Copyright © 2022 Foshan MBRT Nanofiberlabs Technology Co., Ltd All rights reserved.Site Map

Contents

1. Properties of PLA materials

2. Application of electrospinning PLA

3. Electrospinning PLA process

4. Common spinning problems and solutions

1.Properties of PLA materials

Poly (lactic acid), also known as poly (lactide), is a kind of new biodegradable material, which is a polyester polymer obtained from the polymerization of lactic acid as the main raw material. Polylactic acid (H-[OCHCH3CO] N-OH) has the characteristics of good thermal stability, processing temperature of 170 ~ 230℃, has good solvent resistance, can be processed in a variety of ways, such as extrusion, spinning, biaxial stretching, injection blow molding. In addition to biodegradability, products made from polylactic acid have good biocompatibility, glossiness, transparency, feel and heat resistance. Polylactic acid can be dissolved in some organic solvents, including chloroform, acetone, ethyl acetate, dimethylformamide, ethanol, dichloromethane, trichloromethane.

2.Application of electrospinning PLA

(1)Drug sustained release:Because PLA is soluble in solvents easily as a drug carrier, the product of polylactic acid drug carrier has no side effect on organism and environment during hydrolysis. Therefore, polylactic acid as a drug release material can slow down the release rate of drugs, so as to extend the time for drug control of disease to a certain extent, and better maintain the efficacy of drugs, which can be used in dressings, drug coats, etc.

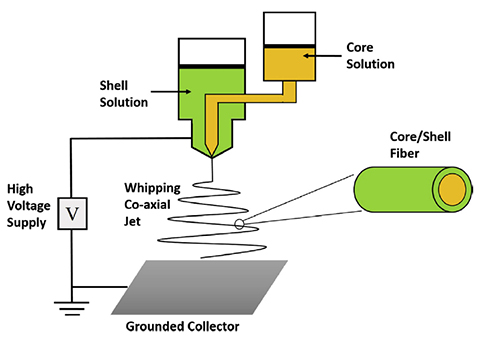

In the manufacturing of scaffold materials for drug slow release delivery, there is material mixing spinning method, multi-layer structure printing composite method, core-shell technology preparation method, adsorption method, etc. Among them, the core-shell technology is considered to be a more promising method. With polylactic acid material as the shell and drug active ingredient as the nuclear layer, through the slow dissolution of polylactic acid material in the body, the function of slow release of drugs is realized. More technical information can be obtained by adding the WeChat ID "Nano Tool Man" at the end of this article.

Figure 1 Principle model diagram of core-shell structure preparation

(2)Biological patch:PLA has good biocompatibility and degradation performance in vivo. The biological patch with PLA as the main material has a nanofiber scaffold structure similar to the extracellular matrix, which is conducive to cell adhesion and growth, and can promote cell contact, penetration, maintain the stability of cell structure, and make cells grow along the fiber orientation

Figure 2 Biological patch

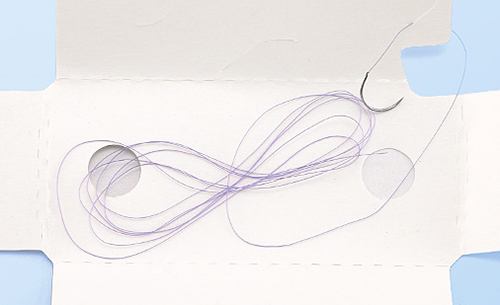

(3)Surgical sutures:PLA has good biocompatibility and degradability in vivo. PLA is prepared into Surgical sutures by electrospinning, which does not need to be removed twice after surgery, and has good compatibility with the body and can be self-degradable.

Figure 3 Surgical sutures

(4)garment fabric:Electrospinning can process PLA into yarn, nonwovens, etc., which has flamability and biocompatibility. The finished fabric has silky luster and feel, excellent drapability and smoothness. It does not stimulate skin, is healthy for human body, and is comfortable to wear, especially suitable for underwear and sportswear. At the same time, as an environmentally friendly degradable material, PLA has great potential for future application in the field of clothing fabrics.

Figure 4 Clothing fabric application process

3.Electrospinning PLA process

3.1 Main materials and instruments:

(1)Spinning material: PLA granule or powder, molecular weight 60,000-500,000; DMF (or E dichloromethane) solvent, analytical pure.

(2)Experimental Instruments: 50mL conical flask, magnetic stirrer, water bath pot, electronic balance, E05 electrospinning machine /MF04-002 mass production equipment.

3.2 Preparation of spinning fluid

Use an electronic balance to weigh a certain mass of solvent DMF in a conical flask, add a magnetic agitator, and stir in a water bath. Then weigh PLA of a certain quality and slowly add it into the conical flask. Close the cap tightly to prevent water vapor from entering the conical bottle. The water bath temperature was set at 60℃, and the solution was continuously stirred and dissolved for 4h until it was clear and transparent. PLA spinning solution with a certain mass concentration was obtained.

The mass concentration of common PLA spinning solution is 10%-15%. The solvent system includes chloroform, acetone, ethyl acetate, dimethylformamide, ethanol, dichloromethane, trichloromethane and so on.

3.3 Spinning process and parameters

The PLA spinning liquid was pumped into a 20mL syringe, the syringe was fixed to the syringe pump of the spinning machine, and a 20G (1/2inch, flat mouth) stainless steel needle and an appropriate air spinning nozzle were installed. The needle was connected to the positive pole of the high voltage power supply, the receiving roller was connected to the negative pole of the high voltage power supply, and the receiving base material was affixed to the roller. The syring-pump specification was set as 20mL, the liquid supply speed was 1~5mL/h, the nozzle pressure was 0.01~ 0.02MPa, the roller speed was 300 RPM, the slide stroke was 20cm, the spinning voltage was positive 15kV and negative 5kV, the temperature was 35℃, the humidity was 40%, the timing was 120min, and finally the device door was closed and the exhaust air was opened.

Commonly used receiving substrate: aluminum foil paper, release paper, non-woven cloth, screen cloth, etc.

4.Common spinning problems and solutions

(1)Gelation occurs during the preservation of the spinning fluid:Some PLA spinning liquid has certain requirements for storage temperature, so it should be stored in a dry and airtight condition with a certain temperature range. It is recommended to use it on the spot or to keep it sealed within 2 days.

(2)Strips of gel appear at the tip of the needle during spinning,:When PLA spinning liquid is below a certain temperature, the viscosity will gradually increase, and gel strips are easy to appear at the tip, which will grow and lengthen continuously until the spinning drops off. Alternatively, the phenomenon can be caused by excessive humidity in the air source. Therefore, in the process of spinning, it is necessary to ensure that the ambient temperature of the spinning liquid is within a certain temperature range, and the humidity of the air source should not be too high, so as to avoid the problem that the viscosity of the solution changes or the contact with the wet gas at the tip of the needle will not be able to continue spinning normally.

(3)The fiber diameter distribution is large and the fiber diameter is thick:Generally, the PLA concentration in the spinning liquid is too high, so it is recommended to continue to reduce the PLA concentration. In addition, the PLA molecular weight is too high, the PLA molecules are too entangled in the solution, the viscosity is improved, and the drafting force is insufficient, which will also lead to the fiber diameter coarsening.