Copyright © 2022 Foshan MBRT Nanofiberlabs Technology Co., Ltd All rights reserved.Site Map

Electrospinning is a technique for preparing nanofibers, which can produce fibers with nanoscale diameters. It is a process in which a high voltage electrostatic field is used to eject a polymer solution, which is then collected on a receiver as fibers. Electrospinning technology has the following advantages.

Efficient preparation of nanofibers

Electrospinning technology can quickly and efficiently produce nanoscale fibers. Fibers with nanoscale diameters can be prepared in seconds to minutes. This efficient method can be used for large-scale preparation of high-quality nanomaterials.

Control of nanofiber diameter

Electrospinning technology can control the diameter of the fibers. By controlling the concentration of the solution, the nozzle diameter, voltage, distance, and other parameters, fibers with different diameters can be produced. This controllable diameter feature makes electrospinning technology very valuable in the preparation of nanomaterials.

Adjustable structure

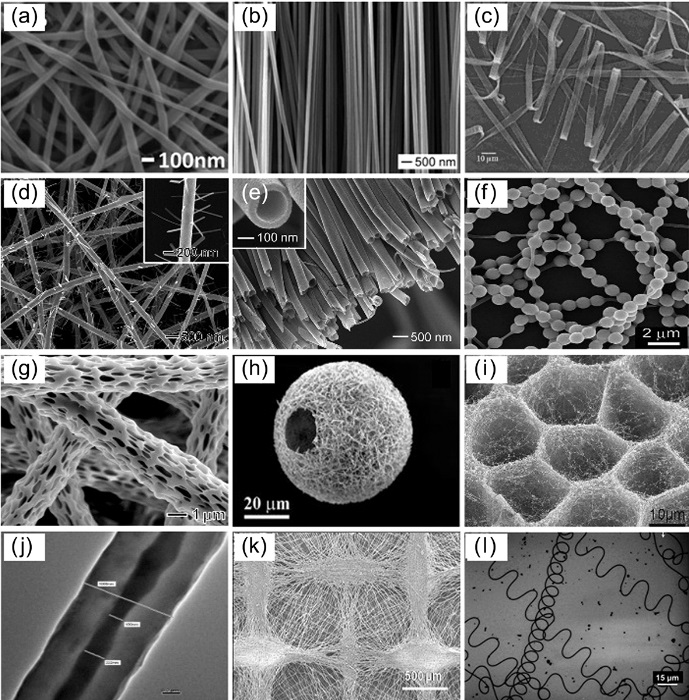

Electrospinning technology can change the structure and shape of fibers by controlling the composition and flow rate of the solution. Different solution formulations and processing conditions can produce different forms of fibers, such as nanotubes, nanorods, and nanonets. This adjustable structure feature makes electrospinning technology applicable in many fields.

Fig1 Morphologic structure of nanofibers under different electrospinning parameters

Excellent properties of nanofibers

Nanofibers prepared by electrospinning have unique physical and chemical properties, such as high surface area, high porosity, high stretchability, and high specificity. These properties make nanofibers widely applicable in various fields, such as energy storage, catalysis, sensors, medicine, and the environment.

Strong scalability

Electrospinning technology can be applied in various materials, such as polymers, inorganic materials, and biological materials, and has strong scalability. Therefore, it has great potential in many fields, such as biomedical, food packaging, and filters.

In conclusion, electrospinning technology has the advantages of high efficiency, controllable diameter, adjustable structure, excellent properties of nanofibers, and strong scalability. In the future, it will play a more important role in more application fields. However, electrospinning technology also faces some challenges, such as the difficulty in controlling the process under high temperature, high pressure, and high voltage conditions, as well as issues related to the dispersion and stability of nanofibers. Therefore, continuous optimization and improvement of the technology are needed to improve its stability, reliability, and scope of application.

In response to these challenges, researchers have proposed some improvement measures in recent years, such as using multiple nozzles, changing the nozzle shape, controlling flow rate, changing the distribution of the electrostatic field, and combining electrospinning technology with other techniques such as heat treatment, chemical modification, and electrochemical synthesis to produce more functional nanomaterials.

In conclusion, electrospinning technology, as a fast and efficient method for preparing nanofibers, has many advantages and potential application values. Future research and development will further expand its application fields and solve the challenges it faces in engineering practice to achieve its broader and more effective application.