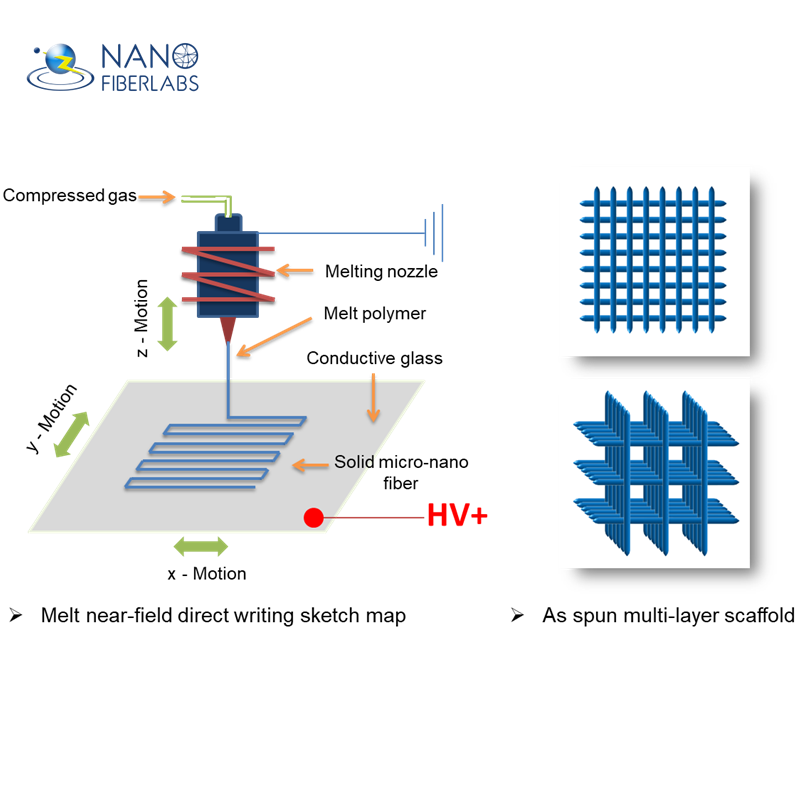

-High-voltage electrospinning, solution near-field direct writing, melt near-field direct writing, electrospray four-in-one;

-Equipped with room temperature ~ 300 ℃ melting nozzle;

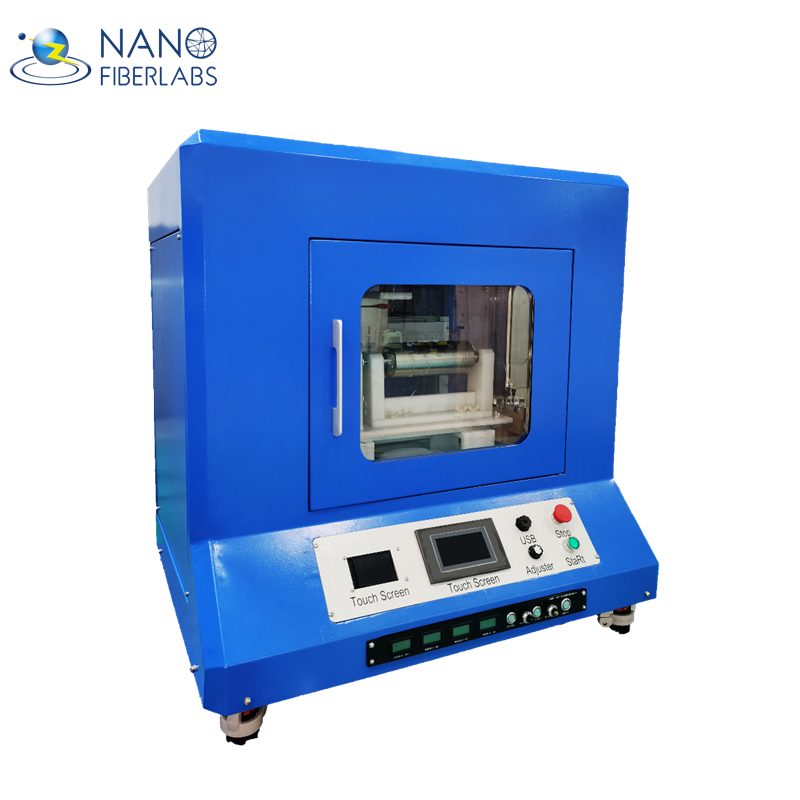

-Desktop nano-material processing center;

