-Biological cleanliness;

-High spinning output;

-Various electrospinning spinnerets and collectors;

-Easily prepare two-component products;

-Good uniformity of nanofiber membrane;

-Friendly man-machine interface;

-Controllable temperature and humidity.

Biomedicine electrospinning equipment introduction

Semi-industrial biomedical electrospinning equipment (MF01-009) is a batch nanofiber production electrospinning equipment developed for the field of biomedicine. All metal parts in the spinning chamber are made of uncoated, corrosion-resistant 316 stainless steel, and all plastic parts are made of corrosion-resistant, high-insulating PTFE material. The spinning chamber can adapt to frequent sterilization and disinfection in the field of biomedicine, is easy to clean and not easy to generate dust, and meet the sterility and cleanliness requirements of the biomedical industry.

The patented array-type multi-needle spinneret assembly optimizes the electric field interference between the multi-needles, resulting in high spinning output and good fiber diameter uniformity. Provide large-diameter roller collectors, cage collectors, tubular scaffold thin-axis collectors, and other types of receiving devices to meet the needs of large-scale preparation of biological dressings, tissue engineering, and vascular stents. It adopts a modular design and has strong expansibility, the functions and production capacity can be customized according to customer needs.

Electrospinning equipment features

(1) Biological cleanliness:The contact parts of the raw materials are made of 316 stainless steel and PTFE, and the spinning is carried out in a closed spinning chamber;

(2) High spinning output: The patented array-type multi-needle spinneret assembly optimizes the electric field interference between the multi-needles, resulting in high spinning output and good fiber diameter uniformity;

(3) Various electrospinning spinnerets and collectors: Freely switch between large-diameter roller collectors, cage collectors and tubular scaffold thin-axis collectors to meet the needs of large-scale preparation of biological dressings, tissue engineering materials, and vascular scaffold;

(4) Easily prepare two-component products: Standard high-power double syringe pump, double-positive high voltage power supply, can spin two different materials at the same time;

(5) Good uniformity of nanofiber membrane: Equipped with a sliding table device that makes the nozzle reciprocating, it has the same nanofiber membrane uniformity as single-needle electrospinning;

(7) Friendly man-machine interface: All operating parameters can be programmed and integrated through the touch screen interface to control, detect and record;

(8) Controllable temperature and humidity: Integrates a temperature and humidity control module, so there is no need to worry about spinning in rainy weather.

Electrospinning machine for biomedicine | |

1. According to customers with biological cleanliness requirements, the cavity can be customized with dust-free and clean S316 stainless steel; 2. All plastic parts are made of corrosion-resistant, high-insulation PTFE material; 3. It can adapt to frequent sterilization and disinfection in the field of biomedicine, is easy to clean and not easy to generate dust, and meets the requirements of sterility and cleanliness in the biomedical industry. |

|

Electrospinning equipment parameter

1 Equipment Specifications: 145*185*198 cm; The maximum power is about 8kw.

2 High voltage power supply:

(1)Positive voltage 0~+50kV, current ≤2mA, including overcurrent and overvoltage protection;

(2) Negative voltage 0~-30kV, current ≤1mA, including overcurrent and overvoltage protection; (3) Contains one set of positive voltages and negative voltages.

3 Electrospinning Liquid supply system:

(1)Equipped with a medical clean injection pump; Applicable syringe specifications: 50, 100ml;(2)The liquid supply speed is 1~400ml/h.

4 Electrospinning nozzle system:

(1) 2 sets of spinning nozzle modules, each with 1*16 needles; the alloy material is used to ensure cleanliness and convenient cleaning;

(2) maximum spinning width is 600mm.

