelatin and PCL can effectively improve the cell adhesion and proliferation characteristics, and it is a stable and flexible composite scaffold. For clinical application, advanced surface modification and preclinical experiments of biological tubular scaffolds are necessary.

Figure 1: electrospun PCL based vascular graft

DOI:doi.org/10.3390/nano11030751

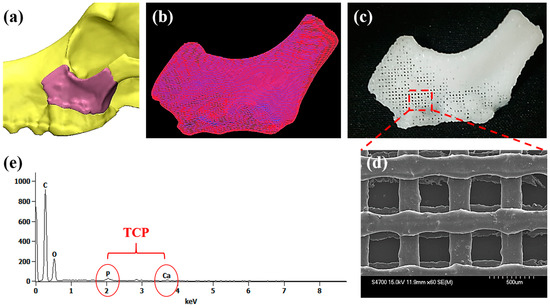

(2) Tissue regeneration: tissue regeneration is a rapidly developing and intersecting field in life science, biology, material science and engineering. Many studies have shown that electrospinning has great potential in tissue regeneration. Nerve tissue regeneration, heart tissue regeneration, bone tissue regeneration, vascular tissue regeneration, skin tissue regeneration and other tissue regeneration have been widely and deeply studied in the academic community. Materials used to construct tissue engineering scaffolds should have biocompatibility and biodegradability, as well as mechanical properties that can be supported in vivo. Scaffolds for tissue engineering are usually made of natural and synthetic polymeric materials. It has excellent biocompatibility, non-toxic, excellent mechanical properties, and can be hydrolyzed or degraded by enzymes in vivo, making it an ideal polymer for scaffolds. PCL, polylactide co glycolide and polylactic acid (PLA) are typical synthetic polymer materials.

Figure 2: PCL / tricalcium phosphate and 3D printing technology were applied to induce osteogenesis of adipose stem cells and bone marrow stem cells in the canine maxillary defect model

DOI: doi.org/10.3390/polym9090450

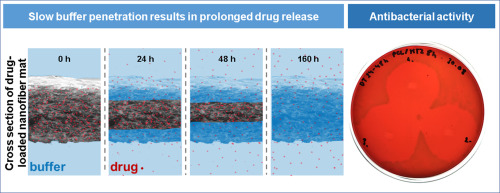

(3) Drug release: electrospinning technology can design and manufacture new drug delivery systems to promote local antibacterial treatment. Electrospun nanofiber pads loaded with antibiotics need certain properties to ensure antibacterial effect and prolong drug delivery time in local treatment of infectious diseases. Since the drug release from the electrospun hydrophilic polymer pad is usually immediate, the hydrophobic polymer pad is preferred. The hydrophobicity and thickness of PCL nanofiber mat are the key characteristics of prolonging the release of hydrophilic drugs. It has chemical stability, biocompatibility, biodegradability, affordable price, and is easy to electrospun. It often acts on targeted drug delivery and the like.

Figure 3: effect of structural characteristics of PCL nanofiber pad on hydrophilic drug release and antimicrobial activity against periodontal pathogens

DOI:doi.org/10.1016/j.ejps.2018.07.024

3. Experimental data of electrospun PCL

Experiment purpose: to test the functional system and process parameters of the equipment

Experiment 1

Process: electrospun PCL oriented fiber

Instrument: lepton nano electrospinning machine E05

PCL material: molecular weight: 80000, concentration: 12%, solvent ratio = DMF: dichloromethane = 1:2

Voltage: 18kV, - 3KV

Liquid supply: 0.8ml/h needle: 22G 10ml syringe

Speed: 3000rpm, linear speed: 750m / min

Spinning distance: 15cm

Temperature: 34 ℃

Humidity: 52%

Experiment 2

Process: melt direct writing grid support

Instrument: lepton nano near field direct writing device M08

Collection method: plane collection

Material: PCL, melting point 59 ~ 64 ℃

Spinning distance: 3mm ~ 5mm

Voltage: 3KV ~ 5kV

Air pressure: 5kpa ~ 20KPa

Speed: 30 ~ 80mm / S

Temperature: 120 ~ 130 ℃ for 10min

Remarks: 1. PCL can only be spun for 0.5 ~ 1 day in summer due to the humidity and heat of the air and its variability; 2. The fiber with the speed of 30mm / s and below will be subject to axial bending.

4. Common spinning problems and Solutions

(1) PCL granular materials need to be dried at 50 ℃ in advance for the first use, which will be accompanied by a little degree of melting without influence.

(2) A large number of bead like particles appear, which may be because the solution concentration is too small, and the concentration can be increased.