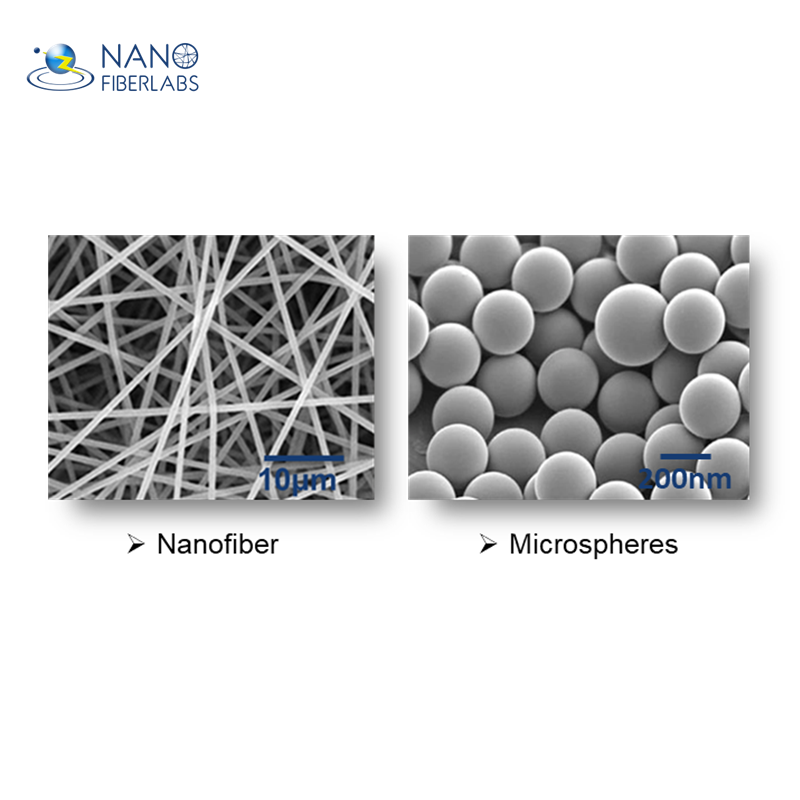

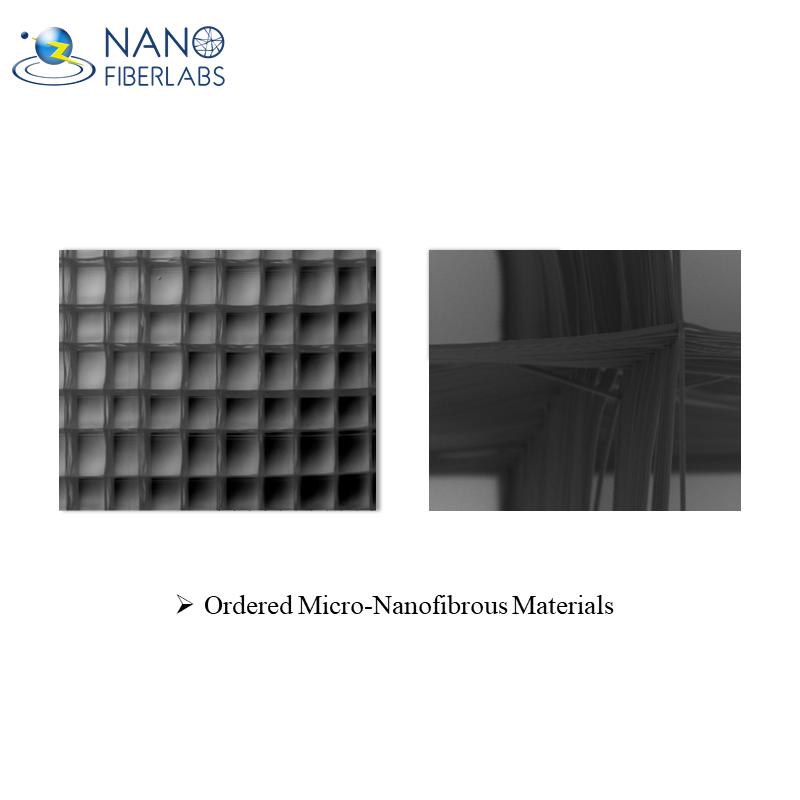

-Ordered micro/nanofibers/disordered micro/nanofiber membranes/nano microspheres can be prepared;

-Customizable pattern printing, support multiple path printing;

-Software assistance, support for importing print files;

-Preparation of 3D Electrospun Nanofiber Scaffolds for Tissue Engineering.