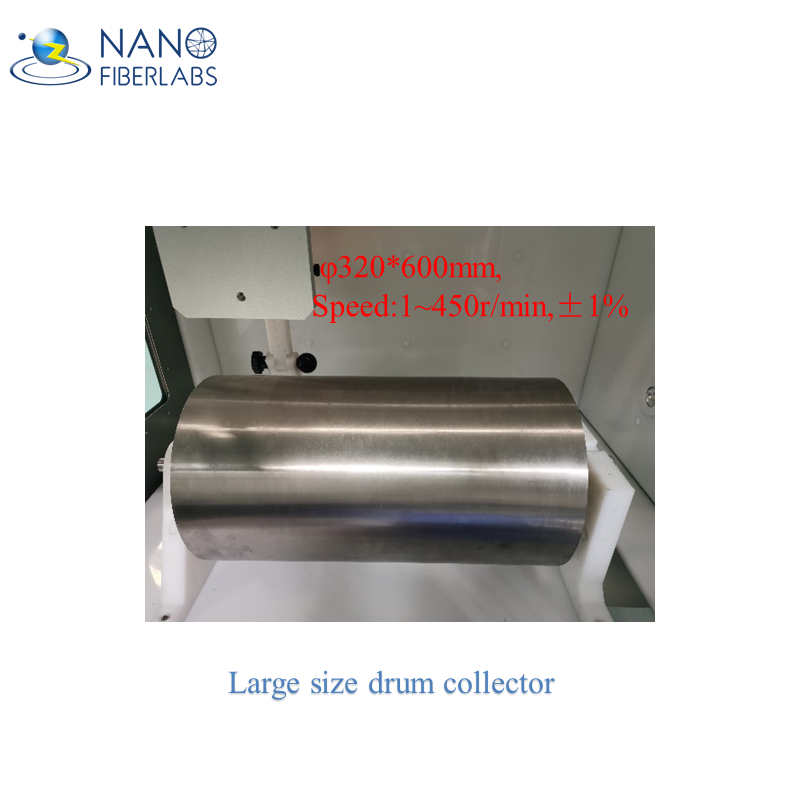

5 Nanofiber collector:

(1)A set of large size drum roller collectors; specification φ320*600mm;speed is 1~450r/min,±1%; (2)The material is made of stainless steel, which meets the requirements of cleanliness.

6 Other collectors:

(1) Parallel electrode collector, adjustable spacing is 0-100mm; oriented fiber can be prepared (1 set);

(2) Cage collector, tubular cage collector, cage outer diameter 80mm, tube diameter 8mm; oriented fiber can be prepared (1 set);

(3) Tubular collector, one set of a tube from φ2~8; can prepare a tube-shaped bracket (1 set);

(4) Drum collector effective width 200mm, diameter ø80mm; drum speed: 100-3000r/min adjustable.

7 Temperature and humidity control system:

(1) The heating plate is built in the cavity to control the temperature, and the temperature control range is adjustable: room temperature~40℃, deviation ±3℃;

(2) The humidity control range is adjustable: indoor 40%RH~room humidity, deviation ±3%;

(3) The exhaust on the top of the equipment, with a maximum air volume of 240m³/h, and the pipeline has a check valve function to prevent backflow of the exhaust air.

8 Control system:

(1)PLC control system: 10in color touch screen, English control interface.

(2)It can control the parameters of the mobile sliding table, the liquid supply parameters, the drum speed, the ambient temperature and humidity in the cavity, and the spinning time, and control the experimental parameters.

(3)10 groups of overall spinning parameters can be set. After setting the time, each parameter can be automatically converted. There is no need to stop the whole process of switching.

(4)The parameters are automatically recorded and saved, which is convenient for comparing test results.The stored process data is imported into the computer for analysis.

Electrospinning application fields:

(1) Medical dressing: Dressing for external wound care;Medical dressing for skin regeneration; Medical dressing with directional drug release function; Skincare mask.

(2) Tissue engineering scaffold: Bone;cartilage scaffold; Tendon tissue scaffold; Nerve scaffold; Vascular scaffold;Urethral scaffold; Heart valve scaffold; Esophageal scaffold.

(3) Controlled drug release: Antibiotics, growth factors; Lipophilic drugs such as ibuprofen, cefazolin, rifampicin, paclitaxel; Hydrophilic drugs tetracycline hydrochloride, etc.

(4) Immobilization of biological enzymes: Phospholipase A1; Acetylcholinesterase; Trypsin; β-galactosidase, laccase.

(5) Biosensor: Glucose, hydrogen peroxide, urea; antibiotic; Hydroquinone, Catechol

(6) Personal protective materials: Antibacterial and antiviral filter material; Antibacterial and antiviral masks; Antibacterial and antiviral protective clothing.

(7) Other: Battery separators, electrode materials, high-efficiency and low-resistance air/water filtration materials, waterproof and moisture-permeable membranes, high-performance catalyst materials, sound-absorbing materials, oil-absorbing materials, high-temperature insulation/warm-keeping materials, national defense industry, etc.