-X axis effective range: 850mm

-Collection speed: 0-200mm/s

-Revolving speed: 0~300r/min, accuracy +/- 3%

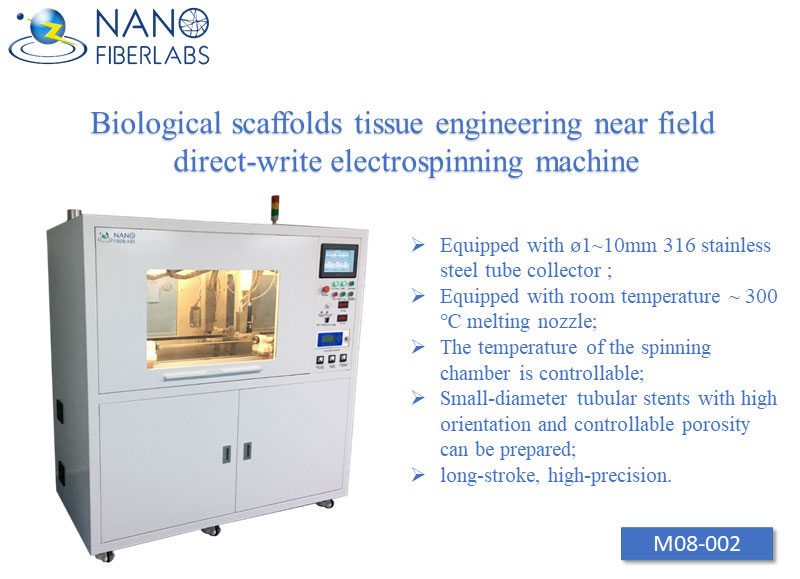

-Equipped with ø1~10mm 316 stainless steel tube collector can print tubular bracket, aspect ratio (L-850mm, p1-10mm);

-Equipped with room temperature ~ 300 ℃ melting nozzle;

-The temperature of the spinning chamber is controllable;

-The fiber diameter is controllable, small-diameter tubular scaffolds with high orientation and controllable porosity can be prepared;

-Near-field direct writing micro-nano printing;

-Designed for mass production of biological tissue engineering scaffolds, in line with medical device standards.

Product Features

(1)Equipped with ø1~10mm 316 stainless steel tube collector can print tubular bracket, aspect ratio (L-850mm, p1-10mm);

(2)Equipped with room temperature ~ 300 ℃ melting nozzle;

(3)The temperature of the spinning chamber is controllable;

(4)The fiber diameter is controllable, small-diameter tubular scaffolds with high orientation and controllable porosity can be prepared;

(5)Near-field direct writing micro-nano printing;

(6)Designed for mass production of biological tissue engineering scaffolds, in line with medical device standards.

Product features

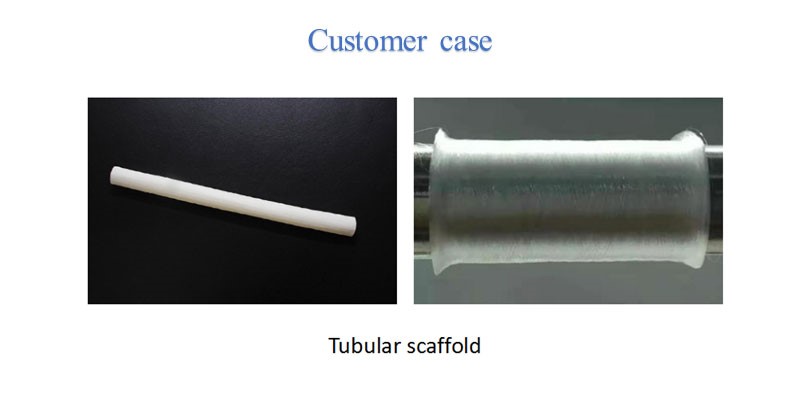

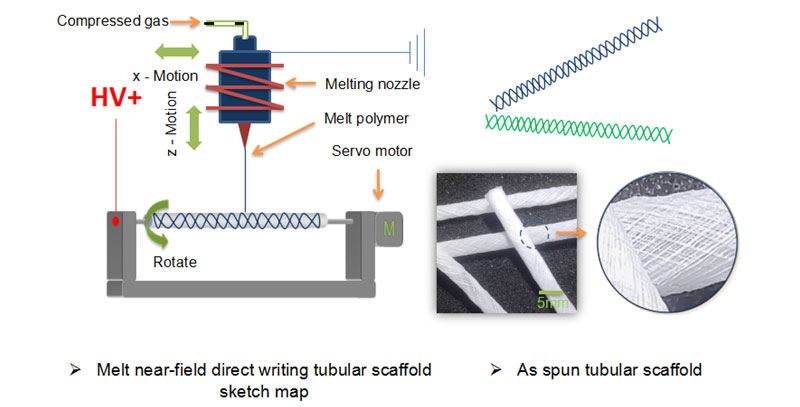

The near-field electrostatic direct writing device M08-002 is designed for batch preparation of tissue engineering scaffolds. The orderly fiber structure can be prepared by near-field direct writing technology, and small-diameter artificial vascular stents can be prepared, with an ultra-long receiving stroke of 850 mm, and melt spinning to solve the problem of solvent residues. The product complies with the standards related to medical devices. A tubular stent with a high degree of orientation and controllable porosity can be prepared. Equipped with a high-precision mobile platform, the diameter of the clamping stick can be ø1~10mm.

Electrospinning equipment M08-002 parameter

(1)Size: 120*80*180cm;

(2)High voltage power supply: 0~30Kv.

(3)Melt nozzle: the heating temperature can reach 300℃; the minimum adjustable high-precision pressure regulating valve is 0.01Mpa; the adjustable range is 0~0.4Mpa.

(4)Tube collector: effective length 850mm; Diameter: Ø1~10mm; Speed: 0~300r/min.

(5)Environmental parameters: ambient temperature control: room temperature ~ 50 ℃, accuracy ± 3%; Exhaust air volume: 0.5m³/min.

(6)Electrospinning Materials: Most polymer materials such as PCL, PBAT, PLLA, TPU, PEO, etc.

Electrospinning equipment M08-002 application

The structure of the electrospinning nanofiber membrane scaffold is similar to that of the extracellular matrix, which is conducive to the adhesion and growth of cells and can promote cell contact, penetration, and maintain the stability of the cell structure so that cells can grow directionally along the fibers. Electrospinning nanofiber membranes are mostly used in:

(1) Small-caliber artificial blood vessels;

(2) Intestinal scaffold;

(3) Urethral scaffold;

(4) Tubular cell growth scaffold;

(5) Spinal cord scaffold wrapping material.