Integrated support for interdisciplinary research, clinical translation and technology services;

Software and hardware systems developed based on bio-3D printing needs,providing rich print path design algorithms, model libraries and manipulation methods;

Enables multi-channel synergistic/synchronized printing of cells, hydrogels, polymers and inorganic materials, etc;

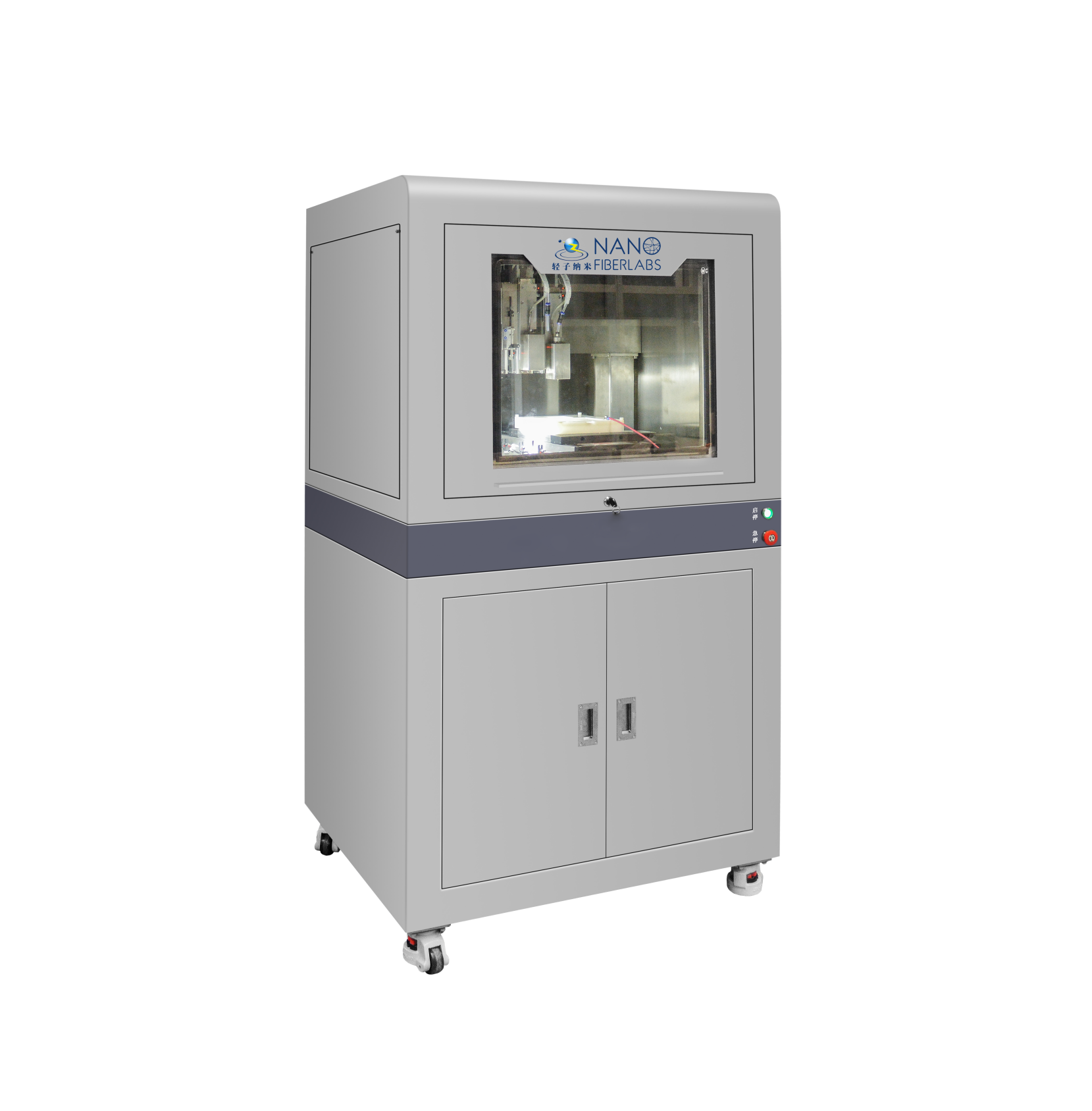

Integrated intelligent ultra-clean control system, fully enclosed high-precision modules to meet the needs of high cleanliness and high-precision printing.

Biomaterials 3D printer is a technology developed for tissue regeneration and repair, which is conducive to the proliferation and differentiation of cells and can quickly promote defective tissue repair and regeneration. The device can prepare scaffolds with a diameter of less than 1 micron, which is conducive to cell attachment and differentiation. And the equipment is equipped with 3 nozzles, which can switch multi-material, melt/solution and multi-process collaborative printing at any time. |

Product features

(1) Three-nozzle system: multi-material, melt/solution and multi-process collaborative switching printing

(2) Optional low temperature printing device

(3) High-precision motion platform

(4) Controllable temperature and humidity

(5) Medical stainless steel inner cavity

(6) Preparation of highly ordered micro-nano fibers

(7) Camera system

(8) Wide range of spinnable materials

Technical parameter

Num | Item | Parameter | |

1 | Spinnable material | Most polymer solutions such as PVA, PCL, TPU, PEO, etc | |

2 | High voltage power supply | 0~50KV | |

3 | Melt nozzle | Heating temperature | Room temperature~300℃ |

| Pneumatic feeding | The minimum pressure of the high precision pressure regulating valve can be adjusted to 0.1Mpa | ||

4 | Precision injection pump | Applicable syringe specifications | 10ul、100ul、1000ul |

| Liquid supply speed | minimum 10ul/h | ||

5 | Nozzle switching system | Printing with multiple nozzles | |

| The print head automatically switches according to the setting | |||

6 | Z axis motion system | stroke | Adjustment range 0-80mm |

| Platform movement accuracy | 5μm | ||

7 | X-Y motion platform | X、Y axis effective stroke:350mm×350mm | |

| Collection speed:0~300mm/s | |||

| Square wave trace collection and custom trace collection | |||

| Motion accuracy ≤1μm | |||

8 | Collection platform | Conductive glass collection | |

| Effective collection area:100mm×100mm | |||

9 | Environmental control | Temperature control: room temperature~50℃ | |

| Humidity control: environmental humidity~90% | |||

10 | Camera system | HD microscope camera | |

| Resolution:1080P | |||

| Magnification 50X~500X adjustable | |||

11 | Needle positioning | Laser positioning: needle position correction; needle height correction; positioning accuracy ≤ 2μm | |

12 | Medical grade printing cavity | The spinning chamber meets the residual cleanliness standard | |

| All stainless steel structure | |||

| 304 stainless steel material | |||

13 | Equipment size | 85cm (L) * 85cm (W) *180cm (H) | |

Application area

The equipment can be used to prepare various organic nanofiber membranes, organic/inorganic hybrid nanofiber membranes and inorganic ceramic nanofiber membranes. The prepared nanofiber membrane has the advantages of small fiber diameter, large specific surface area, small pore size and high porosity. It is widely used in tissue regeneration and repair, such as hernia repair, skin repair, dental model repair, myocardial repair, nerve repair, blood vessel repair, meningeal repair, etc.