Copyright © 2022 Foshan MBRT Nanofiberlabs Technology Co., Ltd All rights reserved.Site Map

Contents

1. The properties of PVDF material

2. Application of electrospinning PVDF

3. Electrospinning PVDF process

4. Common spinning problems and solutions

1. The properties of PVDF material

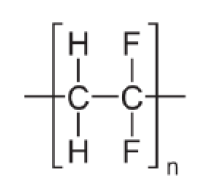

Polyvinylidene fluoride, or polyvinylidene difluoride, (PVDF) is a highly non-reactive thermoplastic fluoropolymer produced by the polymerization of vinylidene difluoride. PVDF is a specialty plastic used in applications requiring the highest purity, as well as resistance to solvents, acids and bases. Compared to other fluoropolymers, like polytetrafluoroethylene (Teflon), PVDF has a low density (1.78 g/cm3).

PVDF has a glass transition temperature (Tg) of about −35 °C and is typically 50–60% crystalline. To give the material its piezoelectric properties, it is mechanically stretched to orient the molecular chains and then poled under tension. It has excellent mechanical properties, chemical stability, biocompatibility, hydrophobicity, high dielectric strength and resistance to ultraviolet radiation degradation. Only soluble in N,N dimethylformamide (DMF), N,N dimethylacetamide (DMAc), dimethyl sulfoxide (DMSO), tetrahydrofuran (THF) and N-methylpyrrolidone (NMP), etc.

Figure 1

2.Application of electrospinning PVDF

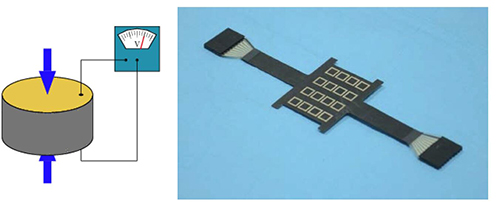

(1) Piezoelectric film: PVDF generally exists as a non-polar α crystal phase and does not have piezoelectric properties. Through methods such as high-voltage polarization, β-crystalline PVDF can be obtained, which has good piezoelectric properties. Compared with traditional piezoelectric materials, PVDF has the characteristics of wide frequency response, high sensitivity of power-to-electricity conversion, high strength, and has the advantages of light weight, good flexibility, and impact resistance. The PVDF fiber membrane prepared by the electrospinning method has the advantages of simple operation, convenience and low cost, and the prepared PVDF fiber membrane is soft and light, especially it has good air permeability and is an ideal choice for wearable products . At the same time, the electrospinning process integrates polarization and stretching, which is the advantage of using electrospinning to prepare β-crystalline PVDF piezoelectric films.

Figure 2 Application of electrospinning piezoelectric film

(2) Waterproof and moisture-permeable membrane: Water-proof and breathable (moisture-permeable) materials are also called breathable materials (breathable fabrics, breathable paper, etc.), which can prevent liquid water from passing or permeating, and at the same time can permeate gas (or water vapor) )s material. The static contact angle of PVDF is much greater than 90°, which is a strong hydrophobic substance, and the PVDF fiber membrane prepared by electrospinning has high porosity, which is much better than traditional coated membranes. The prepared waterproof and moisture-permeable nanofiber membrane can be widely used in racing suits, golf wear, waterproof clothing, hiking shoes, shower curtains, tablecloths, raincoats, sailing suits, fishing pants, windbreakers, cold jackets, ski suits, ski gloves, mountaineering Clothing, hunting clothing, surfing clothing, jackets, lighting accessories, mobile phone waterproof accessories and other fields.

Figure 3 Application of electrospinning waterproof and moisture-permeable membrane

(3) Waterproof sound-permeable membrane: Nowadays, with the continuous development of electronic products, the waterproof performance of electronic products has also been continuously improved, and the waterproof sound-permeable membrane has also been upgraded from IP54 to IP68. PVDF nanofiber membrane has excellent hydrophobicity and air permeability. It is used in all kinds of waterproof mobile phones, waterproof cameras and waterproof electronic products. It is dustproof, waterproof and breathable without affecting its sound quality.

Figure 4 Application of electrospinning waterproof sound-permeable membrane

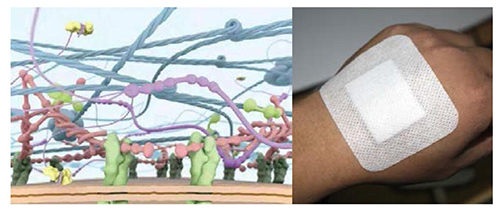

(4) Medical dressing film: PVDF has good biocompatibility and physicochemical properties. The nanofiber scaffold structure formed by PVDF is similar to the extracellular matrix, which is conducive to cell adhesion and growth, and can promote cell contact, penetration, and cell retention. The stability of the structure allows cells to grow directionally along the fibers. Its hydrophobic properties can prevent moisture from volatilizing from the wound, high porosity and good tensile properties can maintain air permeability and flexibility.