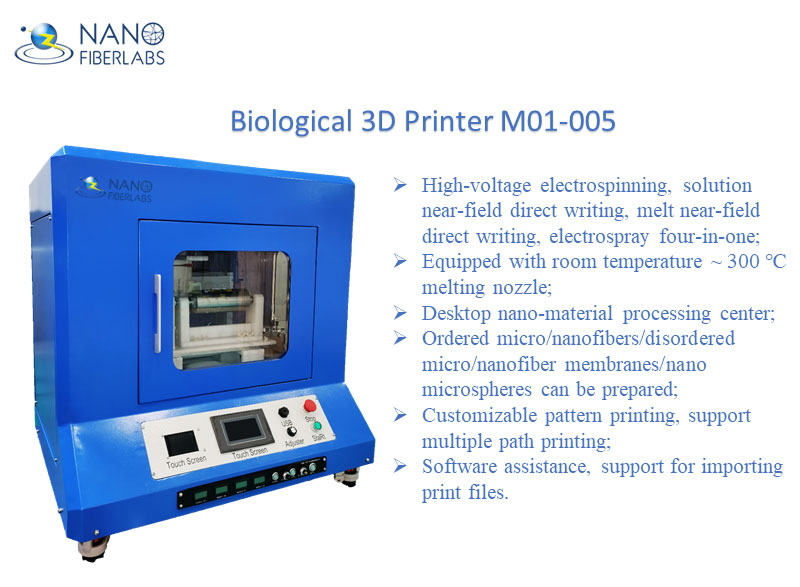

Product Introduction

The bio 3D printer M01-005 combines electrospinning, near-field electrospinning, melt electrowriting(MEW), and electrospray technology. The device can design micro-and nano-oriented fibers, disordered nanofiber membranes, and nano-microspheres, allowing the design of composite nanofiber materials. It is especially suitable for preparing scaffold materials for tissue engineering.

The device adopts a modular design and integrates nanomaterial processing technology. Modules can be replaced according to experimental needs, providing great flexibility for processing nanomaterials. In addition, with software assistance, you can customize the printing path and support a variety of patterned printing.

Product feature

(1) High-voltage electrospinning, solution near-field direct writing, melt near-field direct writing, electrospray four-in-one;

(2) Equipped with room temperature ~ 300 ℃ melting nozzle;

(3) Desktop nano-material processing center;

(4) Ordered micro/nanofibers/disordered micro/nanofiber membranes/nano microspheres can be prepared;

(5) Customizable pattern printing, support multiple path printing;

(6) Software assistance, support for importing print files;

(7) Preparation of 3D Electrospun Nanofiber Scaffolds for Tissue Engineering.

Product Parameters

(1)Electrospinning high voltage power supply: DC0~+30KV, current<1mA; DC0~-30KV, current<1mA;

(2)Melting nozzle: heating temperature up to 300℃;

(3)Pneumatic extrusion nozzle at room temperature: for high-viscosity materials at room temperature, it is equipped with a pneumatic feeding nozzle, and a high-precision pressure regulating valve can be adjusted at least 0.01Mpa; the biological clean barrel can be adapted to conventional extrusion needles;

(4)Collector: The effective collection range of the flat collector is 100mm×100mm;

(5)Optional functions: solution spinning liquid supply system; far-field drum receiving system; camera system; Air compressor.

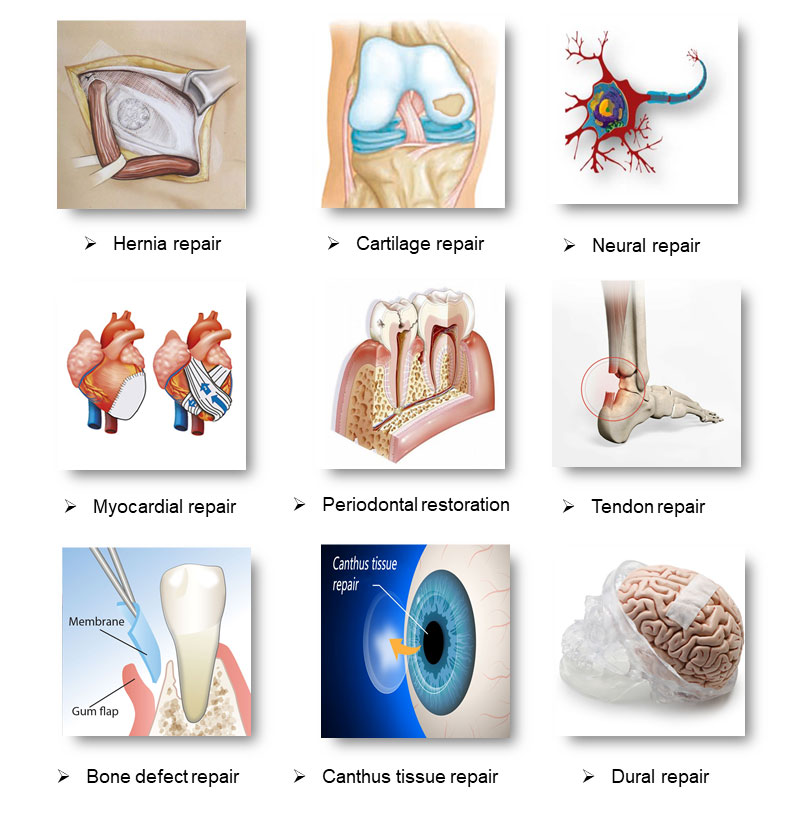

Product application

The morphology of electrospinning nanofibers is similar to that of the extracellular matrix and can be used to modulate cellular behavior and function. 3D electrospun nanofiber scaffolds can provide biomimetic structures for stem cells.

It has broad application prospects in the field of tissue repair for cartilage, bone, tendon, ligament, skeletal muscle, nerve and cardiac tissue regeneration.