Figure 5 Application of electrospinning medical dressing film

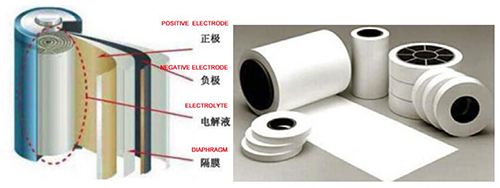

(5) Lithium-ion battery separators: PVDF and other fluorine-based polymers have always received great attention because of their good chemical stability and good affinity for electrolytes. The battery separator is an indispensable part of the battery, which is used to separate the positive and negative active materials of the battery to avoid short circuit of the battery. The diaphragm has two important functions. In addition to avoiding the direct passage of any electron flow between the positive and negative electrodes, it also requires the resistance of the ion flow to pass as small as possible. Therefore, the choice of porous non-conductor PVDF nanofiber membrane as the diaphragm material can best meet these two opposing requirements.

Figure 6 Application of electrospinning lithium battery separator

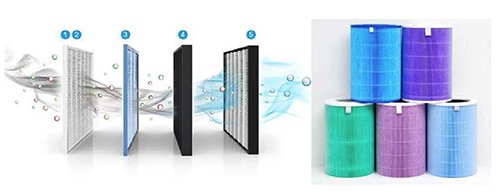

(6) High efficiency and low resistance air/water filter membrane

The fiber air filter material is constructed by many complicated arrangement of fibers. The traditional fiber air filter material has a larger pore size. Even the melt blown filter material with better filtering performance has a pore size of ten to tens of microns, which filters fine particles. The effect is not good. PVDF nanofiber membrane has the advantages of small pore size, high porosity, large specific surface area, and good adsorption performance. It is very suitable for air/water filtration materials, and the nanofiber membrane is modified by surface coating and blending. Effectively improve the hydrophilicity, retention rate and pollution resistance of the membrane.

Figure 7 Application of electrospinning high efficiency low resistance filter membrane

3. Electrospinning PVDF process

3.1 Main materials and instruments

(1) Spinning material: PVDF particles or powder, molecular weight 100,000-1,000,000; DMF (or DMAc) solvent, analytically pure.

(2) Experimental equipment: 50mL conical flask, magnetic stirrer, water bath, electronic balance, E05 electrostatic spinning machine.

3.2 Spinning solution configuration

Use an electronic balance to weigh a certain quality of solvent DMF into an Erlenmeyer flask, add a magnetic stirrer, and stir in a water bath; then weigh a certain quality of PVDF and slowly add it to the stirring Erlenmeyer flask; cap the bottle tightly to prevent The water vapor enters the Erlenmeyer flask; set the water bath temperature to 60°C, continue to stir and dissolve for 4 hours, until the solution is clear and transparent, and a PVDF spinning solution with a certain mass concentration can be obtained.

The mass concentration of common PVDF spinning solution is 10% -22%; the solvent system is DMF (DMAc), DMF/AC (7:3), DMF/THF (7:3).

3.3 Spinning process and parameters

Pump the above PVDF spinning solution into a 20mL syringe, fix the syringe to the injection pump of the spinning machine, install a 20G (1/2 inch, flat mouth) stainless steel needle, connect the needle to the positive pole of the high-voltage power supply, and connect the receiving roller to the negative pole of the high-voltage power supply. The receiving substrate is pasted on the roller; the syringe pump specifications are set to 20mL, the liquid supply speed is 2mL/h, the roller speed is 300 rpm, the sliding table stroke is 20cm, the spinning distance is 15cm, and the spinning voltage is positive 15kV and negative 5kV. The temperature is 35℃, the humidity is 40%, and the timing is 120min. Finally, close the equipment door and open the exhaust air.

Commonly used electrospinning receiving substrate: aluminum foil paper, release paper, non-woven fabric, mesh cloth, etc.

4. Common spinning problems and solutions

(1) Under the scanning electron microscope, there are many beads on the fiber: generally the PVDF concentration in the spinning solution is too low, resulting in insufficient spinning solution viscosity. It is recommended to continue to increase the PVDF concentration. Under normal circumstances, as the concentration of the spinning solution increases, the spun product will change from micro-nano particles, beaded fibers, uniform fibers to coarse fibers. In addition, the molecular weight of PVDF is too small, and PVDF molecules are entangled in the solution. Insufficient knots will also cause the fiber to produce beads. It is not recommended to use PVDF raw materials with too low molecular weight.

(2) During the spinning process, the needle tip hangs and floats: Generally, the spinning environment humidity is too high, the spinning jet absorbs moisture in the air and solidifies in advance and the charge on the fiber is neutralized, resulting in a decrease in fiber charge and fiber stretching The performance is weakened, the electric field force is weakened, and it is not enough to adsorb to the receiving electrode. You can try dehumidifier dehumidification or heating dehumidification.

(3) Gelation occurs during the preservation of the spinning solution: PVDF spinning solution is easy to absorb moisture in the air and solidify, so it needs to be stored in a dry and airtight condition. It is recommended to use it now or keep it sealed for 3 days.